Method for preparing bio-organic fertilizer by biological fermentation of banana stalk and leaves

A bio-organic fertilizer and bio-fermentation technology is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers. It can solve the problems of low utilization rate of discarded banana stems and leaves, troublesome banana field management, and high cellulose content. Inhibit the spread of soil-borne pathogens, enhance soil air permeability, and stimulate rapid growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

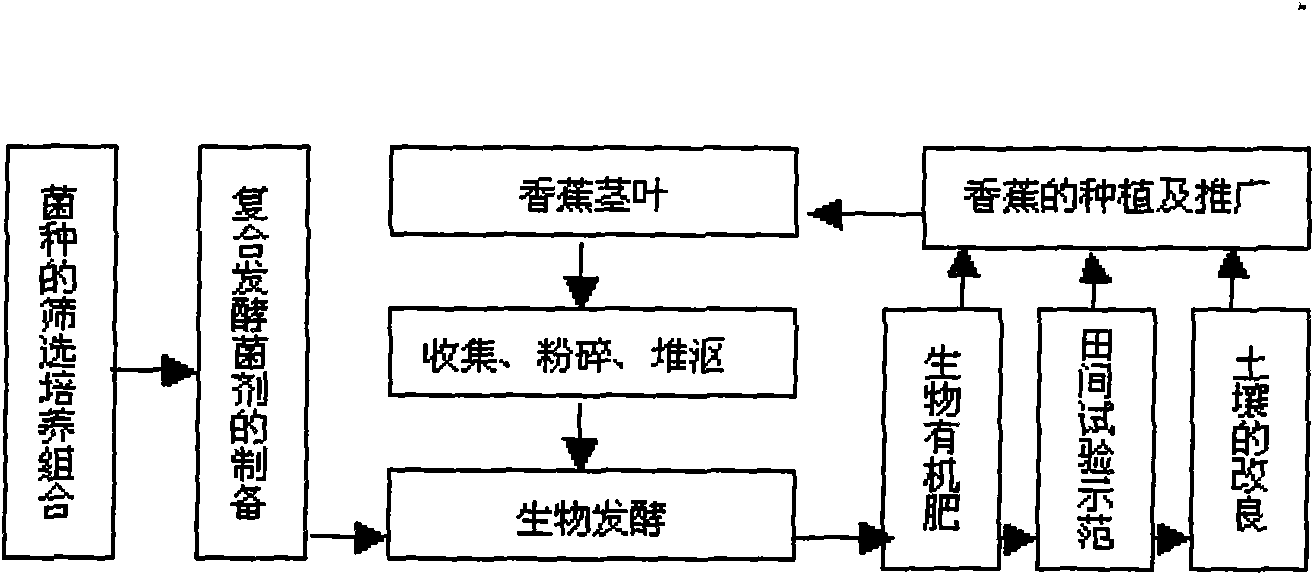

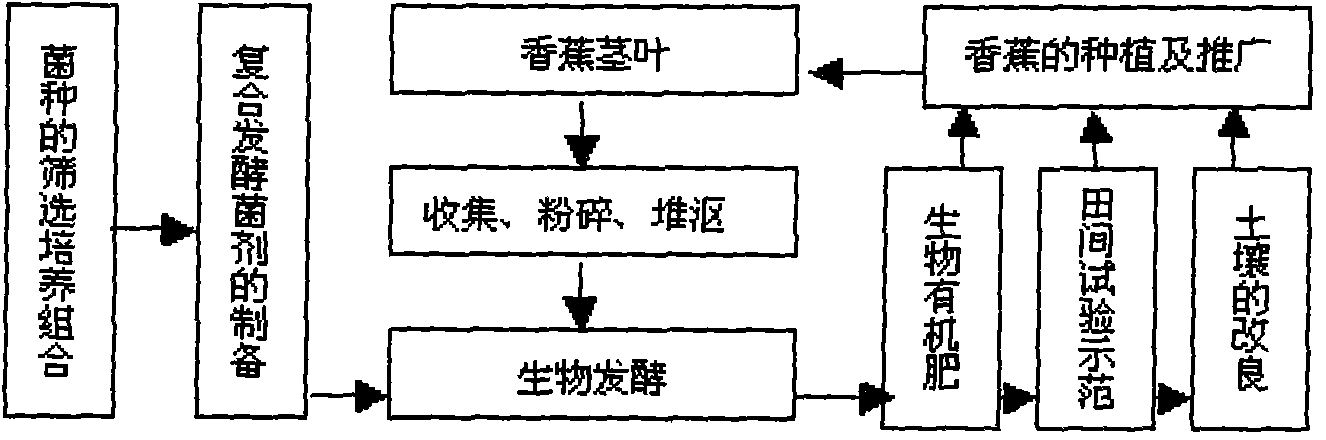

[0016] see figure 1 , a kind of method that utilizes banana stem and leaf to carry out biofermentation to make bio-organic fertilizer, it comprises the steps: (1), cut down the banana stem from the 1.5m place of the bottom of the banana stem, and the uncut part is for sucking teeth to grow; 2), split the felled banana stalks in half axially, let it dry naturally for 5 days, until the water content is about 70%; (3), cut and pulverize the banana stalks with 70% water content with a pulverizer or a hay cutter to a short section with a length of 2cm; (4), add 5% chicken manure and 0.1% biological fermentation agent to the above-mentioned short section, mix and stir to obtain solid mixed raw materials, and the described biological fermentation agent is selected from high-temperature bacteria, Fungus or actinomycetes; (5), add water to the solid mixed raw material of step (4) and stir, the content of water is 60%, obtain the liquid mixed raw material; (6), stack the above-mentioned...

Embodiment 2

[0018] see figure 1 , a kind of method that utilizes banana stem and leaf to carry out biofermentation to make bio-organic fertilizer, it comprises the steps: (1), cut down the banana stem from the 1.5m place of the bottom of the banana stem, and the uncut part is for sucking teeth to grow; 2), split the felled banana stalks in half axially, let it dry naturally for 7 days, until the water content is about 70%; (3), cut and pulverize the banana stalks with 70% water content with a pulverizer or a hay cutter to a short section with a length of 3 cm; (4), add 5% chicken manure and 0.1%-0.2% biological fermentation agent to the above-mentioned short section, mix and stir to obtain solid mixed raw materials, and the biological fermentation agent is selected High-temperature bacteria, fungi or actinomycetes; (5), add water to the solid mixed raw material of step (4) and stir, and the content of water is 70%, to obtain the liquid mixed raw material; (6), stack the above-mentioned li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com