Hexagonal-phase MoO2 nanosphere stacked micron hollow sphere and preparation method and application thereof

A hollow ball and nano ball technology, applied in the field of nanomaterials, can solve the problem of stacking micron hollow balls without nano balls, and achieve the effects of simple operation, excellent performance and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

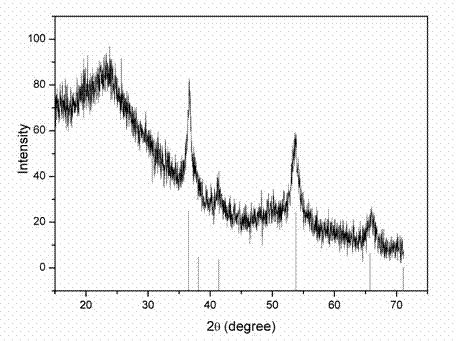

[0021] The hexagonal MoO 2 The specific steps of the preparation method of nano-stacked micron hollow spheres are:

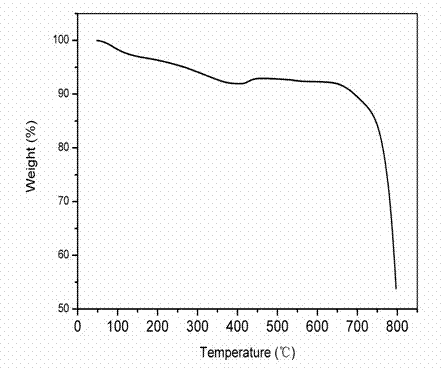

[0022] 0.5-1.5 g MoO 3 Add the powder into deionized water, add 0.05-0.5mL of diethylenetriamine, mix well, and react at 160°C-220°C for 3-6d, and then bake at 400-850°C for 2-8h under Ar atmosphere , that is, the hexagonal MoO 2 Nanospheres stack micron hollow spheres.

[0023] The added volume of the deionized water is 30-40mL.

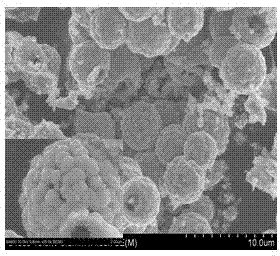

[0024] The micron hollow spheres are made of carbon-encapsulated hexagonal MoO 2 composed of nanospheres.

[0025] The diameter of the micron hollow sphere is 2-3 microns.

[0026] The hexagonal MoO 2 The application of nanospheres stacking micron hollow spheres is as a cathode material in lithium-ion batteries.

[0027] The lithium battery assembly method is: according to the mass ratio of the hexagonal phase MoO 2 Nano sphere stacking micron hollow sphere: polyvinylidene fluoride: acetylene black = 80: 10: 10 mixed and grou...

Embodiment 1

[0029] 0.5 g MoO 3 The powder was added to 30mL deionized water, and 0.05mL of diethylenetriamine was added, mixed evenly, and reacted at 160°C for 6d, and then calcined at 400°C for 8h under Ar atmosphere to obtain the hexagonal phase MoO 2 Nanospheres stack micron hollow spheres.

[0030] The parts not mentioned above are the same as the specific embodiments.

Embodiment 2

[0032] 1.5 g MoO 3 The powder was added to 40mL deionized water, and 0.5mL of diethylenetriamine was added, mixed evenly, and reacted at 220°C for 3d, and then calcined at 850°C for 2h under Ar atmosphere to obtain the hexagonal phase MoO 2 Nanospheres stack micron hollow spheres.

[0033] The parts not mentioned above are the same as the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com