Formula for solvent-free impregnating varnish

A solvent-free impregnating paint and formula technology, applied in polyester coatings, coatings, etc., can solve the problems of easy agglomeration and scrapping, increase in viscosity of paint liquid, etc., and achieve high adhesion, excellent electrical performance, and good moisture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

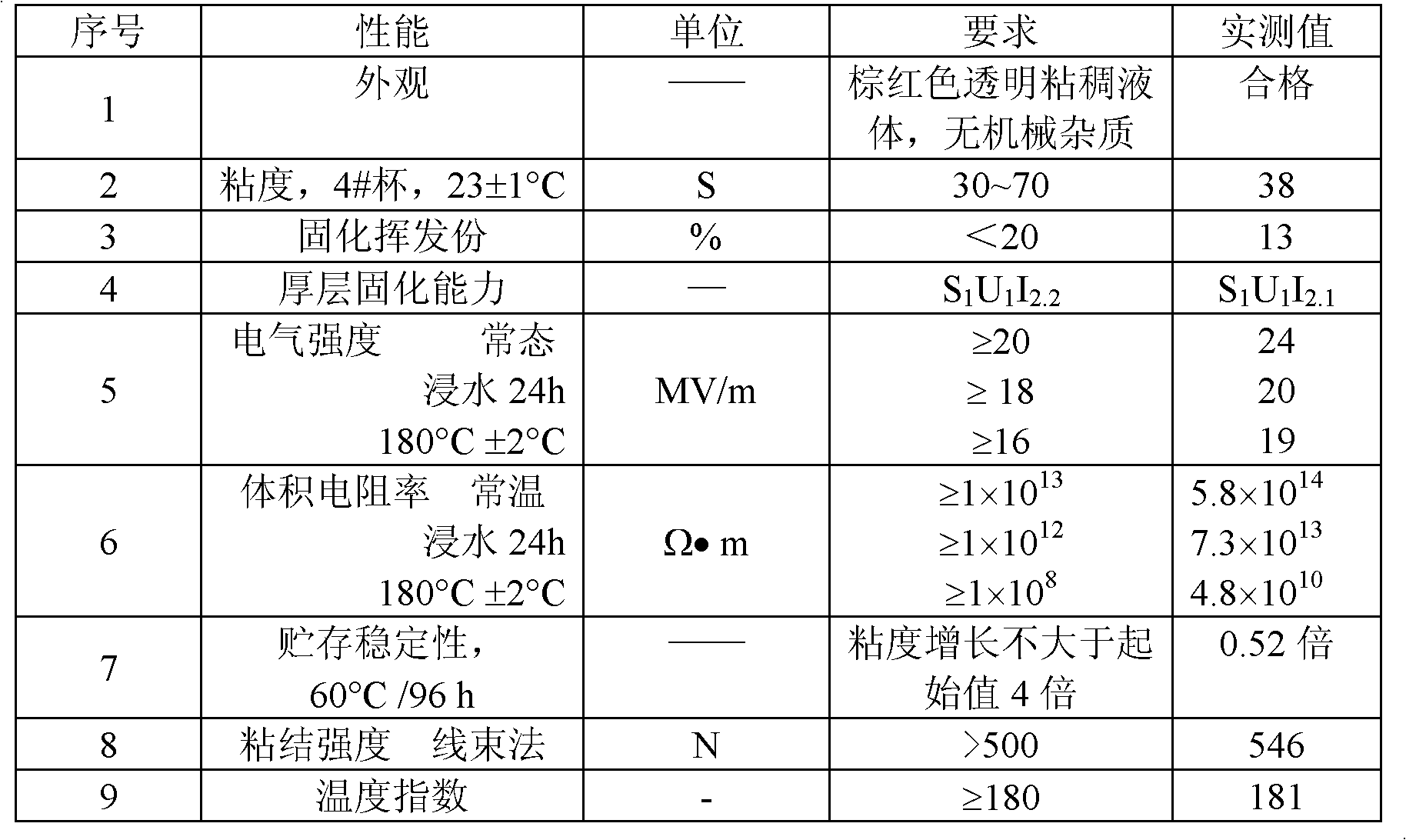

Examples

Embodiment 1

[0014] The solvent-free dipping varnish formulation of the present embodiment comprises the following components according to mass percentage:

[0015] 308 heat-resistant unsaturated polyester resin 55%; F44 epoxy resin 12%; accelerator 0.04%; hydroquinone 0.01%; initiator 0.95%; styrene 32%.

[0016] Above-mentioned accelerator is p-toluenesulfonic acid; Above-mentioned initiator is dicumyl peroxide.

Embodiment 2

[0018] The solvent-free dipping varnish formulation of the present embodiment comprises the following components according to mass percentage:

[0019] 308 heat-resistant unsaturated polyester resin 57%; F44 epoxy resin 10%; accelerator 0.06%; hydroquinone 0.01%; initiator 0.93%; styrene 32%.

[0020] Above-mentioned accelerator is p-toluenesulfonic acid; Above-mentioned initiator is dicumyl peroxide.

Embodiment 3

[0022] The solvent-free dipping varnish formulation of the present embodiment comprises the following components according to mass percentage:

[0023] 308 heat-resistant unsaturated polyester resin 60%; F44 epoxy resin 8%; accelerator 0.05%; hydroquinone 0.01%; initiator 0.1%; styrene 31.84%.

[0024] Above-mentioned accelerator is p-toluenesulfonic acid; Above-mentioned initiator is dicumyl peroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com