Process for cold pressing tea seeds to produce oil

A technology of camellia oleifera seed and camellia oleifera seed shell, which is applied in the field of oil production process of camellia oleifera seed oil, which can solve the problems of solvent consumption affecting the extraction efficiency of leaching oil, high solvent content of wet meal, and locking of oil press, so as to avoid intensified friction The high temperature affects the quality of oil, the quality of finished oil is high, and it is beneficial to the effect of oil output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This embodiment discloses a process for making oil from camellia oleifera seeds by cold pressing, which includes the following steps:

[0040] (1) clean up

[0041] Vibrating with a two-layer vibrating sieve to remove large and small impurities in the raw material for oil extraction of camellia oleifera seeds to obtain pure camellia oleifera seeds; wherein the large impurities are mainly uncracked camellia oleifera (or called tea bags). Of course, other methods can also be used to remove impurities, as long as the impurities can be removed to facilitate subsequent processes and improve the quality of refined oil.

[0042] (2) Low temperature drying

[0043] Use a flat-panel dryer to dry the pure Camellia oleifera seeds at low temperature, control the interlayer heating steam pressure at about 0.2MPa, and control the temperature within 70°C, and further dry the Camellia oleifera seeds with a moisture content of about 8% to a moisture content of 5%. about.

[0044] (3)...

Embodiment 2

[0064] The present embodiment is the best embodiment of the present invention, and the difference between the present embodiment and the embodiment is two points: 1, the weight ratio that keeps the camellia oleifera seed shell in the separated camellia seed kernel of described step (5) is 20 %. 2. The weight ratio of the water added in the step (7) is 1.5%.

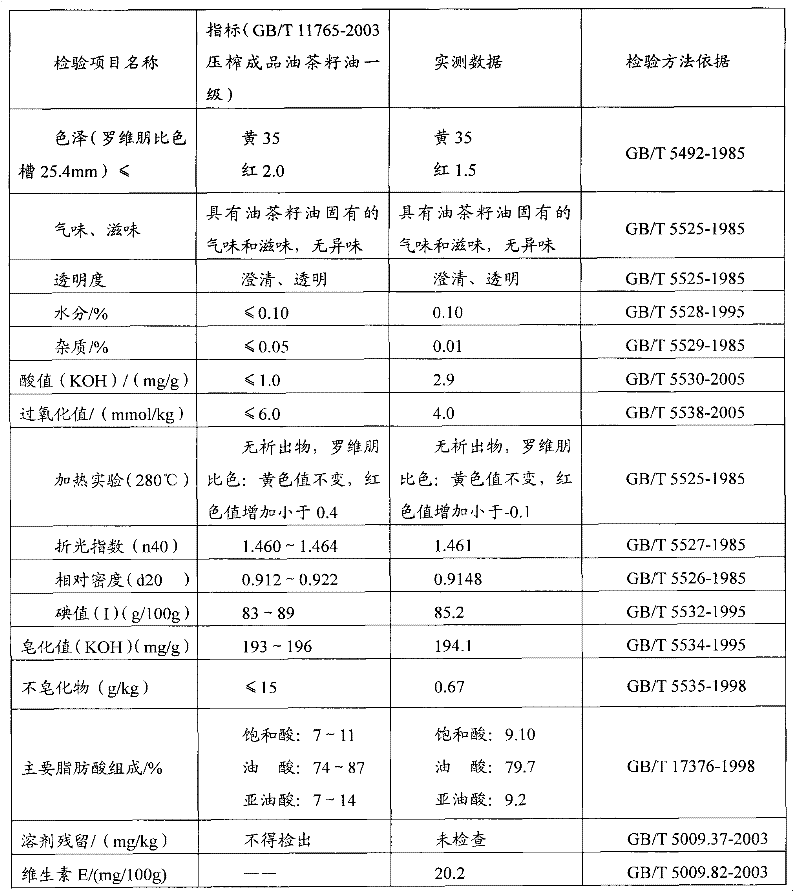

[0065] The following is the quality reference data of the tea seed oil obtained by pressing the camellia oleifera seed by adopting the process of the present invention:

[0066]

[0067] The whole process of the invention does not generate high temperature, realizes the real cold pressing of camellia oleifera seed oil, achieves mature technology, high efficiency and low cost. Through the separation of kernels and shells, the proportion of shells in the kernels is well grasped, and the materials to be pressed are tempered to effectively solve the problems of high oil yield of oil plants, temperature control in the cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com