Self-supporting nano-transmission grating with high duty ratio and manufacturing method thereof

A technology of transmission grating and duty ratio, applied in diffraction grating, optics, opto-mechanical equipment, etc., can solve the problems of high cost and complicated process, and achieve the effect of reducing processing cost, improving diffraction efficiency and improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

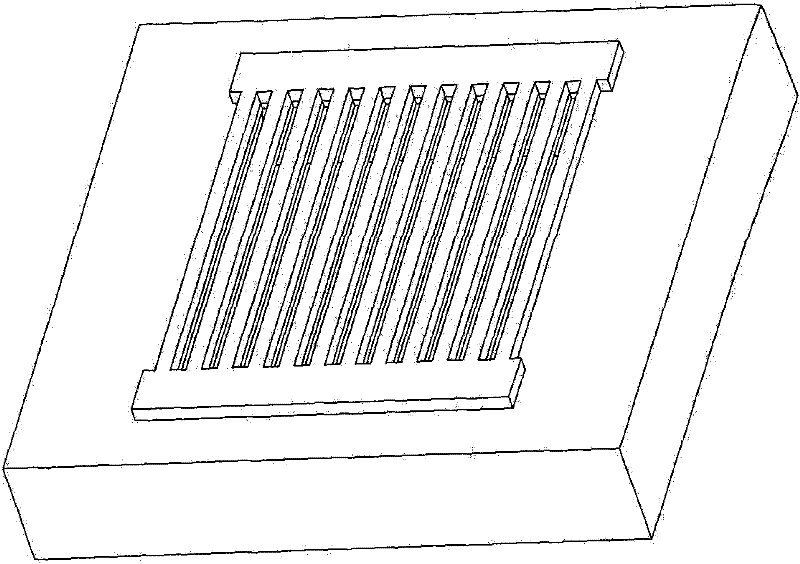

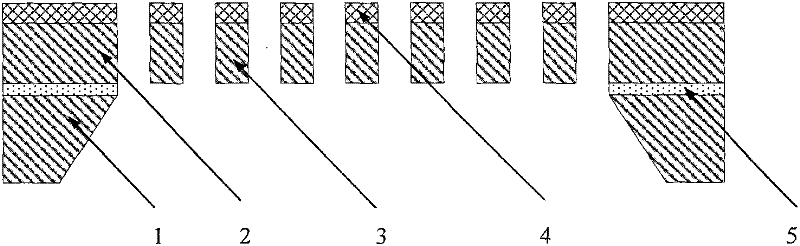

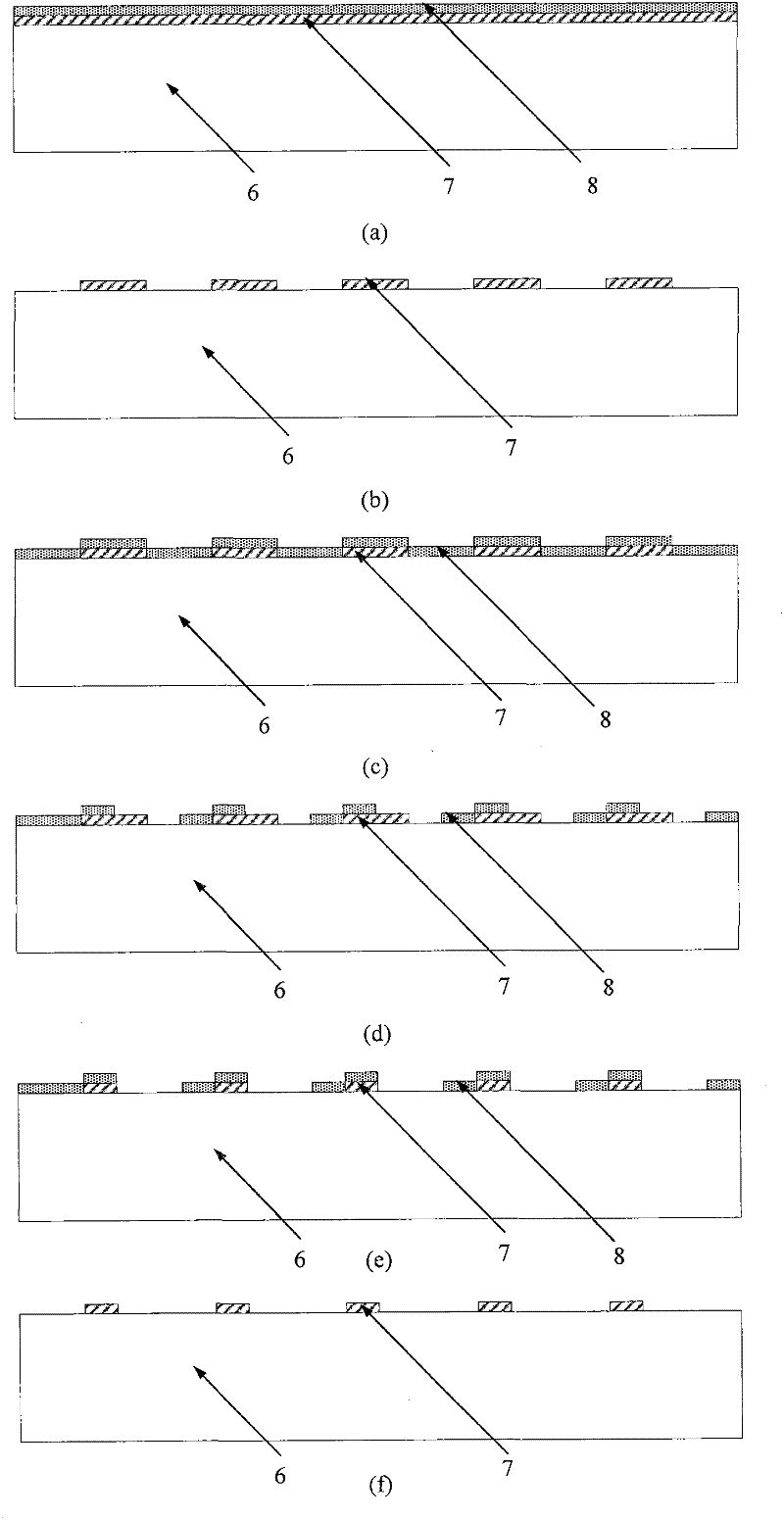

[0032] In the high duty ratio self-supporting nano transmission grating in this embodiment, both ends of the parallel nano transmission grating lines 2 are fixed on the nano transmission grating line fixing structure 3, and the nano transmission grating line fixing structure 3 The intermediate oxide layer 5 is integrated with the nano-transmission grating support structure 1, and the nano-transmission grating grid line 2 forms a structure suspended on the intermediate oxide layer 5 and the nano-transmission grating support structure 1; the gold absorber 4 covers the On the nano transmission grating grid line 2 and the nano transmission grating grid line fixed structure 3; the line width of the grid line structure is 0.5 μm, and the spacing is 0.5 μm; the thickness of the gold absorber 4 is 1 μm.

[0033] The fabrication method of the high-duty ratio self-supporting nano-transmission grating in this embodiment includes two parts: fabrication of a nano-grating mask and fabricatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com