Seawater flue gas desulphurization (FGD) system applying boiler blowdown water

A boiler blowdown and desulfurization system technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve problems such as unfavorable flue gas evacuation, low flue gas temperature, equipment corrosion, etc., and achieve the ideal of water quality recovery and improvement. Desulfurization efficiency and corrosion mitigation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

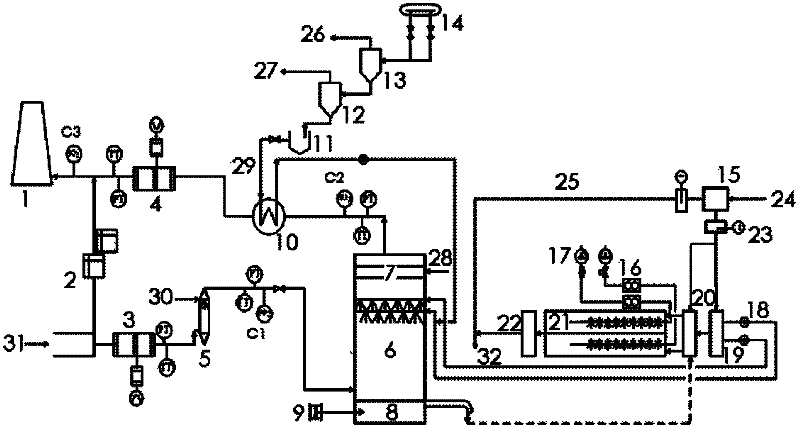

[0026] refer to figure 1 As shown, the equipment connection method in the flue gas seawater desulfurization system using boiler blowdown water is as follows:

[0027] The FGD inlet baffle 3 is connected to the bottom of the precooler 5, the top of the precooler 5 is connected to the bottom of the absorption tower 6, and the top of the absorption tower 6 is connected to the shell-side inlet port of the heat exchanger 10 for heat exchange. The shell-side outlet end of the device 10 communicates with the inlet end of the FGD outlet baffle 4 , and the outlet end of the FGD outlet baffle 4 is connected with the wet chimney 1 .

[0028] The tube-side inlet port of the heat exchanger 10 communicates with the sedimentation tank 11 equipped with boiler blowdown water, and the tube-side outlet port of the heat exchanger 10 communicates with the main pipe at the spray inlet end of the absorption tower 6, which collects Boiler blowdown water from the outlet end of the tube side of the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com