Preparation method of fine-flash type aluminum pigment and aluminum pigment prepared by using same

A technology of aluminum pigment and fine flash, which is applied in the field of metallic pigments, can solve the problems of insufficient whiteness and brightness of fine flash aluminum pigment, and achieve the effect of uniform thickness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

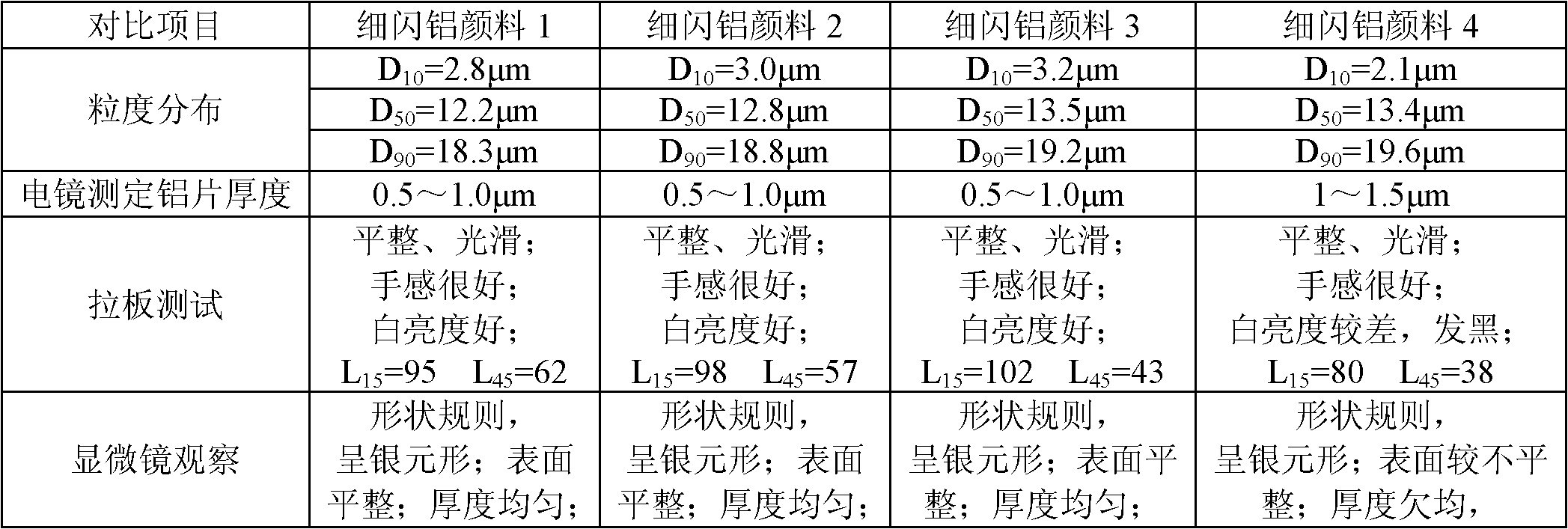

Embodiment 1

[0035] (1) Take D 50 40kg of atomized spherical aluminum powder with a diameter of 5μm, 70kg of 200# solvent oil, 1.8kg of linoleic acid, and 2.1kg of stearic acid were added to a horizontal ball mill, and steel balls with a diameter of 1.5mm were used as grinding media. Grind at 35 rpm for 42 hours and control the temperature of the outer wall of the ball mill to not exceed 60°C.

[0036] (2) Add 1 kg of lauric acid, grind for another 2 hours and stop.

[0037] (3) Afterwards, a filter cake with a solid content of 85±2% is obtained after discharging, screening, and pressure filtration, and the organic solvent obtained by pressure filtration is recycled. Then put it into a kneader, add 8.2kg of 150# solvent oil to dilute to a solid content of 68-72%, and knead to obtain a fine flash aluminum paste 1.

Embodiment 2

[0039] (1) Take D 50 37kg of atomized spherical aluminum powder of 7μm, 75kg of 200# solvent oil, 1.5kg of linoleic acid, and 1.4kg of stearic acid were added to a horizontal ball mill, and steel balls with a diameter of 2mm were used as grinding media at 35 rpm. The ball milling time is 36 hours at 10 minutes, and the temperature of the outer wall of the ball mill is controlled below 60°C.

[0040] (2) Add 1.2kg of lauric acid, grind for 2 hours and stop the machine.

[0041] (3) After discharging, sieving, and pressing to obtain a filter cake with a solid content of 83-87%, place it in a kneader, add 7.8kg of 150# solvent oil to dilute to a solid content of 68-72%, and knead Get fine flash type aluminum paste 2.

Embodiment 3

[0043] (1) Take D 50 46kg of atomized spherical aluminum powder of 10μm, 60kg of 200# solvent oil, 2.1kg of linoleic acid, and 2.4kg of stearic acid were added to a horizontal ball mill, and steel balls with a diameter of 3mm were used as grinding media at 35 rpm. The ball milling time is 44 hours at 10 minutes, and the temperature of the outer wall of the ball mill is controlled below 60°C.

[0044] (2) Add 1.2kg of lauric acid, grind for 1 hour and stop the machine.

[0045] (3) After discharging, sieving, and pressing to obtain a filter cake with a solid content of 83-87%, place it in a kneader, add 7.8kg of 150# solvent oil to dilute to a solid content of 68-72%, and knead Get fine flash aluminum paste 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com