Overlaying equipment of drilling tool for petroleum extraction

A drilling tool and oil technology, which is applied in the field of surface treatment equipment for pipes to achieve the effects of increasing hardness, increasing melting depth and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

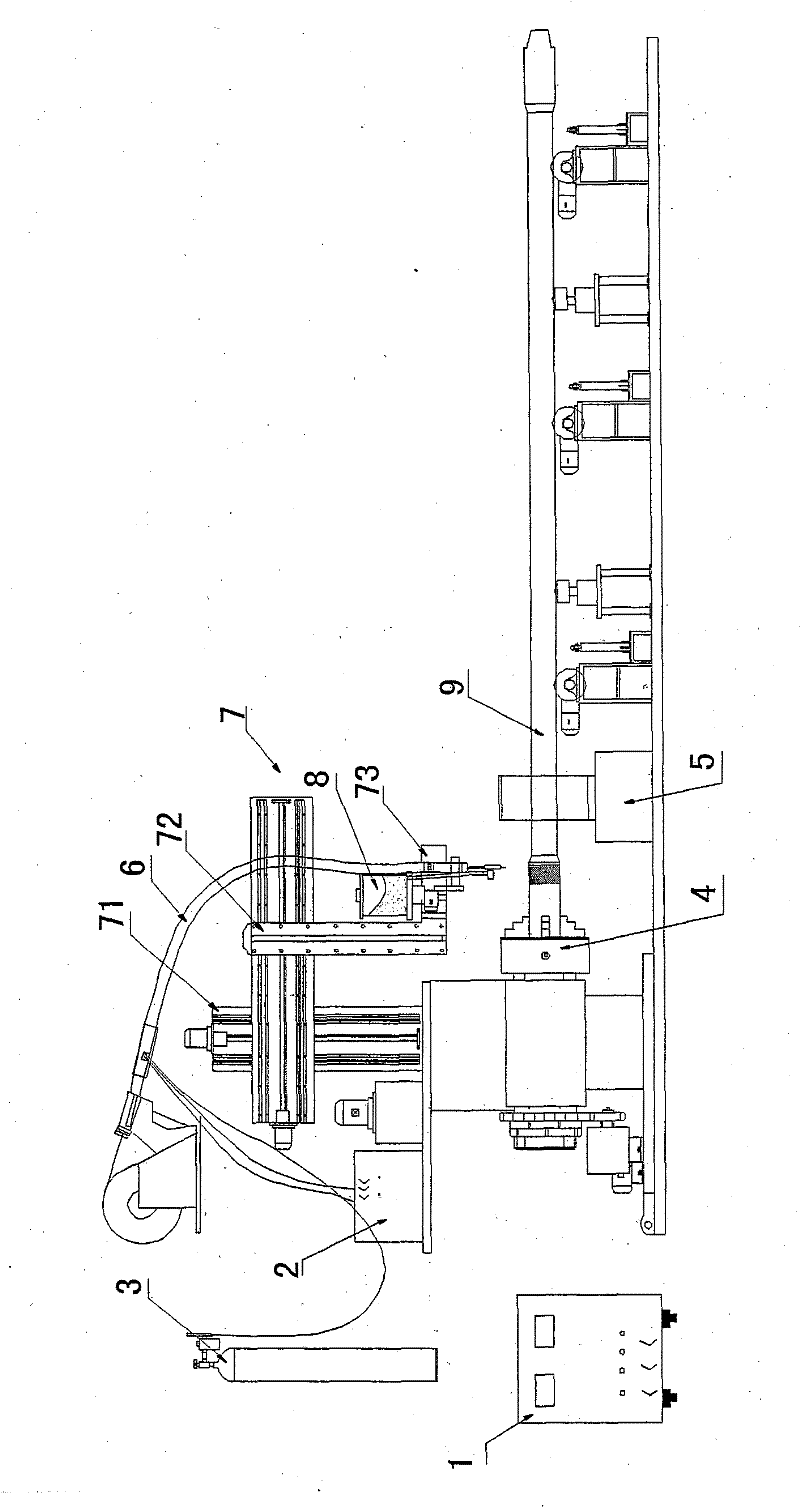

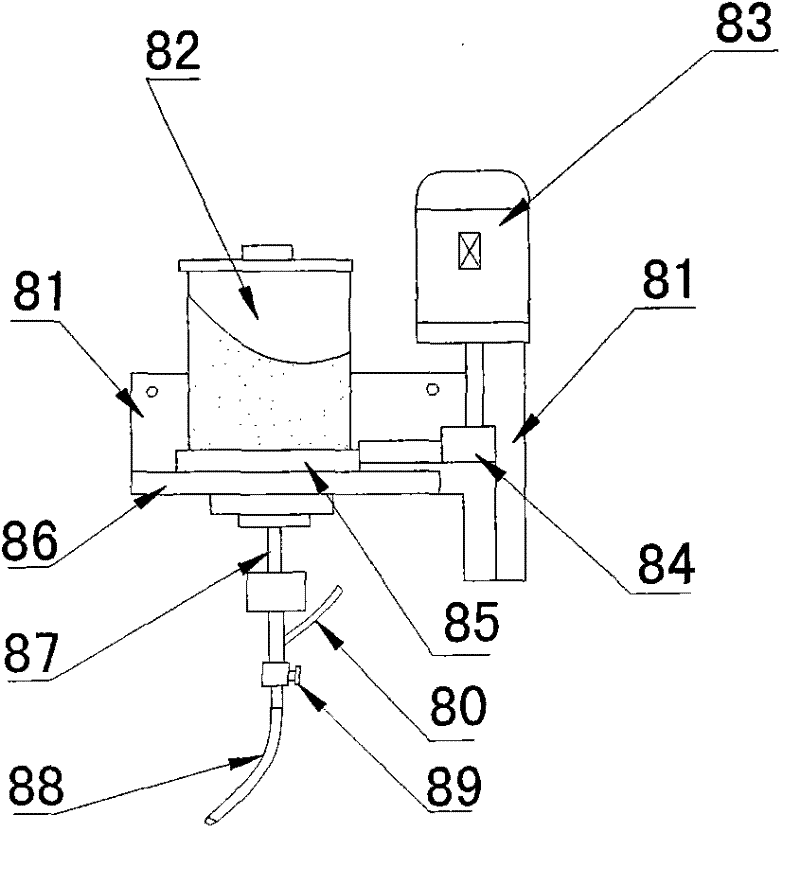

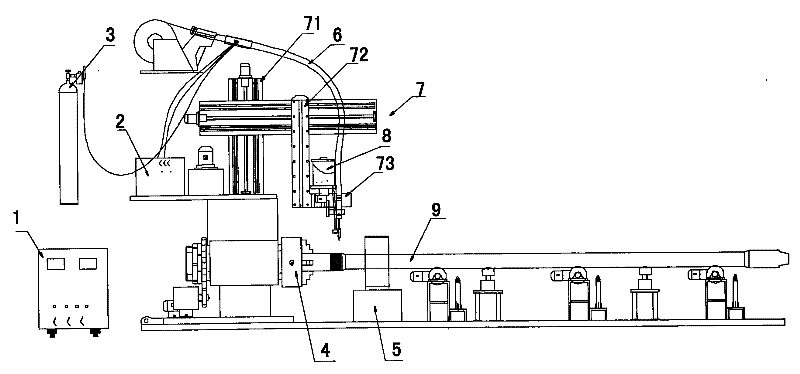

[0014] see figure 1 , figure 2 , the surfacing welding equipment of drilling tool for petroleum exploitation of the present invention comprises automatic control carbon dioxide welding machine, and this automatic control carbon dioxide welding machine comprises gas-shielded welding machine 1, cooling water supply system 2, carbon dioxide protective gas supply system 3, workpiece clamping And feeding system 4, intermediate frequency heating system 5, water-cooled welding torch 6, water-cooled welding torch clamping control mechanism 7 and powder spraying mechanism 8. Wherein the water-cooled torch clamping control mechanism 7 comprises a cross middle plate 71, a cross moving plate 72 and a welding torch adjusting plate 73, the cross moving plate 72 is installed on the cross middle plate 71 and can move laterally along the cross middle plate 71, and the welding torch adjusting plate 73 is installed It can move vertically along the cross moving plate 72 on the cross moving plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com