Bifocus micro lens with aspheric surface and adjustable focal length

An aspheric, bifocal technology, applied in the direction of lens, nonlinear optics, optics, etc., can solve the problems that it is difficult to realize the surface structure of aspheric microlens, the structure of microlens array, and the surface shape cannot be precisely controlled. Easy to design and process, easy to realize the array structure, easy to control the effect precisely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

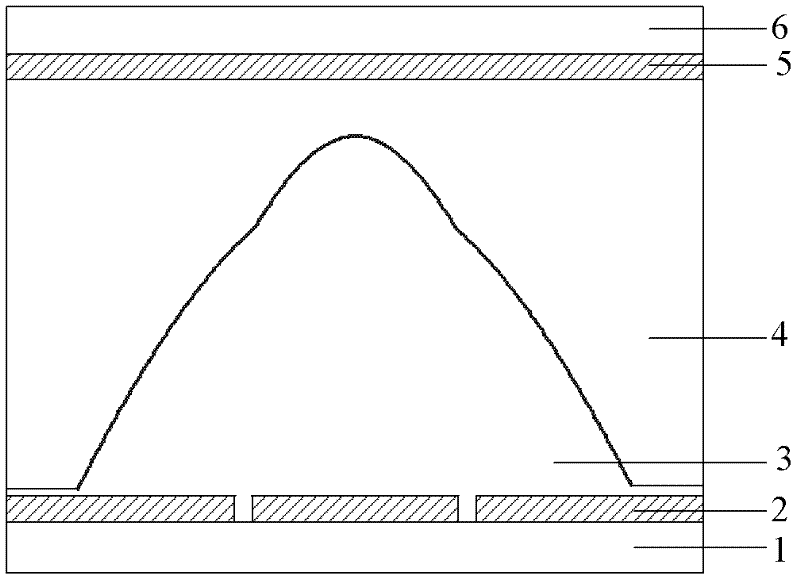

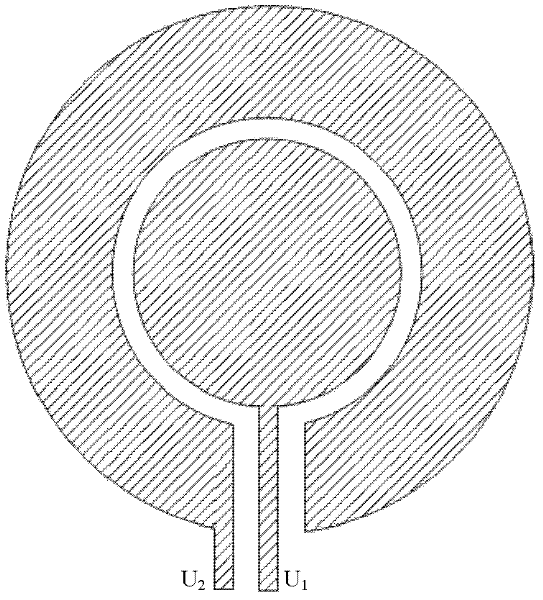

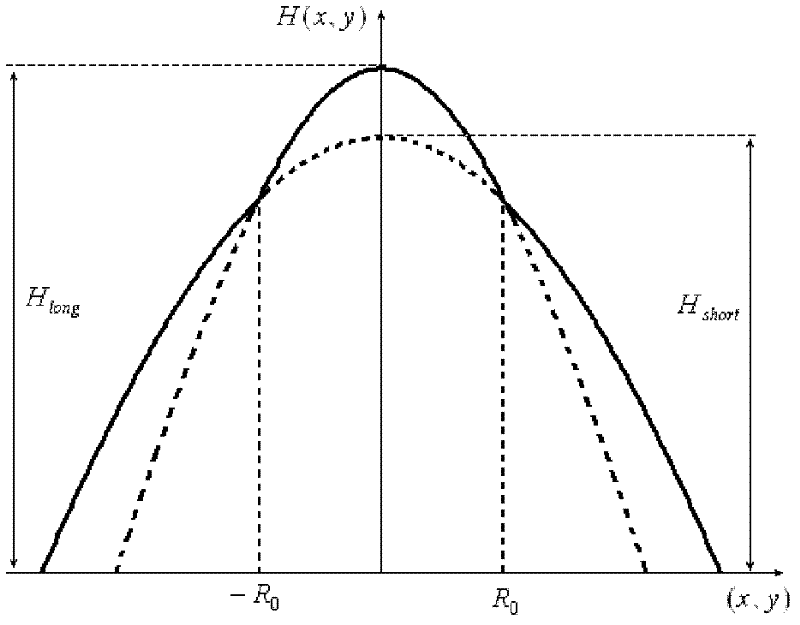

[0019] A bifocal aspheric microlens with adjustable focal length, such as figure 1 As shown, it includes a lower transparent glass substrate 1 , a lower ITO electrode 2 , a liquid crystal layer 3 , a liquid crystal sealing layer 4 , an upper ITO electrode 5 and an upper transparent glass substrate 6 . The upper ITO electrode 5 is located between the upper transparent glass substrate 6 and the liquid crystal sealing layer 4 , and the lower ITO electrode 2 is located between the lower transparent glass substrate 1 and the liquid crystal layer 3 . The surface of the liquid crystal sealing layer 4 in contact with the liquid crystal layer 3 is a concave aspheric shape, and the concave aspheric shape is as follows image 3As shown, it is formed by the intersection of rotationally symmetric surface 1 with higher height but smaller radius of curvature and rotationally symmetric surface 2 with lower height but larger radius of curvature. The material of the liquid crystal sealing laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com