Solar heat transfer unit

A solar energy and heat transfer medium technology, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of difficult practical operation, difficult to guarantee safety, high system cost, no leakage danger, simple driving, The effect of high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

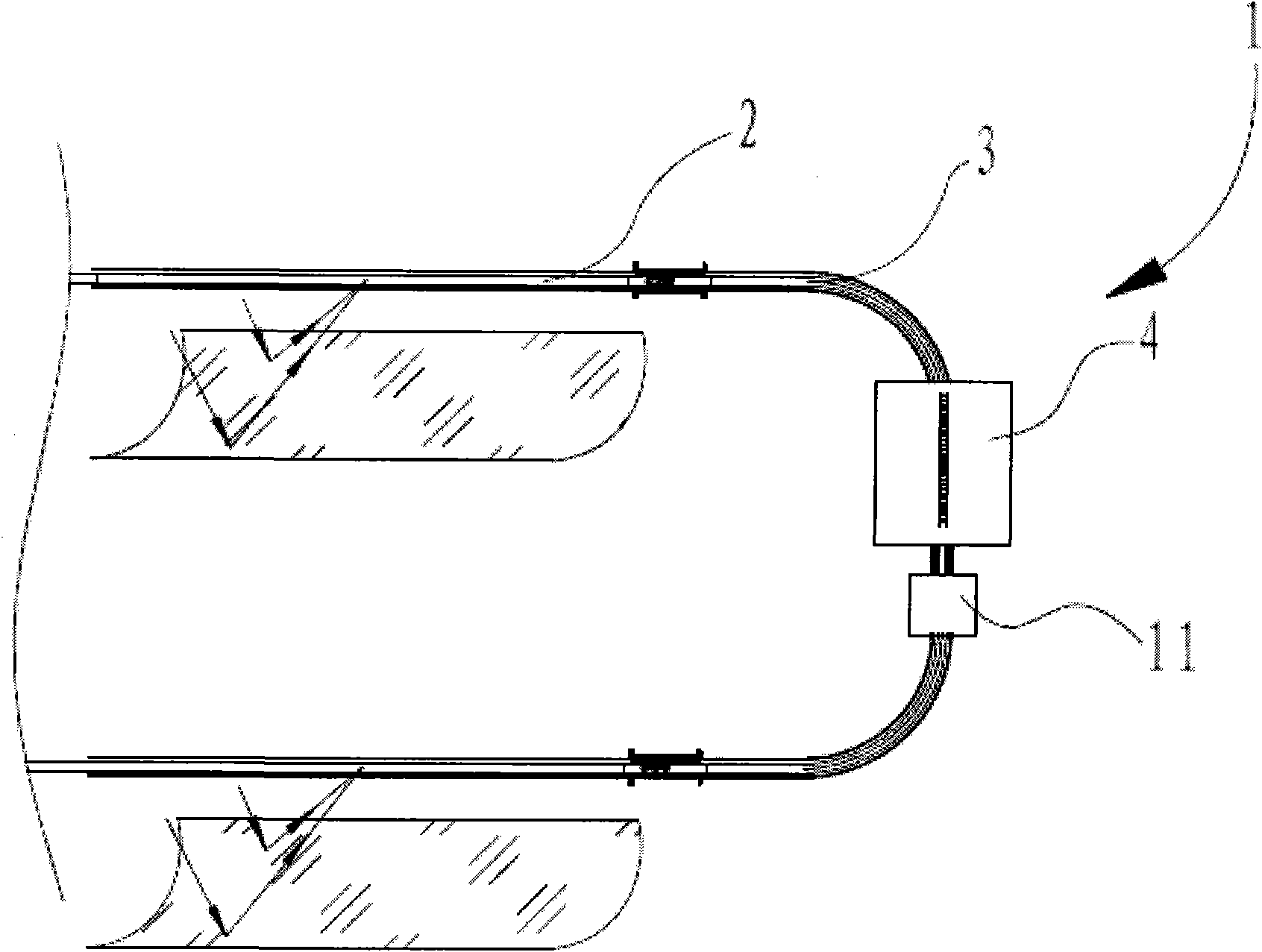

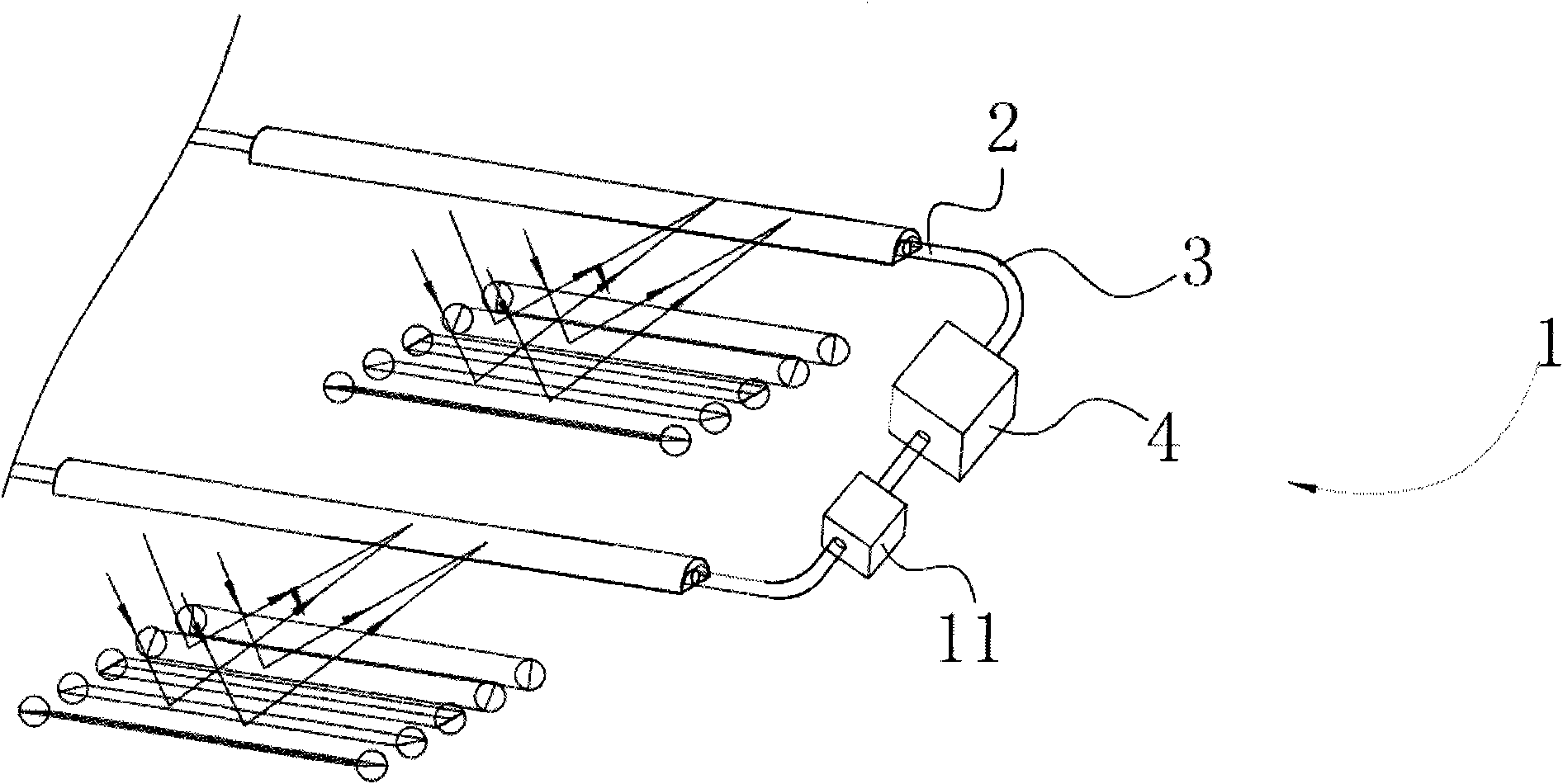

[0051] Figure 1a and Figure 1bIt is a schematic layout diagram of a solar heat transfer device 1 according to an embodiment of the present invention. The heat transfer device 1 includes a heat receiving area 2 , a turning area 3 and a heat releasing area 4 , where the positions corresponding to the heat receiving area 2 are respectively the telephoto line positions of the solar parabolic reflector trough or the Fresnel reflector array. The heated area 2 receives sunlight reflected from the reflector. The solar heat transfer device 1 has a ring structure as a whole, wherein the heat receiving area 2 is in the shape of a long straight line, and its length is, for example, at least 10 meters.

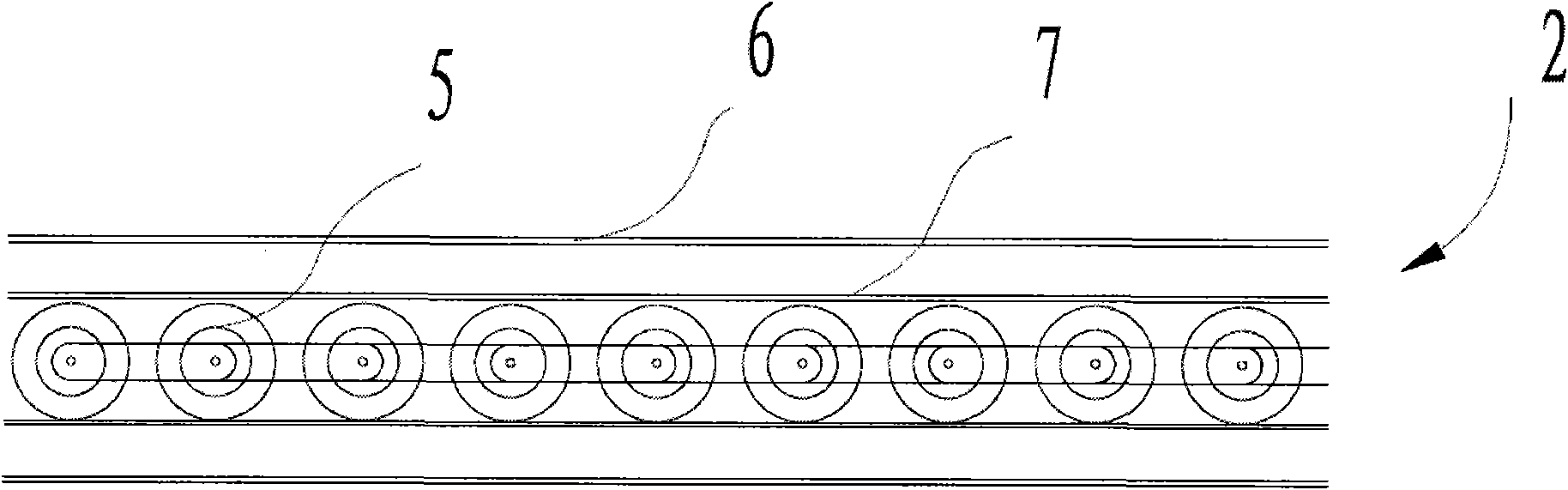

[0052] figure 2 It is a schematic diagram of the heat receiving area 2 in the heat transfer device 1 . The heated area 2 receives the long focal line position of the solar reflection trough, receives the energy from the sun, and its whole is linear. The heated zone 2 comprises an ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com