Method for preparing orange chrome yellow pigment by recycling Cr<6+> from chromium residues

A technology of orange chrome yellow and pigment, which is applied in the field of resource utilization of hazardous solid waste chromium slag, and can solve the problem of secondary pollution of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

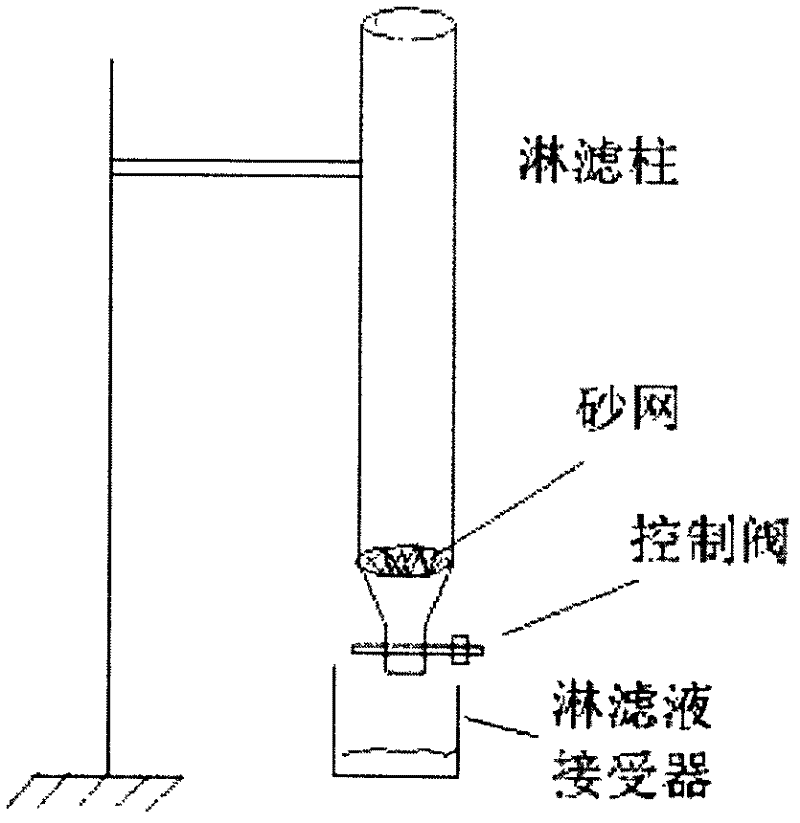

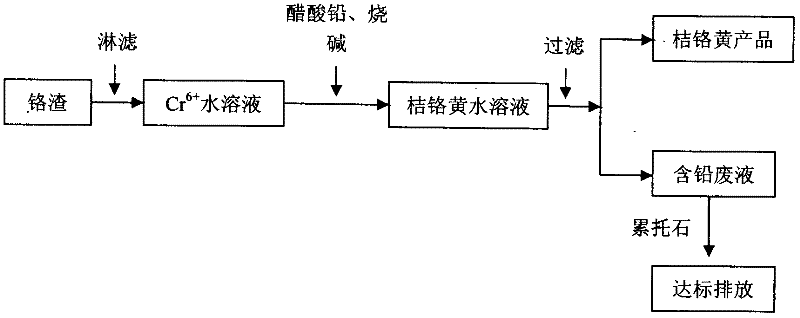

Method used

Image

Examples

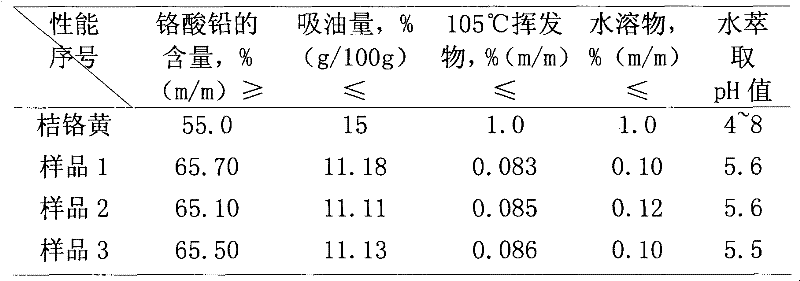

example 1

[0016] Taking the waste chromium slag of a factory as the research object, the leaching experiment was carried out to obtain Cr 6+ The concentration is 5.1g / L, pH=3.1, take 1L of Cr-containing 6+ Leaching water, according to weight ratio, lead acetate: Cr 6+ : caustic soda=24:10:1, at room temperature (22° C.), stirred and reacted for 10 minutes to form orange chrome yellow pigment suspension, which was filtered, aged, rinsed and dried to form orange chrome yellow product. Cr in filtered wastewater 6+ The concentration is 0.31mg / L, Pb 2+ The concentration is 2.1mg / L, Cr 6+ The effective recovery rate is 99.99%, including Cr 6+ The wastewater meets the effluent standard, and the Pb-containing 2+ Add rectorite to the wastewater, the pH is 5.6, the reaction time is 90min, the ratio of rectorite dosage to water is 15g / L, Pb 2+ Concentration dropped from 2.1mg / L to 0.04mg / L, Pb 2+ The removal rate reaches 98.1%. This kind of lead-containing wastewater meets the first-level s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap