Virtual instrument-based vehicle ABS (Antilock Brake System) test and control system and test method

A virtual instrument, measurement and control system technology, applied in the field of testing, can solve problems such as complex testing process, and achieve the effects of high test accuracy, good repeatability, and fast data collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

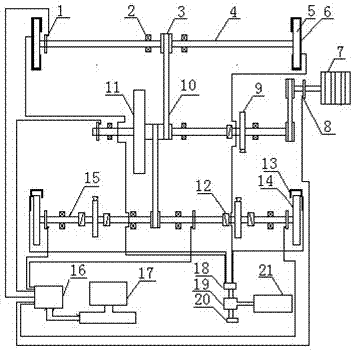

[0010] The overall structural block diagram of the automotive ABS measurement and control system based on virtual instruments is as follows: figure 1 As shown, it includes photoelectric speed sensor 1, bearing 2, pulley 3, rear axle 4, brake drum 5, brake cylinder 6, motor 7, motor speed sensor 8, magnetic powder clutch 9, belt 10, flywheel 11, coupling Shaft device 12, hydraulic regulator 13, brake disc 14, front axle 15, data acquisition card 16, PC 17, ABS control system 18, vacuum booster 19, brake pedal 20, vacuum pump 21, controlled by frequency converter The rotating speed of motor 7, motor 7 drives magnetic powder clutch 9 through pulley transmission, and magnetic powder clutch 9 drives pulley 3 through belt 10 and drags and connects the rotation of rear shaft 4 and bearing 2, and the rotation of rear shaft 4 drives the rotation of brake drum 5, making The moving drum 5 is connected to the brake cylinder 6, and the belt pulley drives the front axle 15 at the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com