Special type pattern machine for sewing in large area

A pattern machine and large-area technology, applied in the field of sewing machines, can solve the problems of single pattern, small sewing range, elongation, etc., and achieve the effect of various sewing patterns, wide sewing range and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

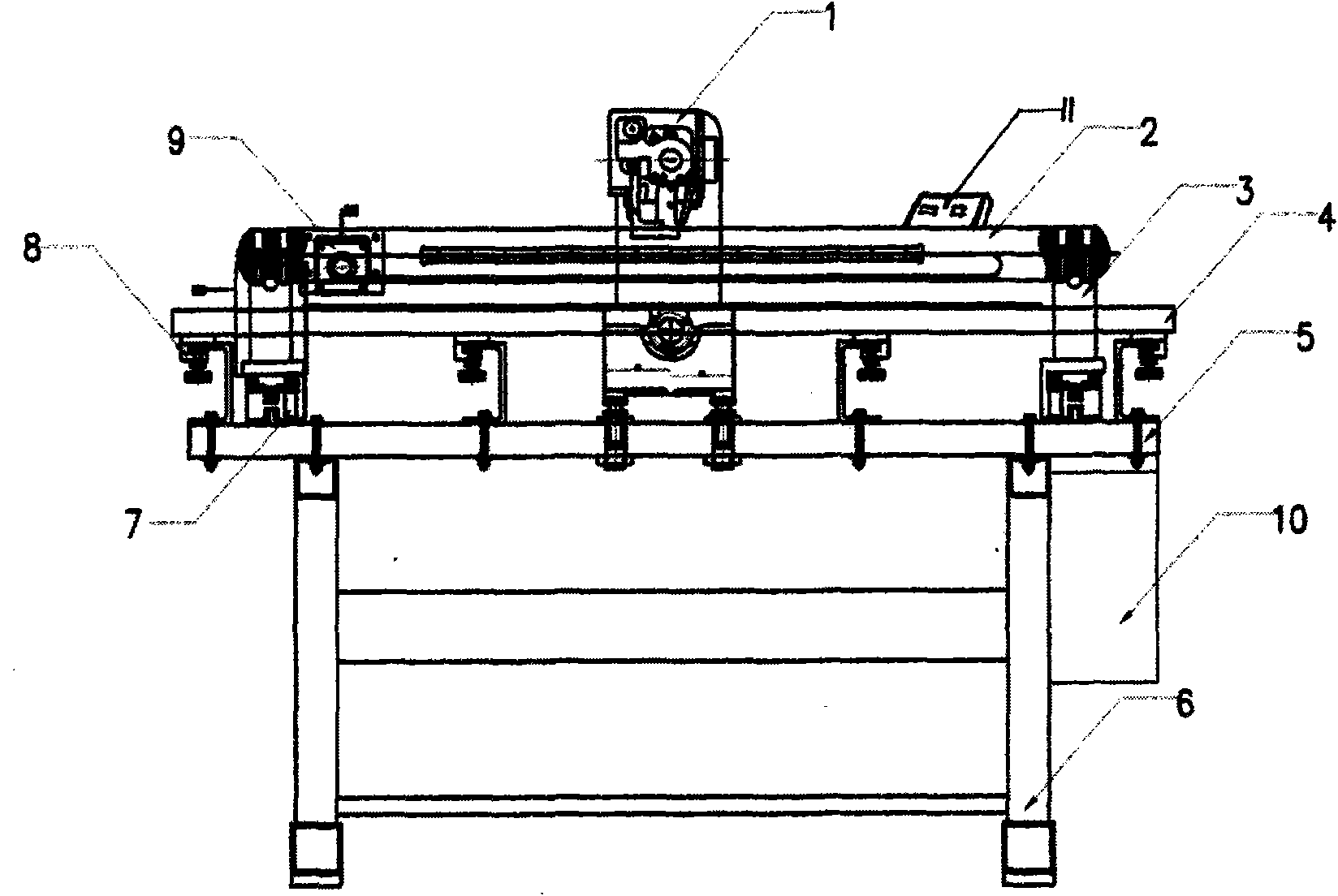

[0008] according to figure 1 , as shown, the present invention provides a large-area sewing special model pattern machine, which consists of 1 machine head, 2 guide rails, 3 sliding brackets, 4 platens, 5 supporting platens, 6 frames, 7Y guide rails, 8 It is composed of platen fixing frame, 9X-direction driving motor, 10 electric control boxes, and 11 digital display (touch screen). The electric control box 10 is arranged on the right side of the frame 6, the supporting platen 5 is fixed on the frame 6, and the platen fixing frame 8 is placed on the supporting platen 5, a total of 4, and the platen fixing frame 8 is provided with Platen 4, fixed with fasteners, Y-guiding rail 7 is arranged on the support platen 5, one on the left and right, sliding bracket 3 is located on Y-guiding rail 7, guide rail 2 is arranged on the sliding bracket 3, X-direction drive motor 9 is fixed on one end of the guide rail 2, the machine head 1 slides on the guide rail 2, and the digital display ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com