Multi-section foundation of wind driven generator weathered rock

A wind power generator, multi-section technology, applied in infrastructure engineering, buildings, sheet pile walls, etc., can solve the problems of natural environment damage, waste of raw materials and funds, damage to rock formations, etc., to achieve simple operation and reduce damage degree, the effect of bearing capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

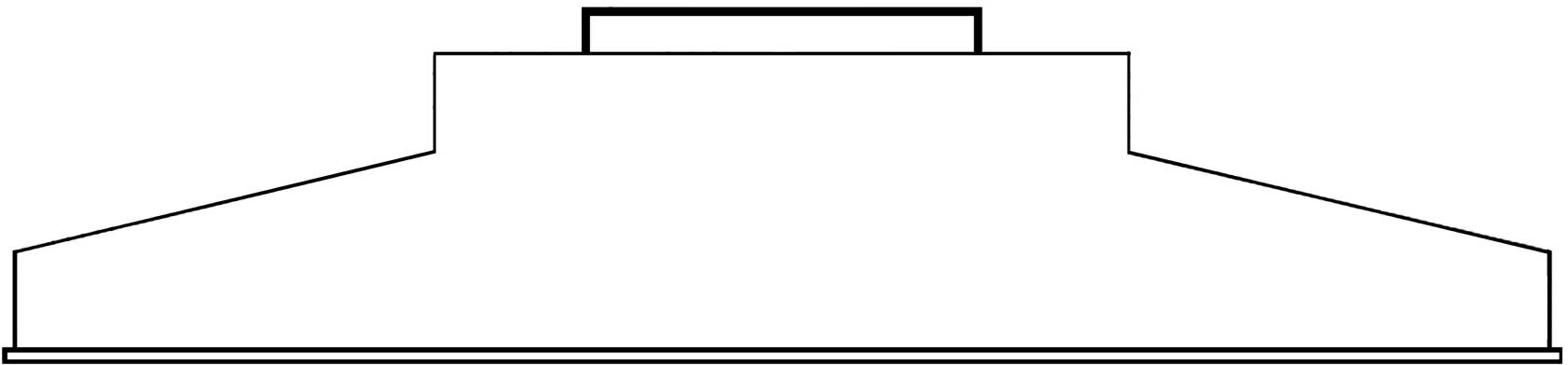

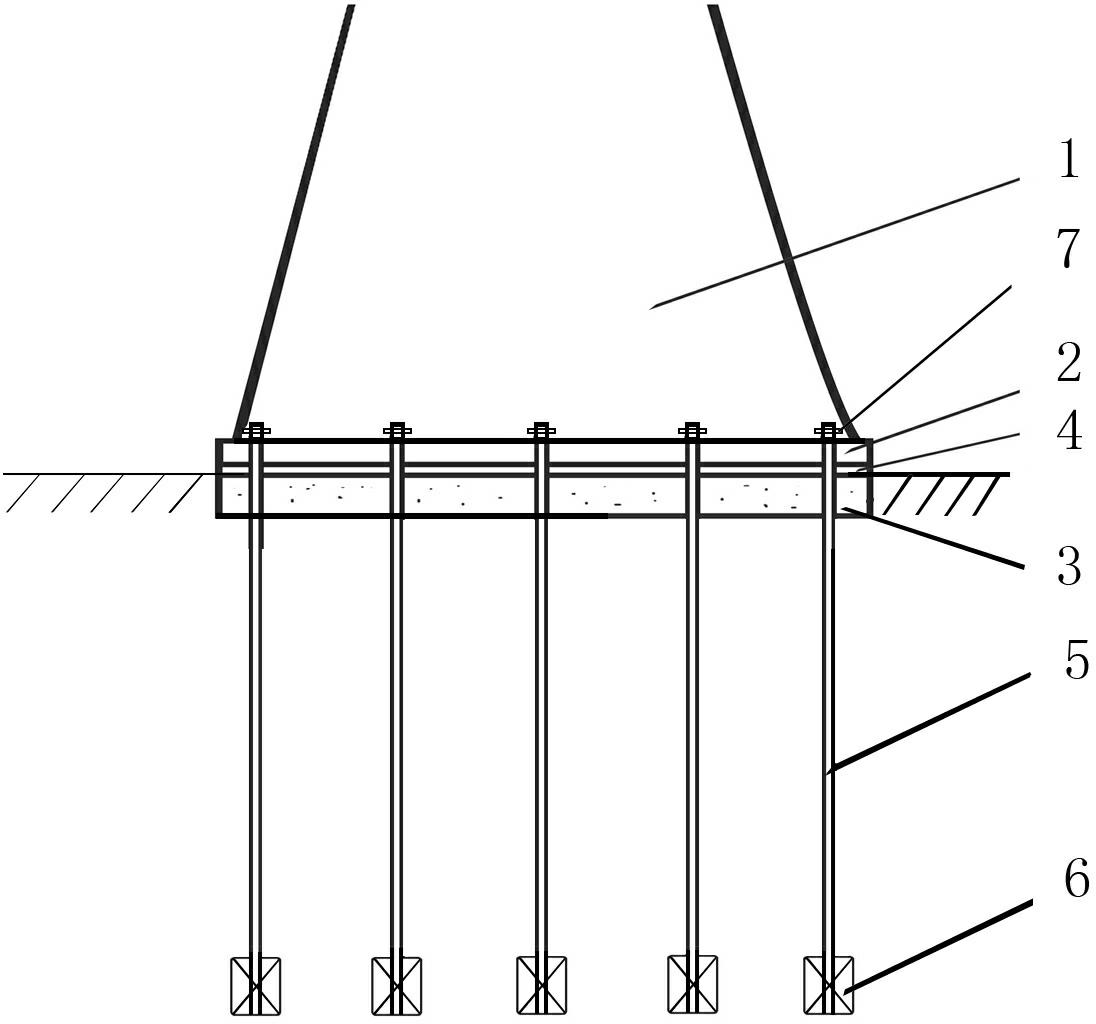

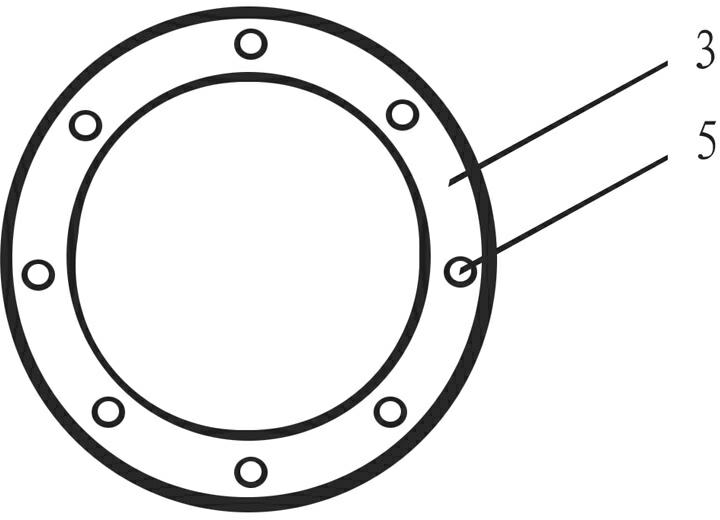

[0022] like Figure 2-Figure 3 as shown, figure 2 It is a structural schematic diagram of the present invention, image 3 It is a top view of the bearing platform in the present invention.

[0023] The present invention is a multi-section foundation of weathered rock formations for wind power generators. It is a foundation method in which a fan flange 2 is fixedly connected to the bottom of the fan cylinder 1, and the foundation flange 4 on the concrete bearing platform 3 and the fan flange 2 are firmly connected by bolts. Lan 4 is located above ground level. A plurality of anchor rods 5 are connected by nuts 7 through the foundation flange and the fan flange. One week of bearing platform 3 is vertically provided with a plurality of anchor rods 5, and the bottom of expanded bottom anchor rod 5 is provided with diameter-expanding cylinder 6.

[0024] During concrete implementation, 40 anchor rods can be established.

Embodiment 2

[0026] The bottom expansion anchor rod 5 of the present invention is arranged inclined outwards, and its inclination can be 10 degrees, 15 degrees, 20 degrees, 25 degrees...60 degrees.

[0027] There is no flange on the concrete cap 3, only a screw is provided on the concrete cap 3, and the bolts on the flange 2 of the fan base can be directly connected through nuts. Others are the same as implementation example 1.

Embodiment 3

[0029] like Figure 4 as shown, Figure 4 It is a structural schematic diagram of another embodiment of the present invention.

[0030] Both the middle part and the bottom of the expanded bottom anchor rod 5 according to the present invention are provided with enlarged diameter cylinders 6 to resist the horizontal thrust. Others are the same as implementation example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com