Method for combining sludge treatment and straw treatment to produce marsh gas

A technology of sludge treatment and straw, which is applied in the direction of biological sludge treatment, biological organic part treatment, fertilizer made from biological waste, etc., can solve the problems of serious pollution, large energy consumption, etc., and achieve large vehicle transportation and storage occupation The effect of small area and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

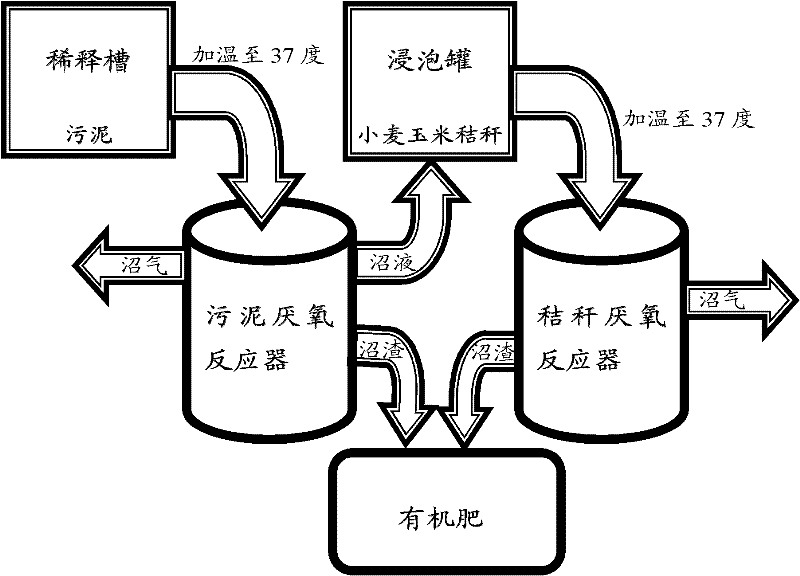

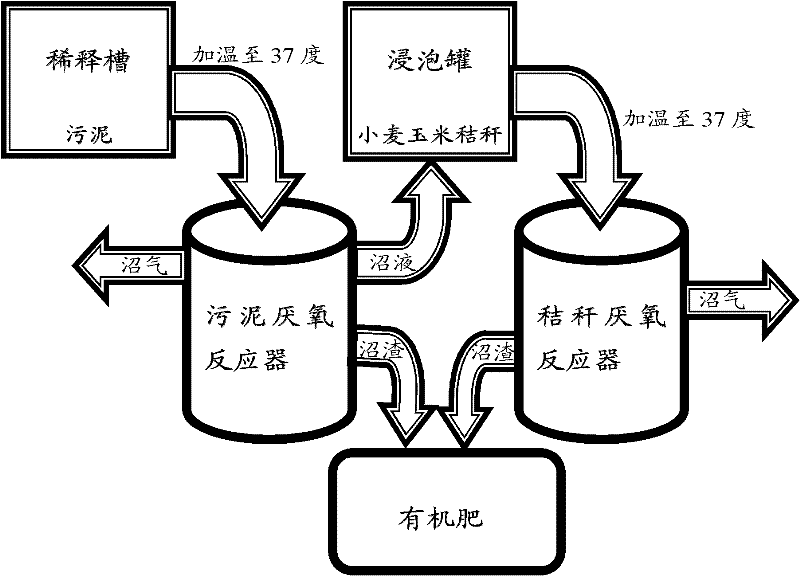

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, the equipment used in the method of the present invention has a dilution tank connected to a sludge anaerobic reactor, and the sludge anaerobic reactor is connected to a soaking tank at the same time, and the soaking tank is further connected to a straw anaerobic reactor .

[0020] Such as figure 1 Shown, a kind of combined sludge treatment and stalk treatment of the present invention are with the method for producing biogas, and its concrete steps are as follows:

[0021] Step 1: inject the sludge with 80% water content discharged from the domestic sewage treatment plant into the dilution tank and add water to dilute it to a water content of 93%-94%; warm the diluted sludge to 37°C and transfer it to the sludge drain The anaerobic reaction is carried out in the oxygen reactor, and biogas can be generated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com