Conductive PC/ABS composite material and its preparation method

A composite material and ABS resin technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of insufficient physical properties of conductive plastics, achieve stable microstructure, improve blending effect, and improve toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

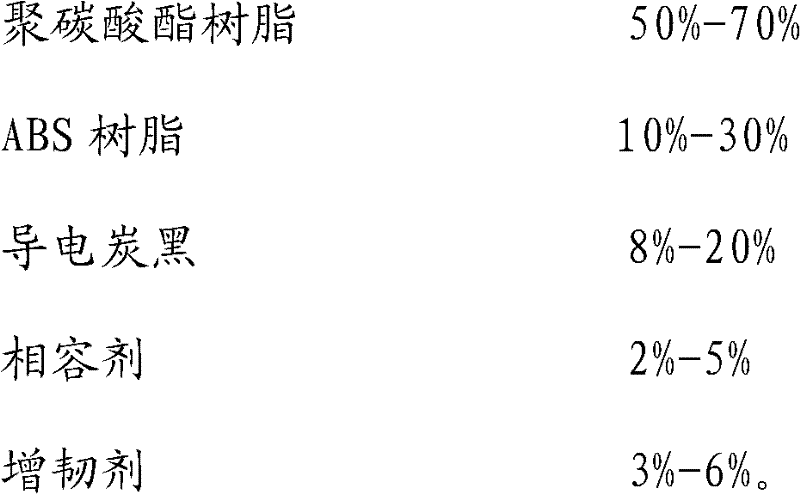

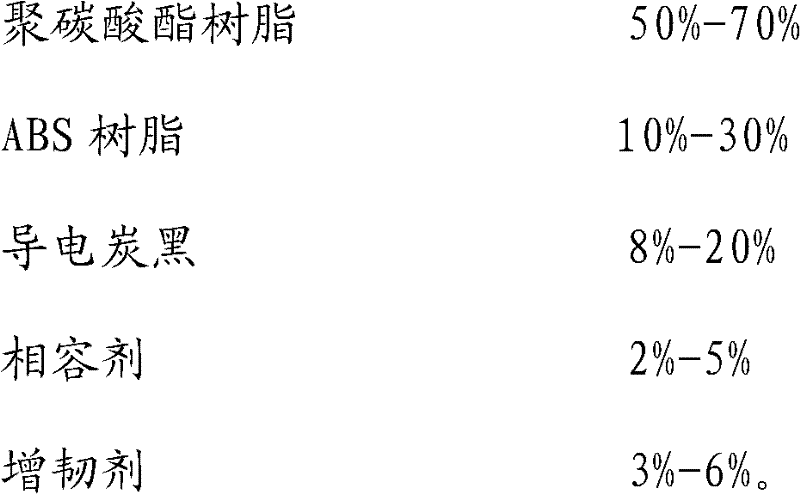

[0025] The conductive PC / ABS composite material of this embodiment comprises the following components by weight percentage:

[0026] 70% polycarbonate resin, 14% ABS resin, 5% ABS grafted maleic anhydride (compatibilizer), 3% copolymer of methacrylate and acrylate (toughener), 8% conductive carbon black.

[0027] Its preparation method is as follows:

[0028] Step 1. Weigh each component according to the above weight percentage, put the weighed polycarbonate resin and ABS resin into a drying box respectively, and dry the polycarbonate resin at 100°C for 3 hours; ABS resin at 80 At ℃, dry for 2h;

[0029] Step 2, put the dried polycarbonate resin, ABS resin and ABS grafted maleic anhydride, methacrylate and acrylate copolymer and conductive carbon black into a high-speed mixer and stir for 3 minutes until uniformly mixed. form a mixture;

[0030] Step 3: Add the mixed material into the hopper of the twin-screw extruder, carry out the melting reaction, extrude and granulate, ...

Embodiment 2

[0032] The conductive PC / ABS composite material of this embodiment comprises the following components by weight percentage:

[0033] Polycarbonate resin 70%, ABS resin 10%, ethylene-butyl acrylate-glycidyl methacrylate (compatibilizer) 2%, methyl methacrylate, butadiene and styrene terpolymer (increase toughening agent) 3%, conductive carbon black 15%.

[0034] Its preparation method is as follows:

[0035] Step 1. Weigh each component according to the above weight percentage, put the weighed polycarbonate resin and ABS resin into a drying box respectively, and dry the polycarbonate resin at 120°C for 2.5 hours; ABS resin at 90°C ℃, dry for 1.5h;

[0036] Step 2, put polycarbonate resin, ABS resin and ethylene-butyl acrylate-glycidyl methacrylate, methyl methacrylate, butadiene and styrene terpolymer and conductive carbon black after drying treatment Stir in a high-speed mixer for 3 minutes until the mixture is evenly mixed to form a mixed material;

[0037] Step 3: Add th...

Embodiment 3

[0039] The conductive PC / ABS composite material of this embodiment comprises the following components by weight percentage:

[0040] Polycarbonate resin 50%, ABS resin 30%, polypropylene grafted maleic anhydride (compatibilizer) 3%, methacrylate and acrylate copolymer (toughener) 4%, conductive carbon black 13% .

[0041] Its preparation method is as follows:

[0042] Step 1. Weigh each component according to the above weight percentage, put the weighed polycarbonate resin and ABS resin into a drying oven respectively, and dry the polycarbonate resin at 110°C for 3 hours; ABS resin at 85 At ℃, dry for 2h;

[0043] Step 2. Put the dried polycarbonate resin, ABS resin, polypropylene grafted maleic anhydride, methacrylate and acrylate copolymer, and conductive carbon black into a high-speed mixer and stir for 3 minutes until evenly mixed , forming a mixed material;

[0044]Step 3: Add the mixed material into the hopper of the twin-screw extruder, carry out the melting reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com