Multifunctional micro-plastic forming system

A microplastic and multifunctional technology, applied in the direction of microstructure technology, microstructure devices, etc., can solve the problems of single forming method and poor surface quality of formed parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

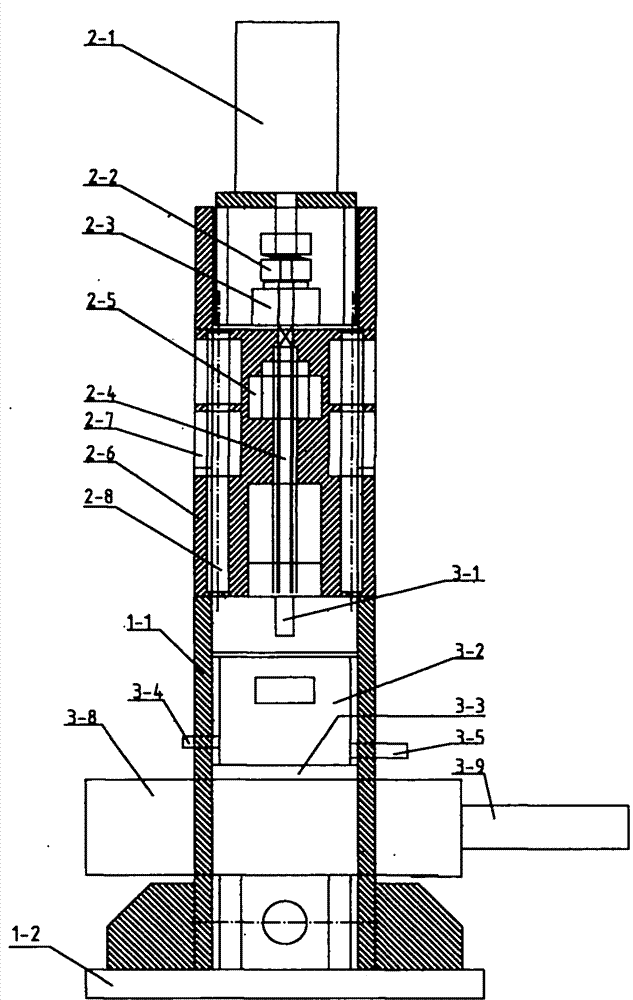

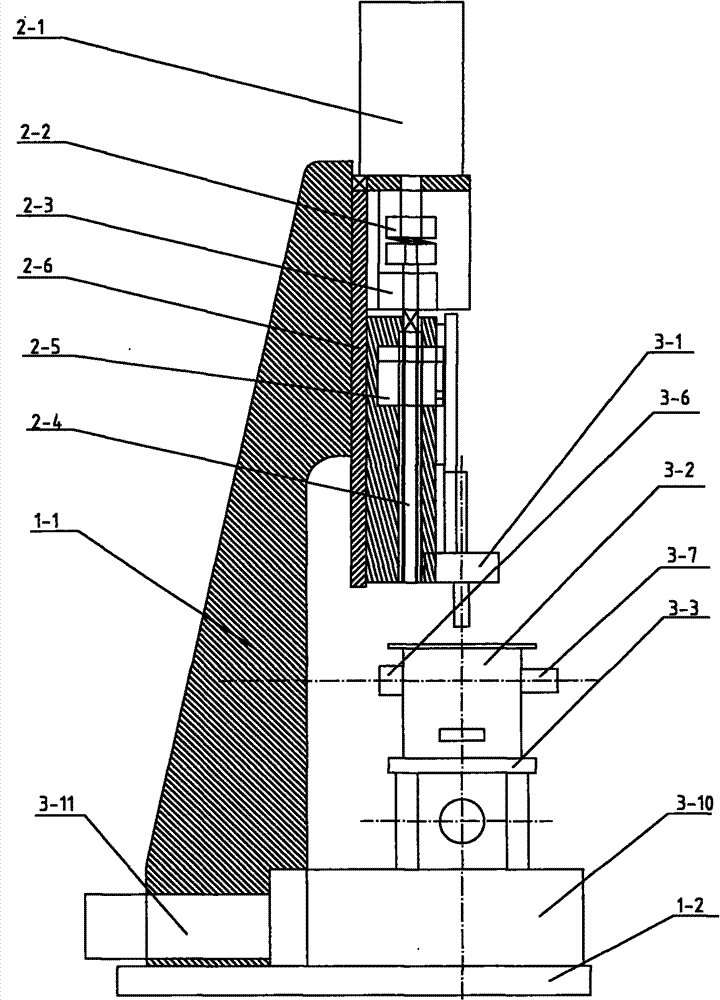

[0027] like Figure 1-2 As shown, the multifunctional microplastic forming system of the present invention is composed of a support mechanism, a transmission mechanism, and a forming mechanism. The transmission mechanism is installed on the support mechanism, and the mold on the forming mechanism corresponds to the punch on the transmission mechanism. Among them, the support mechanism includes a bracket 1-1, a base 1-2, and the bracket 1-1 is installed on the base 1-2; the transmission mechanism includes a servo motor I2-1, a reducer 2-2, a coupling 2-3, a wire Bar 2-4, nut 2-5, baffle plate 2-6, slide block 2-7, slideway 2-8, etc., the top of bracket 1-1 is fixed with servo motor I2-1, the lower end of servo motor I2-1 Connect the reducer 2-2, the reducer 2-2 is used to control the output torque, the output end (lower end) of the reducer 2-2 is connected to the lead screw 2-4 through the coupling 2-3, and the coupling 2-3 While transmitting the rotation, the dynamic performa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com