Method for detecting passivant in transformer oil by high efficiency liquid chromatography

A technology of high-performance liquid chromatography and detection method, which is applied in the field of high-performance liquid chromatography detection of passivating agents in transformer oil, and can solve the problems of not establishing insulating oil and not knowing the change situation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

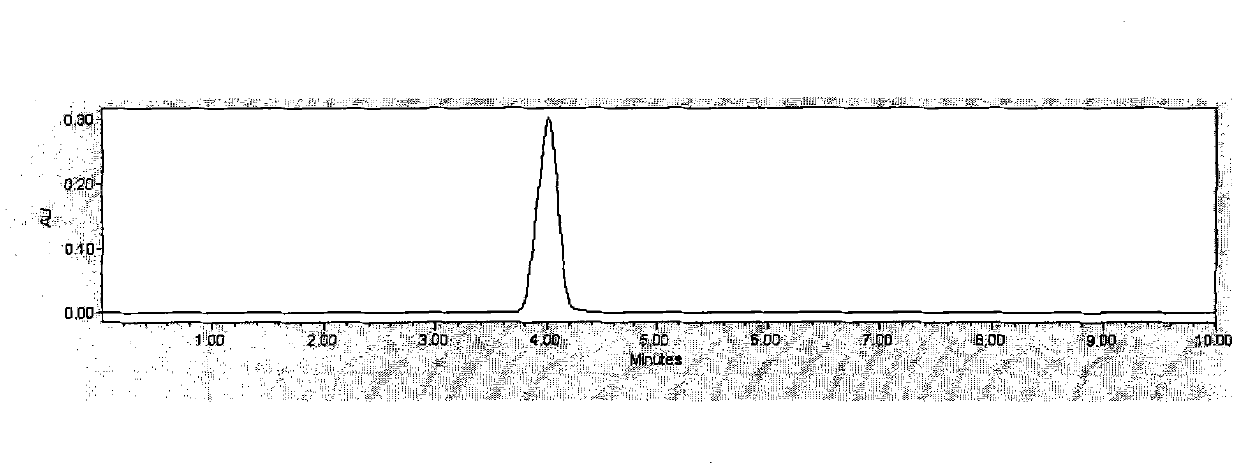

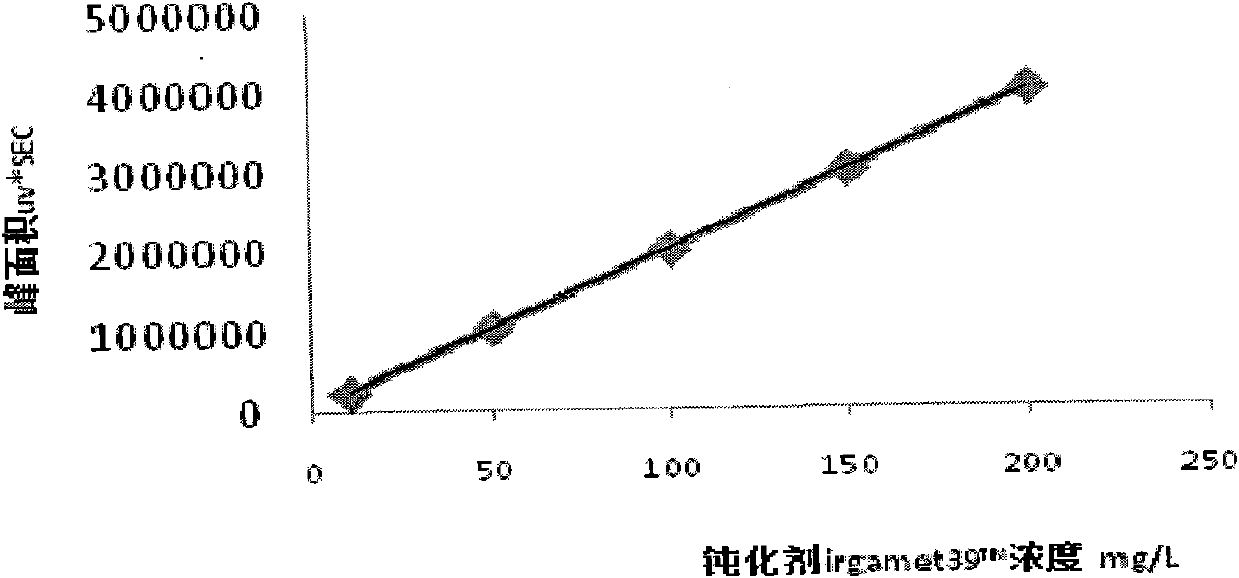

Embodiment 1

[0012] Use waters high-performance liquid chromatography to detect the Irgamet39-containing TM Transformer oil samples with passivating agent concentrations of 10, 50, 100, 150, and 200 mg / L were tested, and Symmetry C was selected 8 Chromatographic column, the length of the chromatographic column is 250mm, the column diameter is 4.6mm, the filler is silicon, the particle diameter is 5um, and the pore diameter is The injection volume was 10 μl, the flow rate was 1 ml / min, the column temperature was 35° C., the mobile phase was aqueous methanol (the volume ratio of methanol to water was 70:30), and the detector was Waters CapLC 2487 UV-visible dual-wavelength detector. Test results such as figure 1 As shown, there is a passivating agent (Irgamet 39) detection peak at 4.05min. For a typical chromatogram see figure 1 . Using the standard curve external standard method ( figure 2 ) for quantitative detection. By applying this method, the passivator Irgamet39 in transformer...

Embodiment 2

[0014] Use waters high performance liquid chromatography to contain Irgamet39 TM The transformer oil of the passivating agent is tested, and the Symmetry C18 chromatographic column is selected. The length of the chromatographic column is 150mm, the column diameter is 4.6mm, the filler is silicon, the particle size is 5um, and the pore size is The injection volume was 20 μl, the flow rate was 1 ml / min, the column temperature was 30° C., the mobile phase was aqueous methanol (the volume ratio of methanol and water was 60:40), and the detector was Waters CapLC2487 UV-visible dual-wavelength detector.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Column diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com