Efficient and energy-saving repairing agent

A high-efficiency energy-saving, repairing agent technology, applied in the field of lubricating grease and lubricating oil, can solve problems such as instability, delamination effect, and dispersion defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

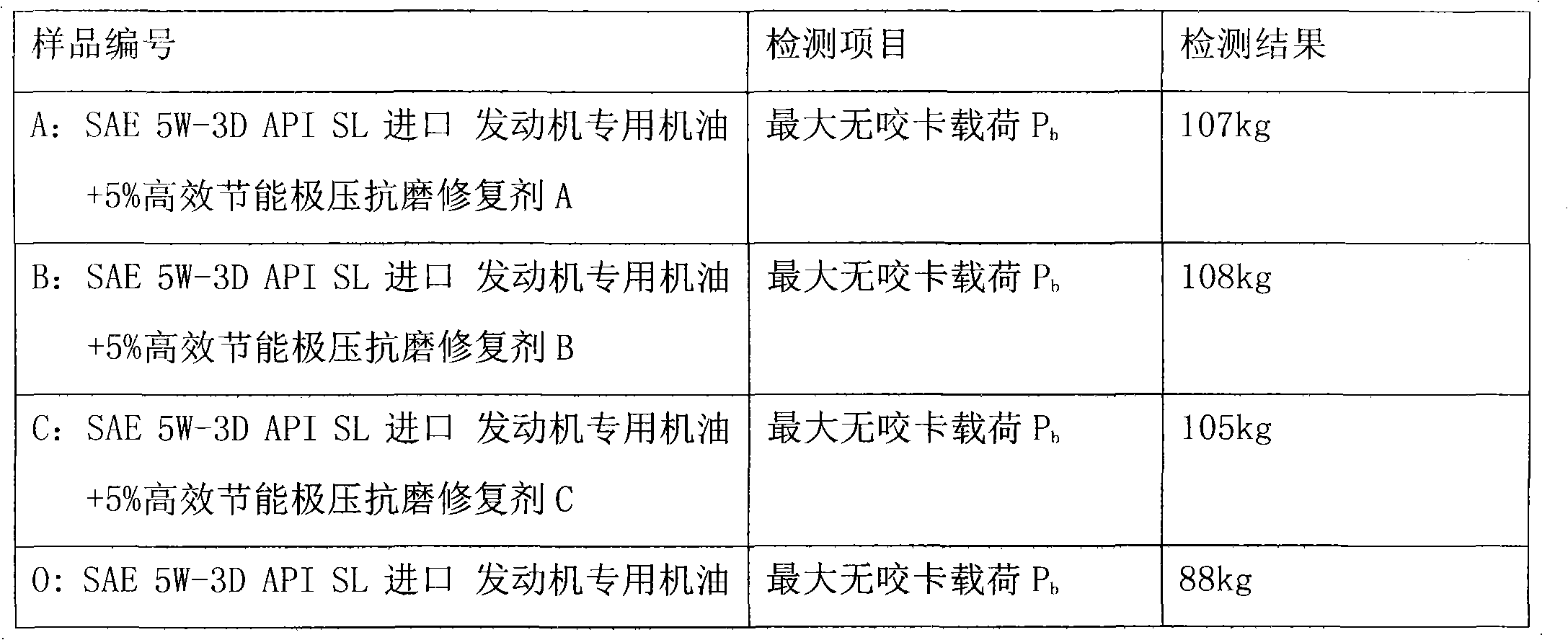

Examples

Embodiment Construction

[0023] 1. Borated alcohol amides

[0024] (1) Synthesis of borated ethanolamide

[0025] Add 120g of ethanolamine and 40g of boric acid into a three-neck flask with nitrogen protection and jacket heating, heat and stir until the boric acid is completely dissolved, then heat to 90°C, and react for 8 hours. The obtained product is a light yellow transparent liquid. In water and polar solvents.

[0026] (2) Synthesis of borated triethanolamide

[0027] Add 120g of triethanolamine and 40g of boric acid into a three-neck flask with nitrogen protection, jacket heating and stirring, heat and stir until completely dissolved, then heat to 95°C, and react for 8 hours. The obtained product is light yellow and transparent Liquid, soluble in water and polar solvents.

[0028] (3) Synthesis of borated anthranilamide

[0029] Add 120g of o-aminophenol and 40g of boric acid into a three-necked flask with nitrogen protection, jacket heating and stirring, heat and stir until completely diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com