Light guide for delivering radiation and method of manufacture

A light guide and optical fiber technology, applied in the field of manufacturing the light guide, can solve the problems of deformation, mechanical strength drop, inability to know, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

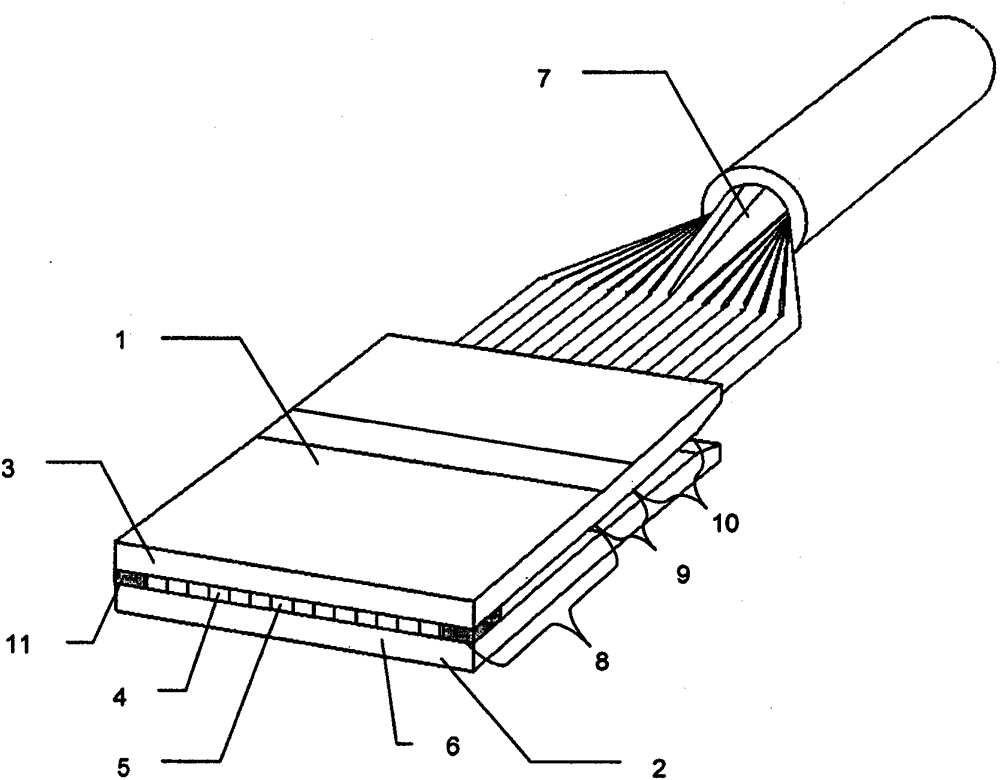

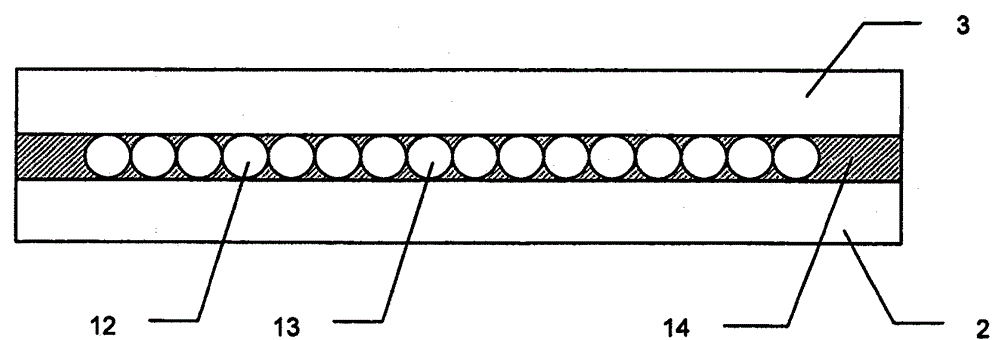

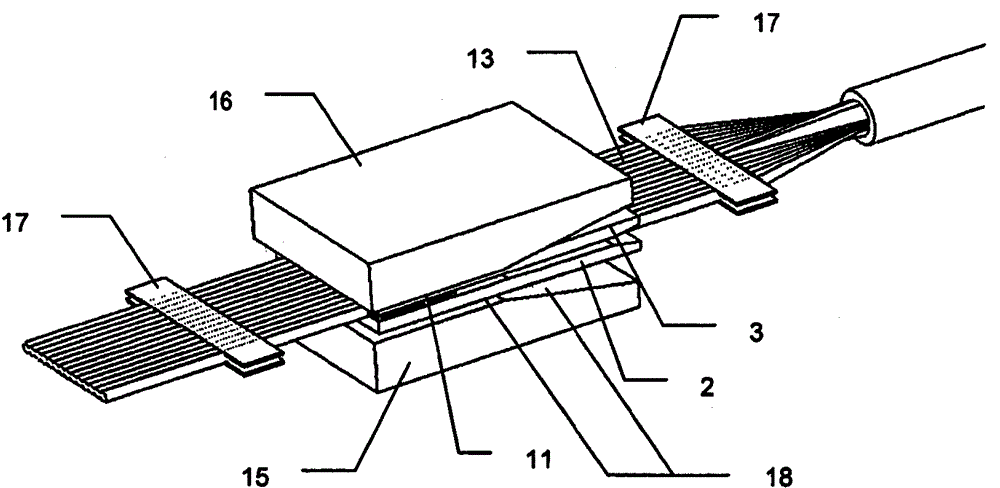

[0061] For illustration purposes, only schematic representations are used in the drawings and true dimensional relationships are not reflected to scale. The number of optical fibers is also matched for illustration purposes. Other non-essential elements, such as plug housings, etc., are likewise omitted in the illustration.

[0062] exist figure 1 The perspective view of the light guide according to the invention shows the coupling-in end (1), the coupling-in end comprising the carrier plate (2), the fiber deformed on the end face (6) of the coupling-in end and positively connected (4,5) and cover plate (3). Spacers ( 11 ) are arranged on both sides of the fibers, and these spacers are in planar contact with the carrier plate and the cover plate after the hot pressing process. These spacers are located laterally of the fiber strip and extend in the direction of the fibers only over the area or partial area of the fusion zone ( 8 ). A transition zone (9) and a lead-out zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com