Method for the formation of multi-layer paint films

A paint film and varnish technology, applied in the field of forming multi-layer paint films, can solve the problems of unclear obtaining method, unable to obtain paint film value, unable to obtain chipping resistance, etc., and achieve excellent chipping resistance and good paint film. effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1-10

[0097] Water-based first colored primers A-1 to A-5 and water-based second colored primers B-1 to B-5 Example

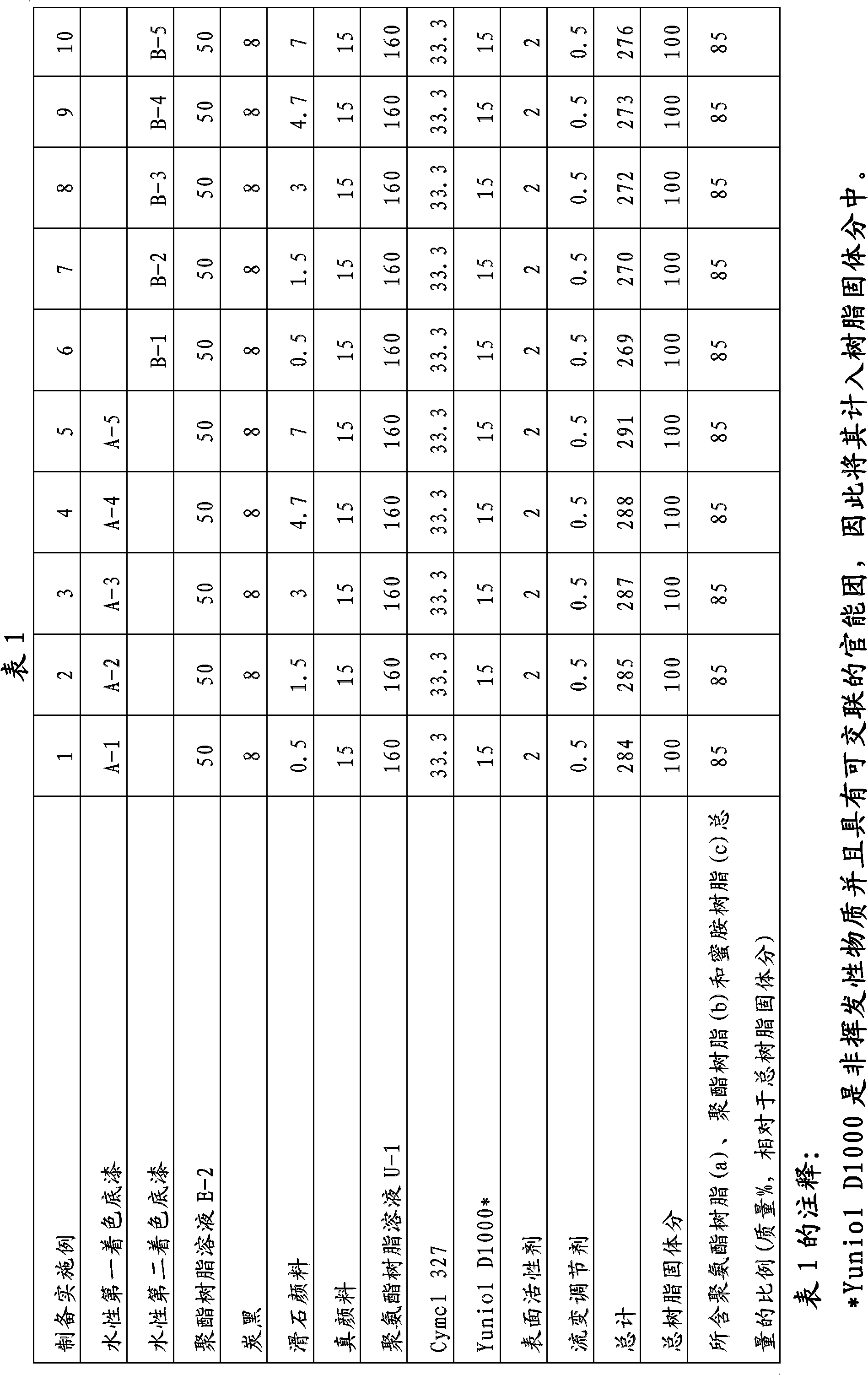

[0098] Water-based first colored primers A-1 to A-5 and water-based second colored primers B-1 to B-5 were prepared according to the mixing ratio shown in Table 1. In Table 1, the unit of the amount of each component is parts by mass.

[0099]The first water-based colored primer and the second aqueous colored primer are prepared by the mixing ratio shown in Table 1 by the following method: carbon black (trade name MA-100, produced by Mitsubishi Kagaku), talcum pigment (trade name Talc LMS-200, produced by Fuji Talc Kogyo) and true pigment (trade name barium sulfate B34, produced by Sakai Kagaku) were added to polyester resin emulsion E-2, and dispersed in a disperser, and then polyurethane resin solution U was added -1. Melamine resin (trade name Cymel 327, methylated melamine resin produced by Cytec Co., 90% non-volatile matter), polypropylene glycol (trade na...

preparation Embodiment 11

[0102] The preparation embodiment of two-liquid urethane type paint C-1

[0103] Hydroxyl-containing acrylic resin solution R-1 (70 parts), 1.3 parts of ultraviolet absorber, Tinuvin400 (trade name, produced by Ciba Specialty Chemicals Co.), 0.7 part of light stabilizer, Tinuvin292 (trade name, produced by Ciba Specialty Produced by Chemical Co.), 0.2 parts of surface conditioner, BYK-300 (trade name, produced by BYK Chemie Co.), 5 parts of diethylene glycol monobutyl ether, 12.8 parts of n-butyl acetate, and 10 parts of aromatic naphtha Oil Solvesso 100 (trade name, produced by Esso Co.) was sequentially introduced into the dissolver and mixed therein until the system became uniform. Then 33.3 parts of aliphatic polyisocyanate solution Basonat HI-172S (trade name, produced by BASF Co., 72% solution of HDI-based isocyanate type trimer) was added to obtain two-liquid urethane type paint C-1.

Embodiment 1-5

[0105] Cationic electrodeposition paint V-50 (trade name, produced by Nippon Paint Co.) was electrostatically deposited in such a manner as to provide a cured film thickness of about 20 μm on the alloyed hot-dip galvanized steel sheet treated with zinc phosphate chemical forming, and then Heat to 160°C for 30 minutes and cure.

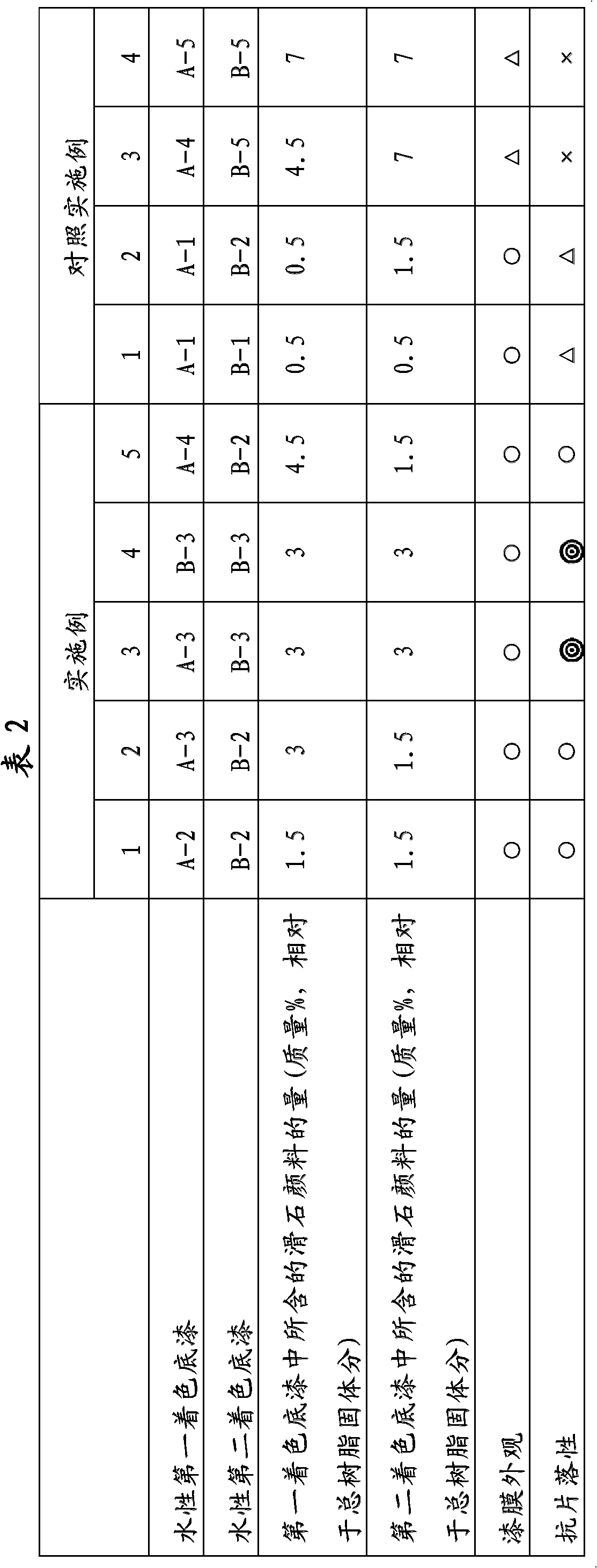

[0106] The water-based first colored primer shown in Table 2 was applied on the cured paint film of the electrodeposition paint using a rotary cup type electrostatic coater so that the thickness of the cured film was 7-12 μm to form the first colored primer film, after standing in the paint booth for 5 minutes, the water-based paint shown in Table 2 was applied on the first pigmented primer film using a rotary cup type electrostatic coater in such a way that the cured film thickness was 5-10 μm. A second colored primer and forms a second colored primer film. It was left to stand in the spray booth for 5 minutes, and then heated to 80° C. for 3 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Glass transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap