Method for welding substrate and diaphragm of diaphragm-moving polymer microfluidic chip

A technology of microfluidic chip and welding method, which is applied in the direction of welding equipment, laser welding equipment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

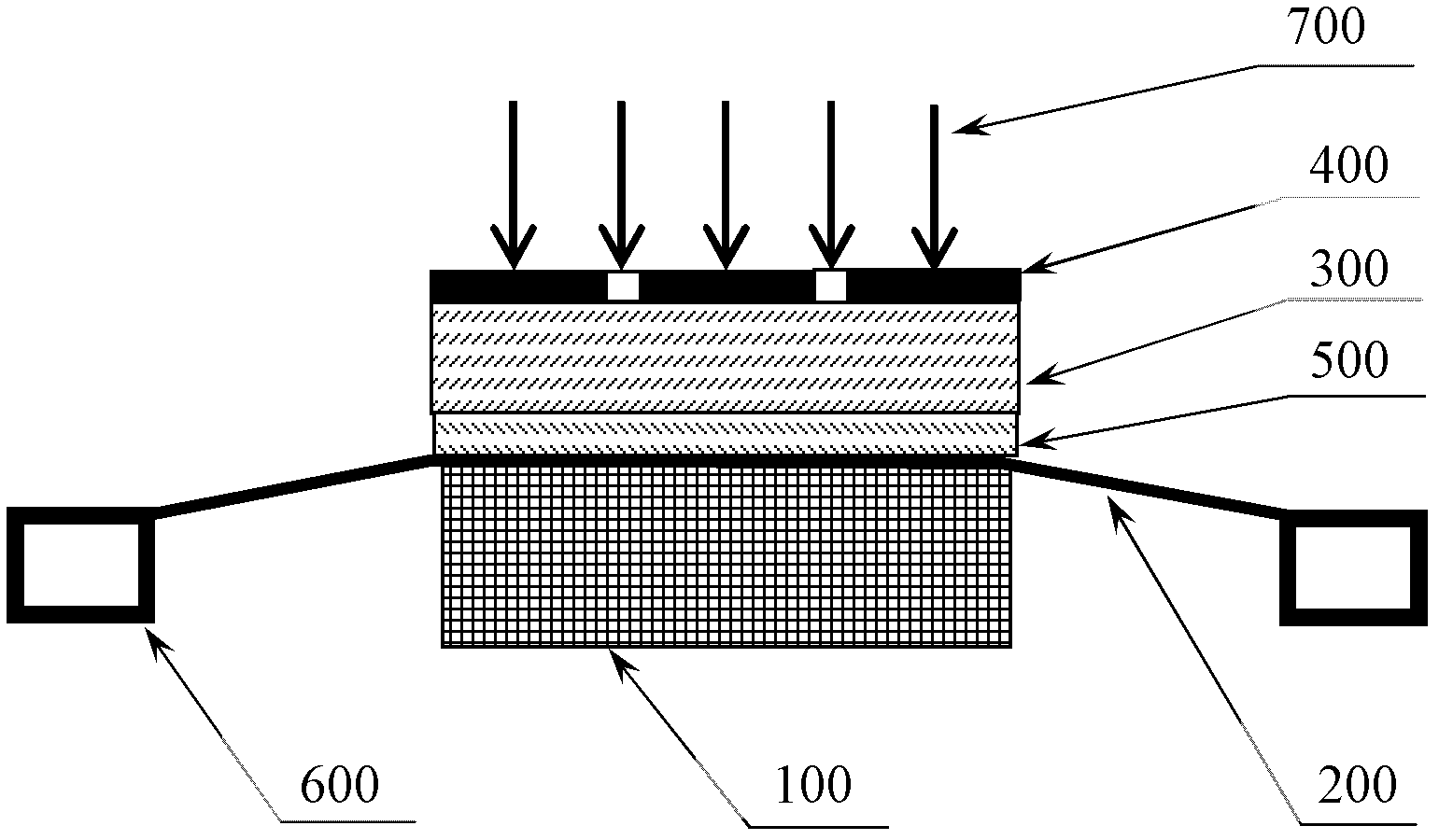

[0045] This embodiment provides a method for welding the substrate and diaphragm of a membrane-moving polymer microfluidic chip, such as figure 1 Shown is a schematic diagram of the welding structure using the welding method in this embodiment. Before welding, the substrate 100 is fixed, the diaphragm 200 is covered on the surface of the substrate 100, and pressure is applied to press the diaphragm 200 on the surface of the substrate 100. In this embodiment, a transparent pressure plate 300 is used to apply pressure to the diaphragm.

[0046]Preferably, in order to make the welding firm, a tensioning device 600 is used to apply a certain tension to the diaphragm 200 , and the stretched diaphragm 200 covers the surface of the substrate 100 . When the pressure is applied, the tension is adjusted according to the elastic parameters of the diaphragm 200 and the applied pressure. Since the diaphragm 200 is tightened, the substrate 100 bears against the diaphragm 200 from below, so ...

Embodiment 2

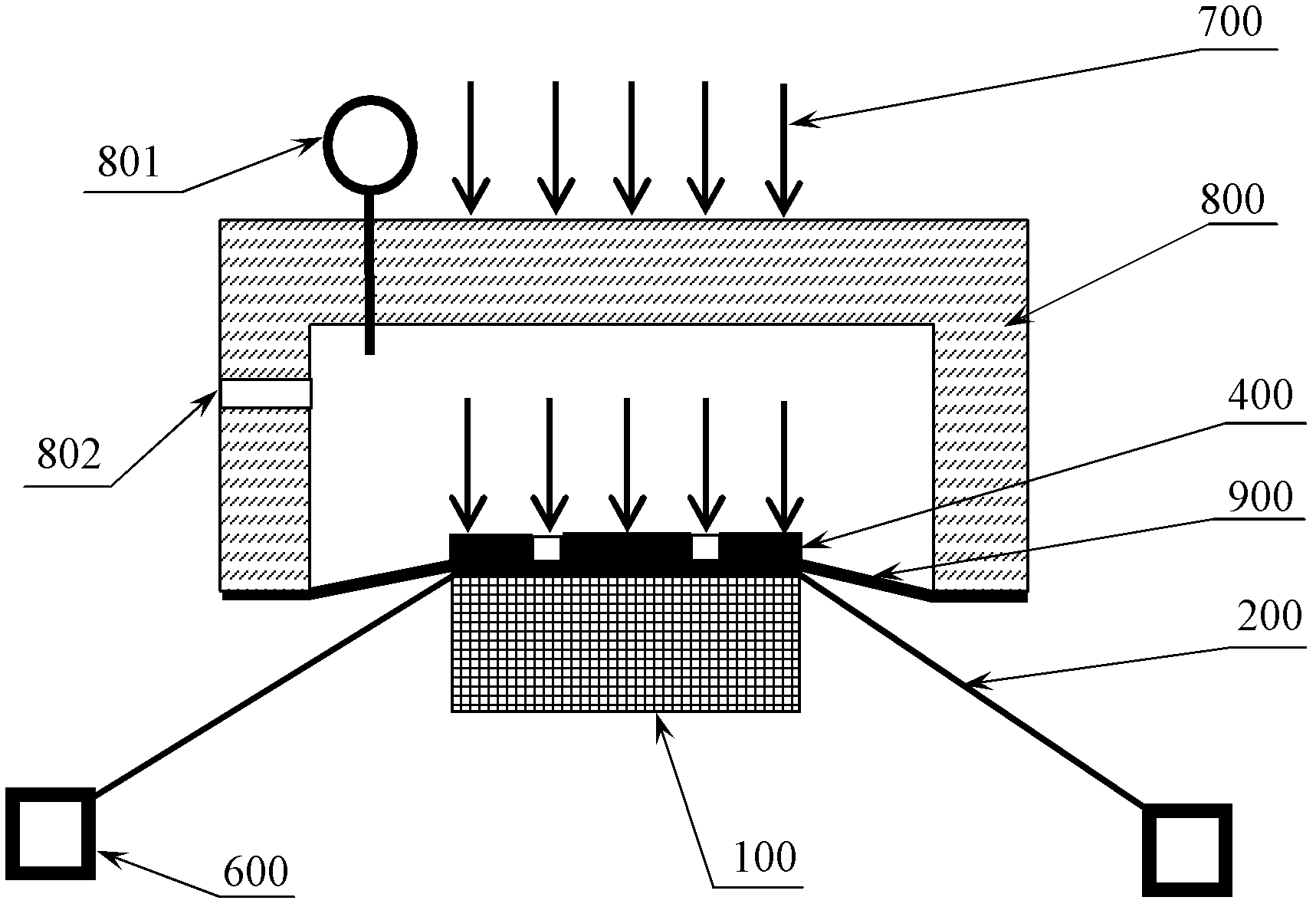

[0051] This embodiment provides a method for welding the substrate and diaphragm of a membrane-moving polymer microfluidic chip, such as figure 2 Shown is a schematic diagram of the welding structure using the welding method in this embodiment. The welding steps are basically the same as in Embodiment 1, the difference is the way of applying pressure to the diaphragm 100 . In this embodiment, pressure is applied to the diaphragm 100 by means of air pressure-compression film. Before welding, the substrate 100 is fixed, and the diaphragm 200 covers the surface of the substrate 100 . Preferably, the tensioning device 600 is used to stretch the diaphragm 200 to cover the surface of the substrate 100 . The barometric chamber 800 and pressure film 900 are placed on the surface of the diaphragm 200 , the pressure film 900 seals the barometric chamber 800 in advance, and the body of the barometric chamber 800 is provided with a pressure sensor 801 and a control valve 802 . When ap...

Embodiment 3

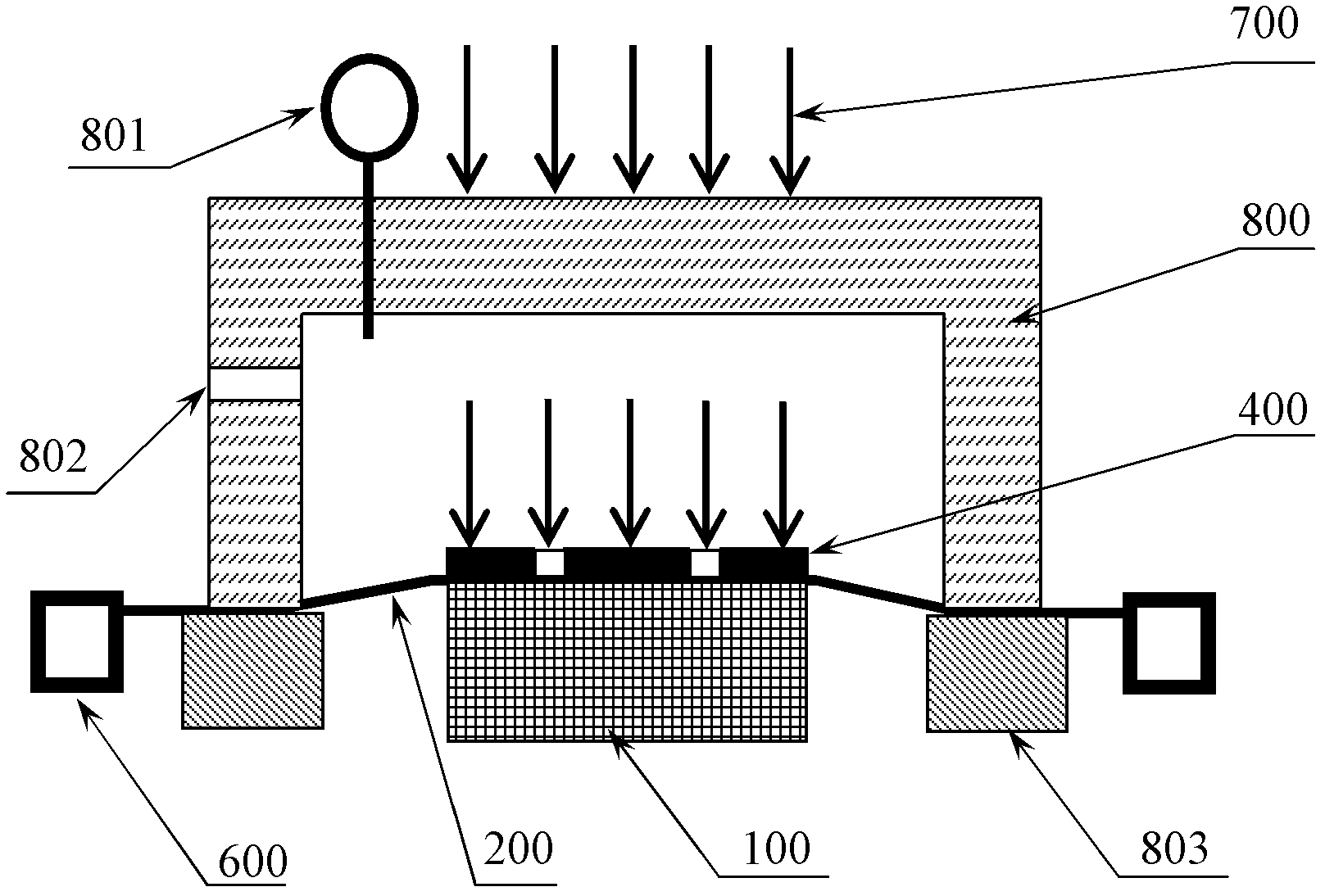

[0058] Such as image 3 As shown, the welding method of the substrate and diaphragm of the membrane-moving polymer microfluidic chip provided in this embodiment is basically the same as that of Embodiment 2, the difference is that the pressure chamber 800 is not sealed with a pressure film, but the substrate 100 and the diaphragm are placed After 200 minutes, the diaphragm 200 is pressed tightly around the air pressure chamber 800 through the sealing seat 803 matched with the air pressure chamber 800 to seal the air pressure chamber 800 . Preferably, before sealing, the tensioning device 600 is used to apply tension to the diaphragm 200 to make it tight. The way of applying pressure is the same as in Example 2.

[0059] Preferably, when inflated, the tensile force is adjusted according to the elastic parameters of the diaphragm 200 and the air pressure, so as to control the tensile deformation and ensure the welding quality. In this embodiment, since the diaphragm 200 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com