Layer-by-layer assembled microcapsule and its preparation method

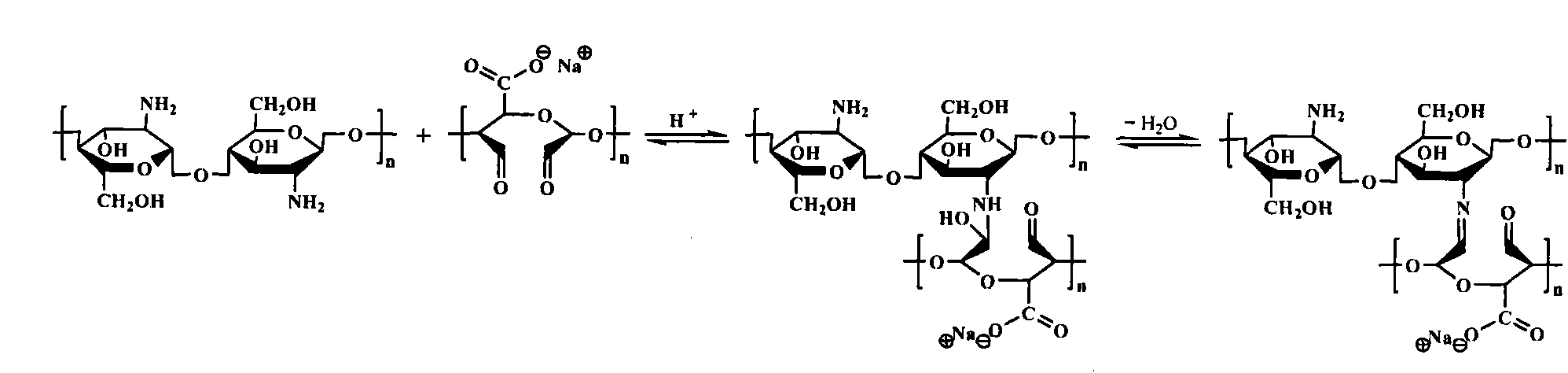

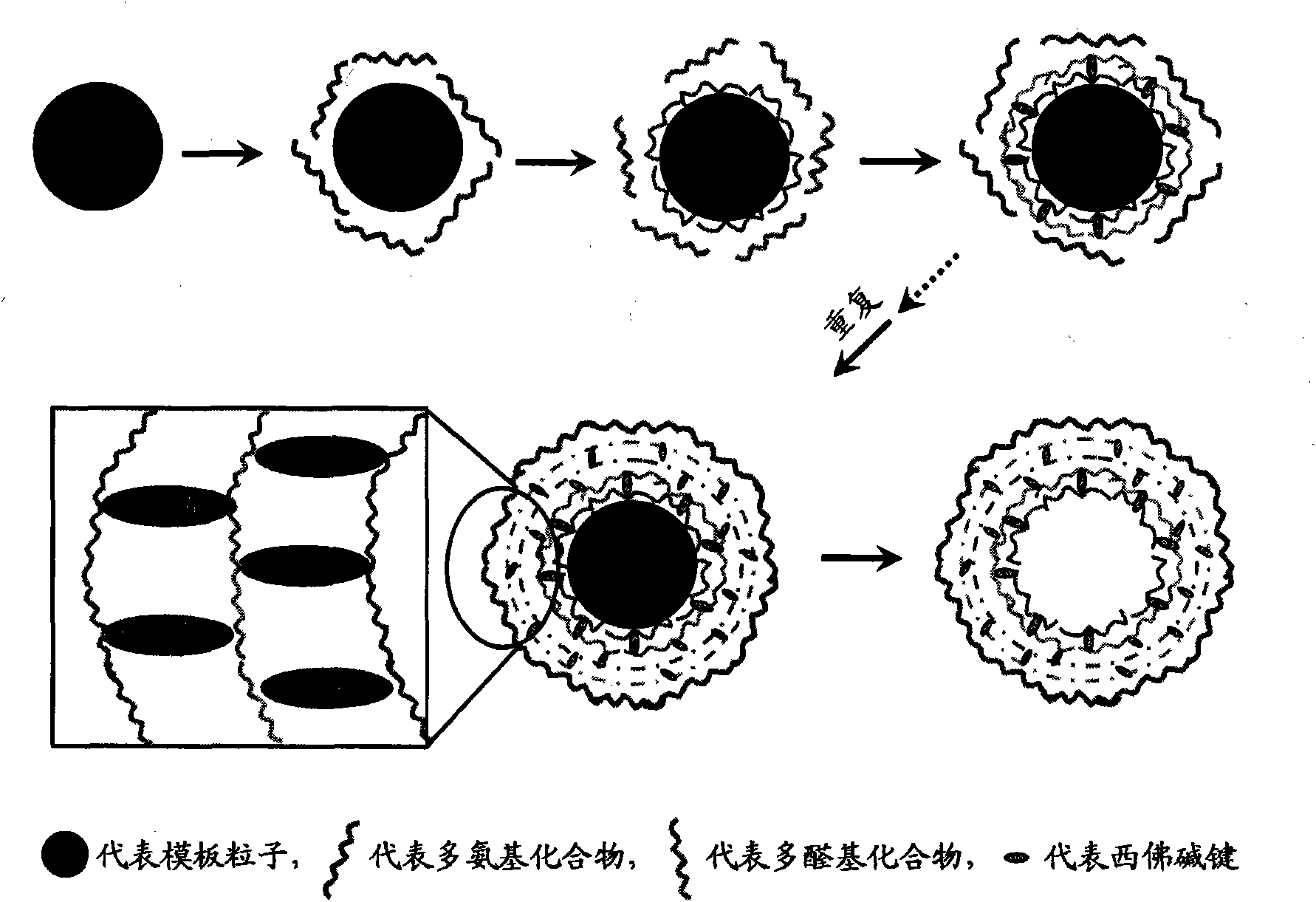

A layer-by-layer assembly and microcapsule technology is applied in the field of layer-by-layer assembly of microcapsules and its preparation, which can solve the problems of easy dissolution, entering the human body, and toxic cross-linking agents, and achieves the effect of good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of oxidized sodium alginate (ADA) with dialdehyde structure

[0034] 5 g of sodium alginate was prepared into a solution with a concentration of 2.5 wt % with distilled water, 5.4 g of sodium periodate was added to the solution, and an appropriate amount of ethylene glycol was added to stop the reaction after 24 hours of reaction in the dark. The solution was mixed with 10 g of sodium chloride, and the product was precipitated with 200 mL of absolute ethanol, filtered with suction and dissolved in deionized water, and precipitated with ethanol again. ADA can be prepared by vacuum drying for 24h.

[0035] (2) Biocompatible microcapsules based on Schiff base bond assembly

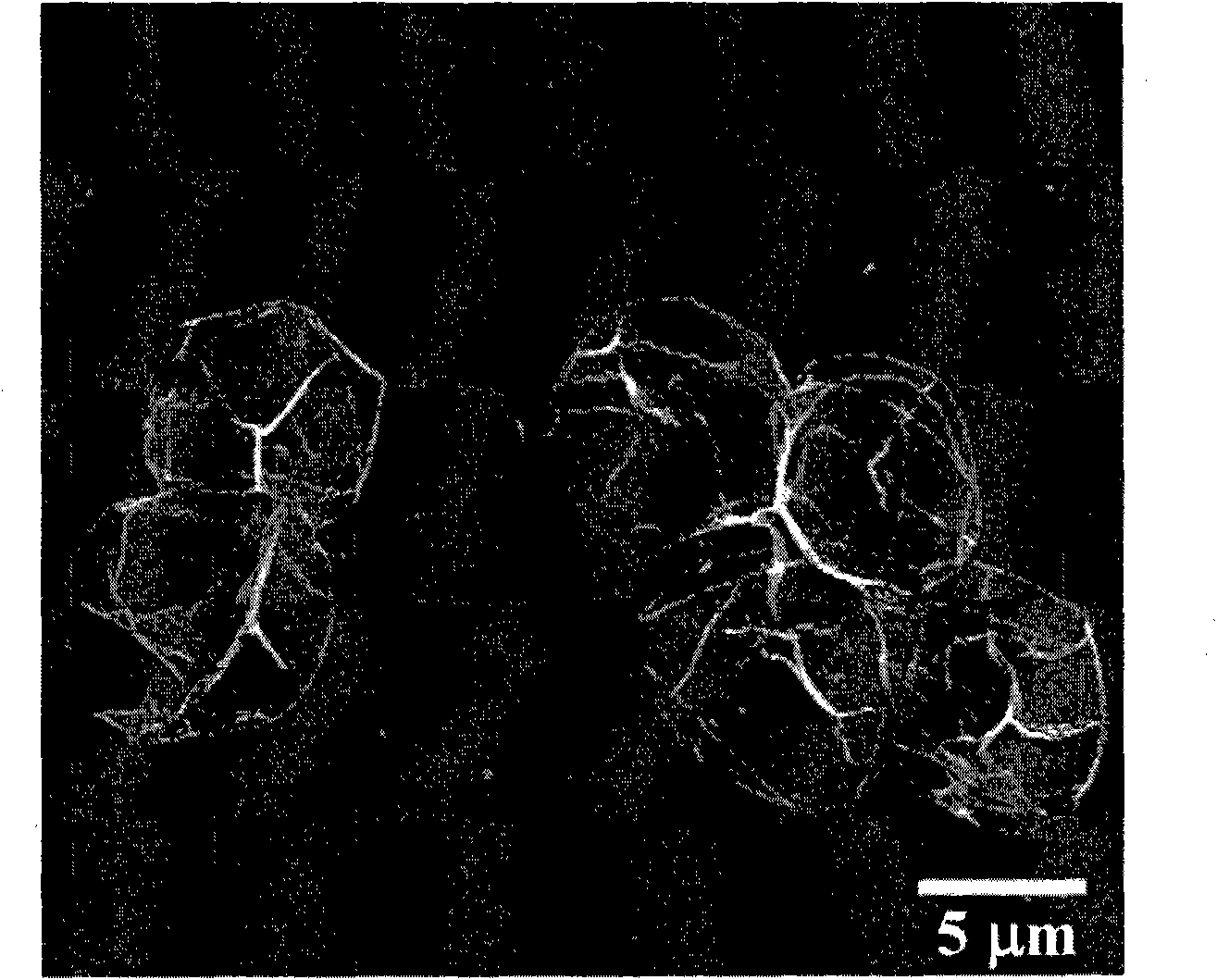

[0036] First, the manganese carbonate particles were dispersed into a 1 mg / mL chitosan (chitosan, CHI) solution containing 0.5 M sodium chloride, and after 30 min of vibration adsorption, centrifuged, washed thoroughly, and then dispersed into a solution containing 0.5 M sodium chlorid...

Embodiment 2

[0039](1) Preparation of dialdehyde cellulose (DAC) with dialdehyde structure

[0040] 5 g of cellulose was prepared into a solution with a concentration of 2.5 wt % with distilled water, 5.4 g of sodium periodate was added to the solution, and an appropriate amount of ethylene glycol was added to stop the reaction after 24 hours of reaction in the dark. The solution was mixed with 10 g of sodium chloride, and the product was precipitated with 200 mL of absolute ethanol, filtered with suction and dissolved in deionized water, and precipitated with ethanol again. The DAC can be prepared by vacuum drying for 24h.

[0041] (2) Biocompatible microcapsules based on Schiff base bond assembly

[0042] First, the polystyrene colloidal particles were dispersed into a 1 mg / mL chitosan (CHI) solution containing 0.5 M sodium chloride, and after 6 h of vibration adsorption, centrifuged, washed thoroughly, and then dispersed into a solution containing 0.5 M chlorine The aldehyde group on ...

Embodiment 3

[0044] (1) Preparation of oxidized starch (dialdehyde starch, DAS) with dialdehyde structure

[0045] 5 g of starch was prepared into a solution with a concentration of 2.5 wt % with distilled water, 5.4 g of sodium periodate was added to the solution, and an appropriate amount of ethylene glycol was added to stop the reaction after 24 hours of reaction in the dark. The solution was mixed with 10 g of sodium chloride, and the product was precipitated with 200 mL of absolute ethanol, filtered with suction and dissolved in deionized water, and precipitated with ethanol again. DAS can be prepared by vacuum drying for 24h.

[0046] (2) Biocompatible microcapsules based on Schiff base bond assembly

[0047] First, the calcium carbonate particles were dispersed in a 5 mg / mL chitosan (CHI) solution containing 0.5 M sodium chloride, and after 30 min of vibration adsorption, centrifuged, washed thoroughly, and then dispersed into a solution containing 0.5 M sodium chloride. The aldeh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com