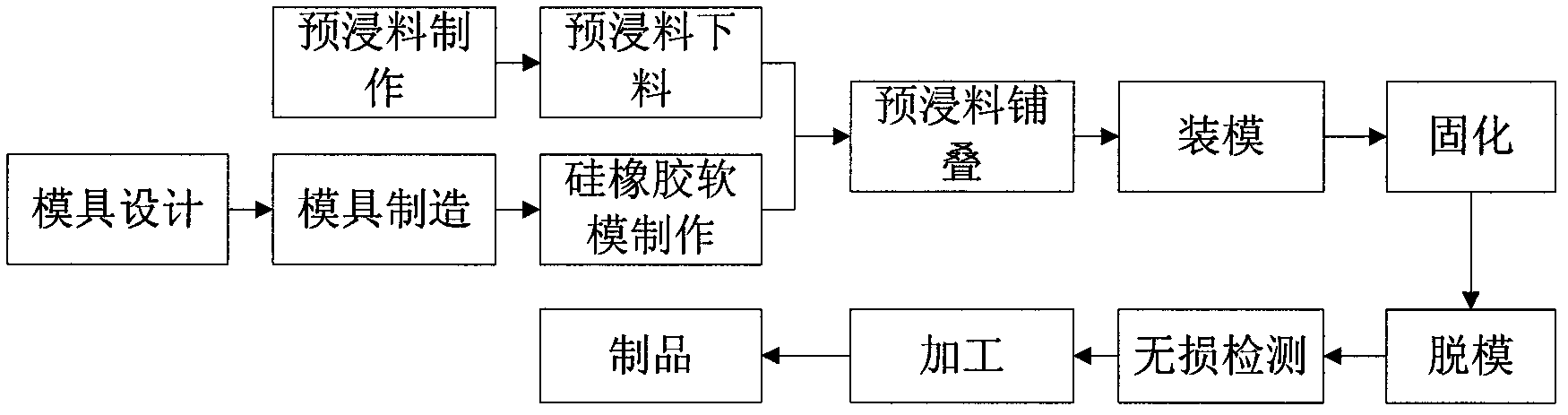

Forming process of curved composite tube

A composite material pipe and molding process technology, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve problems such as research and application reports of composite material pipes that have not seen curves, achieve good structural quality efficiency, and meet dimensional accuracy requirements. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of carbon fiber composite material is given below, which can be designed according to the specific product performance and structure in actual production, and its specific performance and index are different according to different prepregs and different preparation methods.

[0053] The carbon fiber material is impregnated with a certain amount of resin glue to make a dry-process resin-based composite material prepreg. The reinforcement material is carbon fiber, and the resin matrix is epoxy resin.

[0054] The resin system is epoxy resin, which is made into dry or wet resin-based composite material prepreg, in which the mass of wet prepreg resin accounts for 40%-46% of the total mass of the mixture; the mass of dry prepreg resin accounts for the mixture 32%-38% of the total mass.

[0055] The quality index requirements of composite material wet prepreg are shown in Table 1.

[0056] Table 1 Quality index of composite material wet prepreg

[...

Embodiment 1

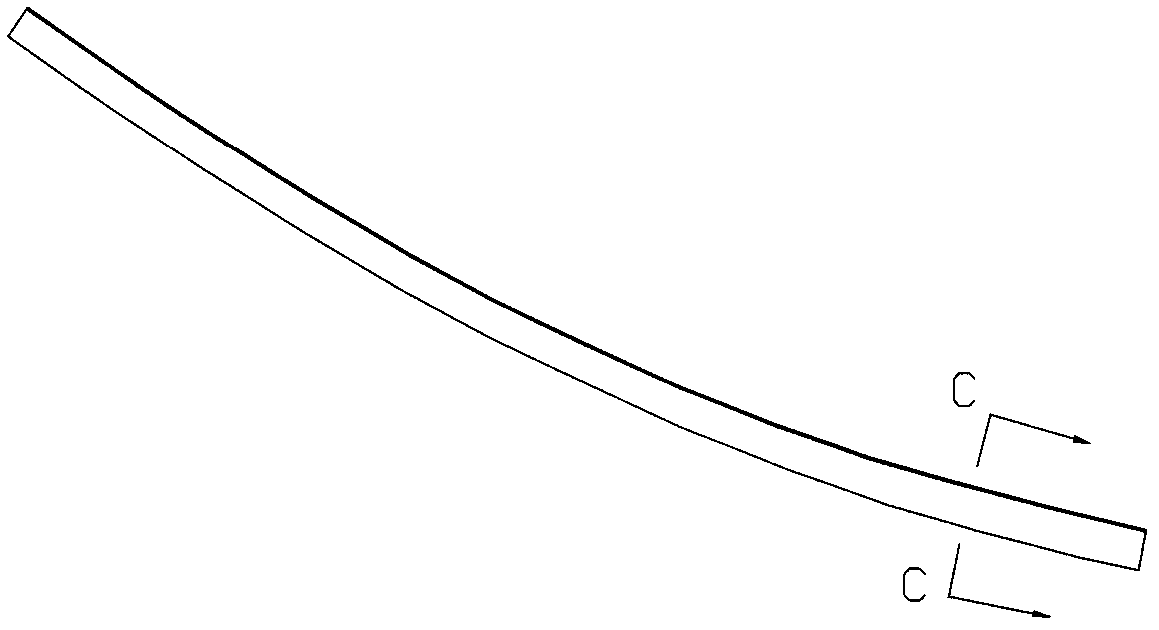

[0079] Product Name: Radial Ribs for Reflective Surfaces

[0080] Size: focal length 1400mm, length 1600mm

[0081] The implementation steps are as follows:

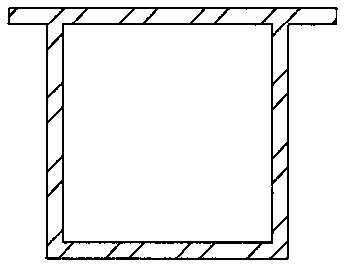

[0082] (1) The mold is designed as a closed, combined hard mold and silicone rubber soft mold, and the product molding pressure is 0.5MPa.

[0083] (2) Cast the silicone rubber soft mold and perform post-treatment in an oven. The heating rate is 20°C-40°C / h, the post-treatment temperature is 180±5°C, and the post-treatment time is 3h. After cooling down to room temperature with the furnace, the post-treatment is completed.

[0084] (3) The glue content of the dry prepreg is 35±3%, the volatile matter is controlled within 1%, and the surface density of the prepreg is 165±5g / m 2 , thickness 0.15mm, width 800mm.

[0085] (4) Use an automatic cutting machine for cutting.

[0086] (5) Lay multiple layers of carbon fiber prepregs on the forming mold to form a laminate of composite prepregs.

[0087] (6) Autoclave forming:...

Embodiment 2

[0090] Product Name: Radial Ribs for Reflective Surfaces

[0091] Size: focal length 1400mm, length 1600mm

[0092] The implementation steps are as follows:

[0093] (1) The mold is designed as a closed, combined hard mold and silicone rubber soft mold, and the product molding pressure is 0.3MPa.

[0094] (2) Cast the silicone rubber soft mold and perform post-treatment in an oven. The heating rate is 20°C-40°C / h, the post-treatment temperature is 180±5°C, and the post-treatment time is 3h. After cooling down to room temperature with the furnace, the post-treatment is completed.

[0095] (3) The glue content of the dry prepreg is 35±3%, the volatile matter is controlled within 1%, and the surface density of the prepreg is 165±5g / m 2 , thickness 0.15mm, width 800mm.

[0096] (4) Use an automatic cutting machine for cutting.

[0097] (5) Lay multiple layers of carbon fiber prepregs on the forming mold to form a laminate of composite prepregs.

[0098] (6) Molding in an oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com