An automatic assembly and welding device for thin-walled T-profiles

An automatic assembly and welding device technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of low production efficiency and large man-hour consumption, so as to improve production efficiency, avoid manual operation, and reduce manual labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

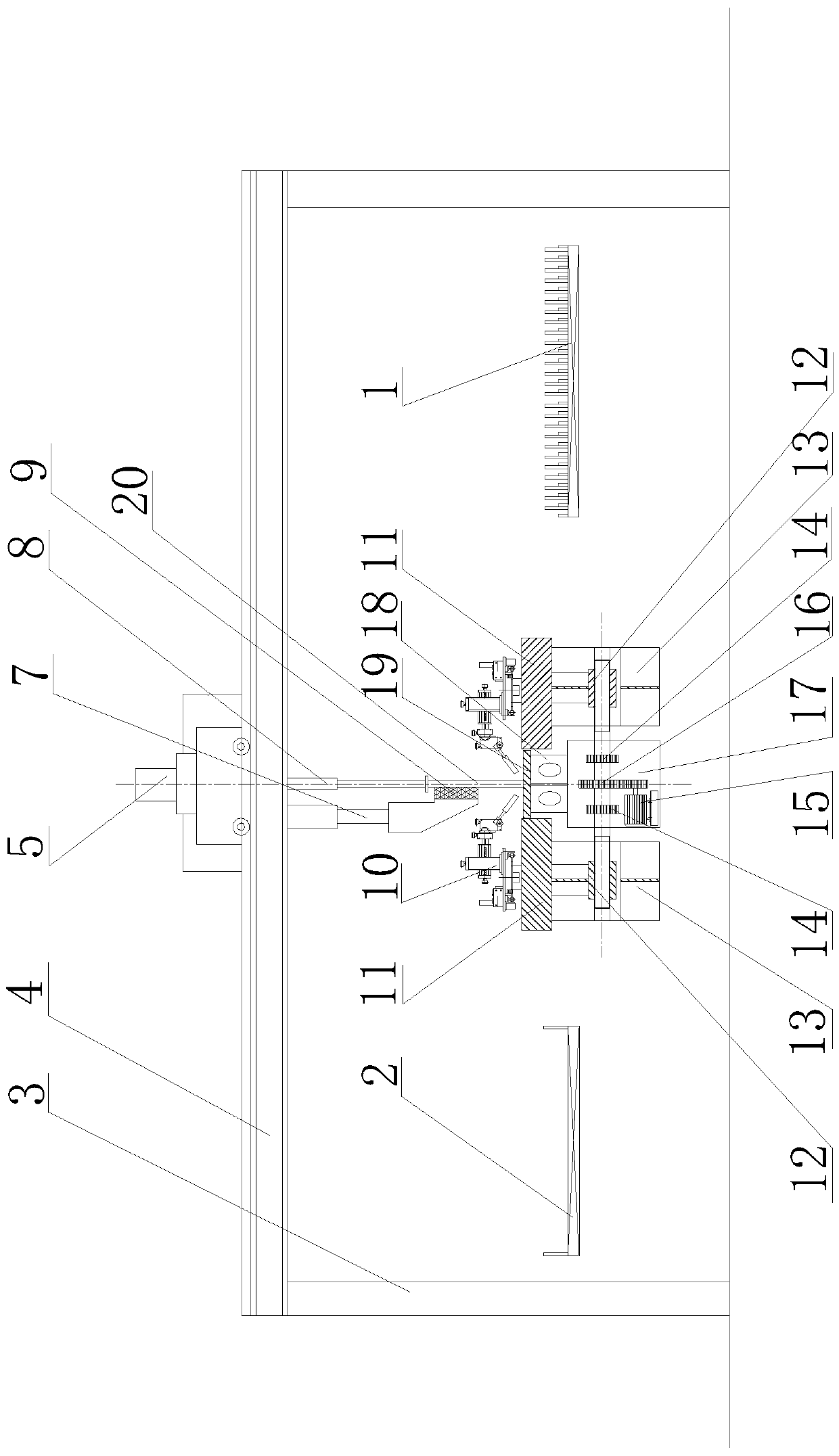

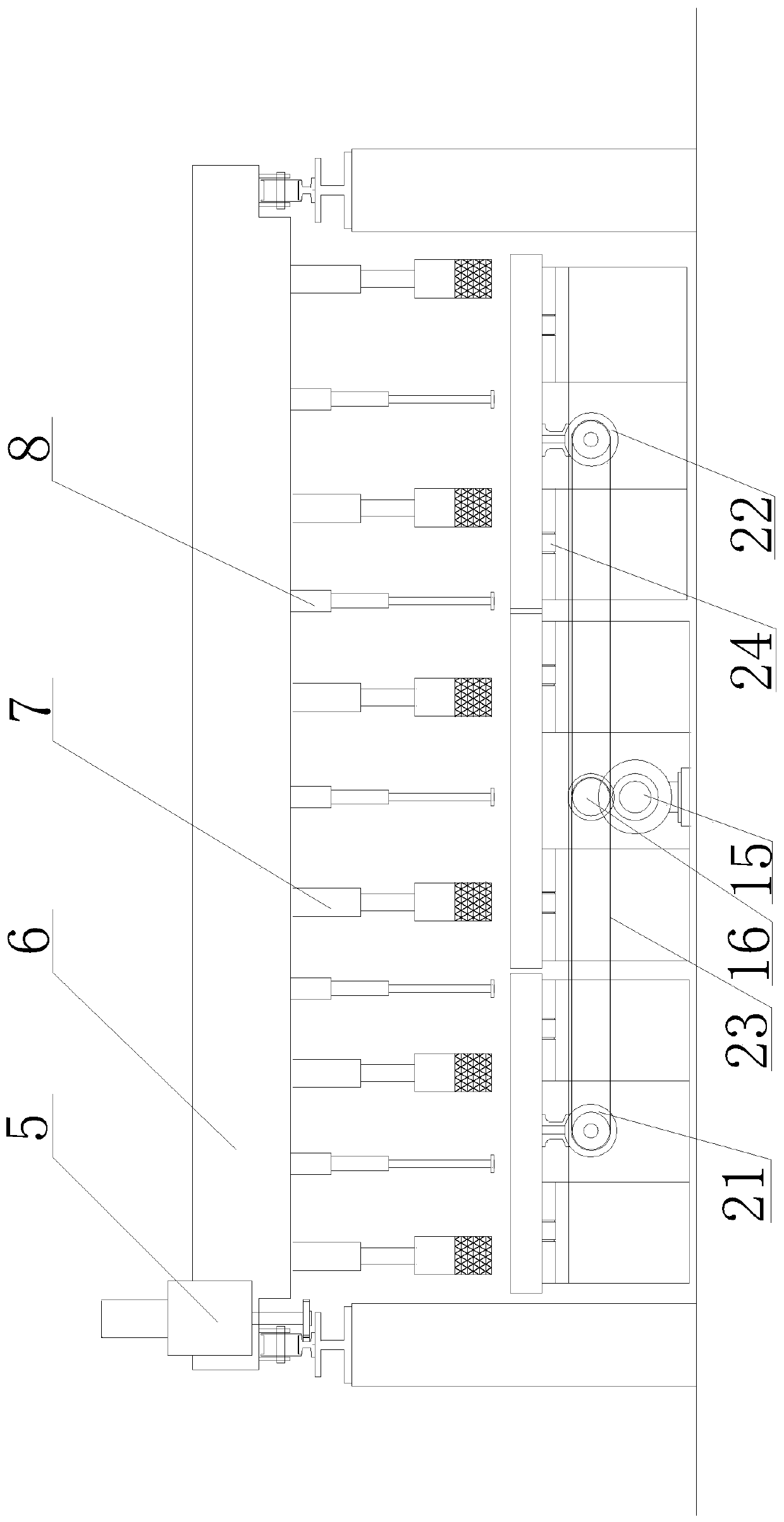

[0021] Such as figure 1 As shown, the present embodiment provides a thin-walled T-shaped bar automatic assembly and welding device, including:

[0022] The gantry structure is set across the top of the T-shaped material selection area 1, the T-shaped material welding area, and the welded T-shaped material placement area 2. The profiles are hoisted to the post-welding T profile placement area 2 for storage;

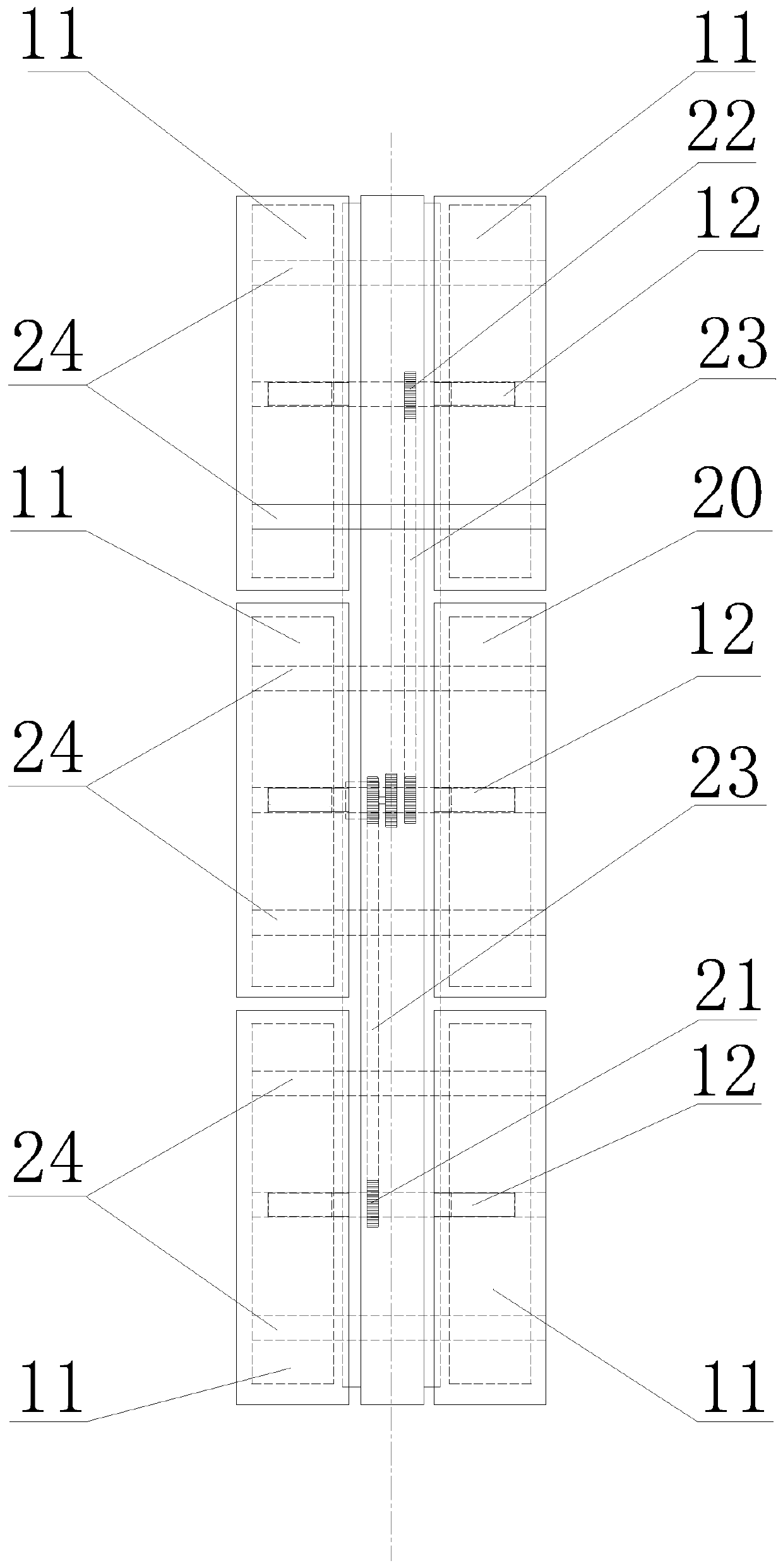

[0023] The welding mechanism is arranged in the T-shaped bar welding area, including a welding platform 17 for fixing and welding the T-shaped bar material, and two platform main boards 13 that are arranged in parallel on both sides of the welding platform 17, and the platform main board 13 is provided with The support slider 11 that can be relatively translated in the horizontal direction is used for centering and clamping the panel 19 of the T-shaped bar; it also includes a driving machine 15 for driving the movement of the supporting slider 11, and the driving machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com