Solid polycarboxylate-type slump retaining agent and preparation method thereof

A technology of polycarboxylic acid series and slump retaining agent is applied in the field of preparation of solid polycarboxylic acid series slump retaining agent and solid slump retaining agent. Poison, low cost of transportation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

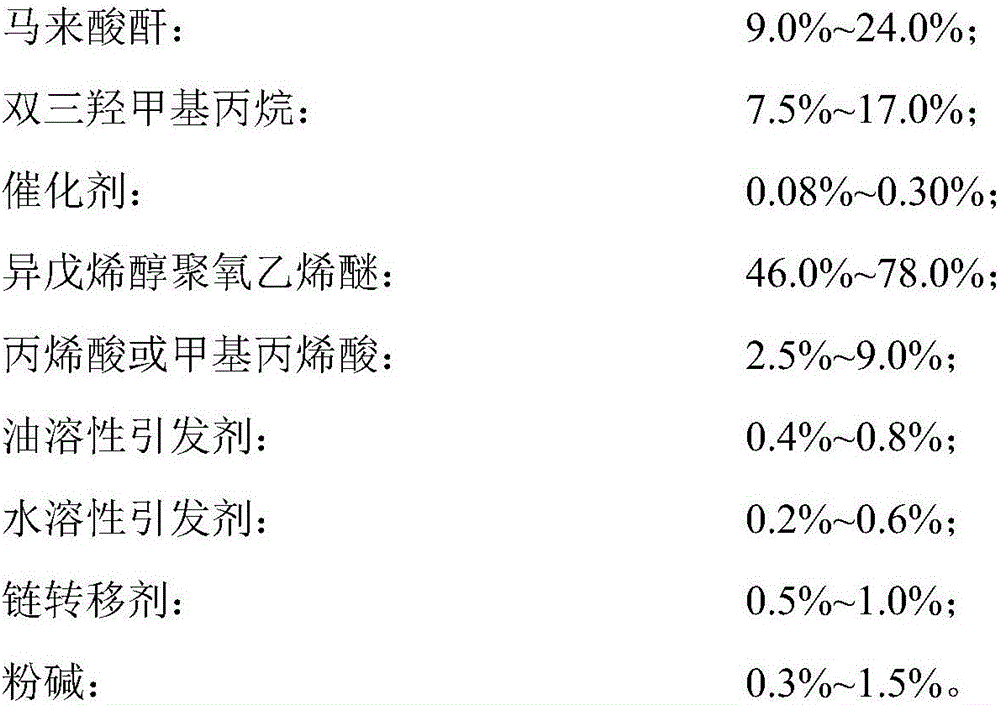

Method used

Image

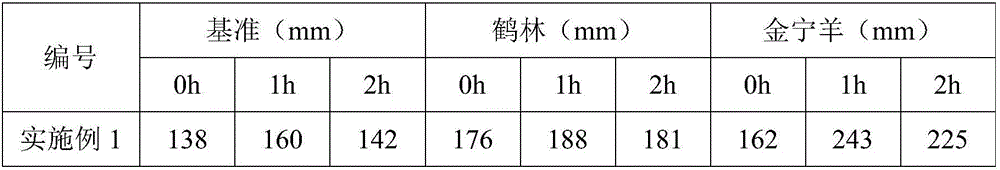

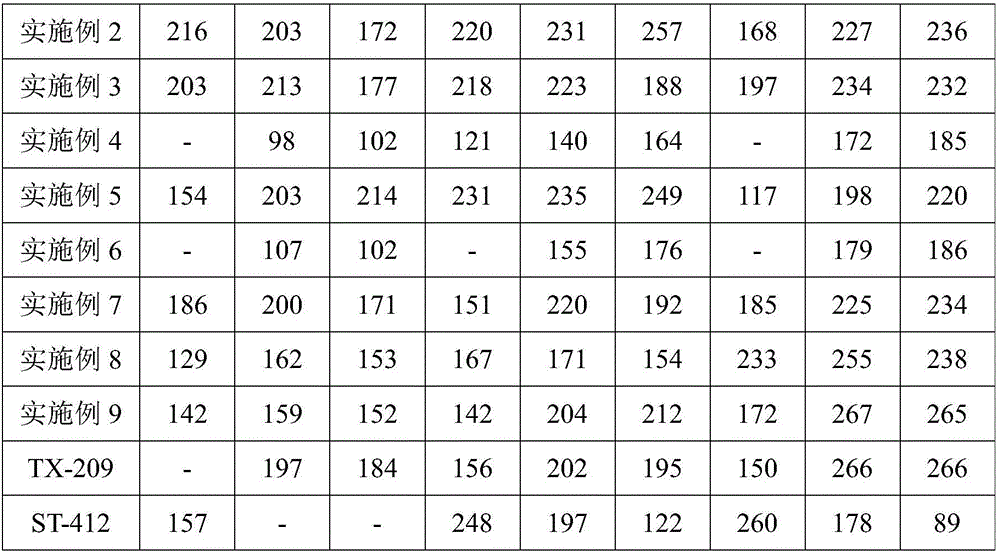

Examples

Embodiment 1

[0029] Add 112.4 parts of ditrimethylolpropane to the reaction kettle equipped with a thermometer, a stirring blade, a constant flow pump, a condenser and a water separator, and raise the temperature to 70°C under stirring until the bottom material is completely melted; 108.0 parts of horse Add anhydride slowly in 3 to 4 times, with an interval of 10 minutes between each time. After the addition, add 2.0 parts of p-toluenesulfonic acid at one time, then raise the temperature to 95°C-100°C, keep the reaction for 4.5 hours, and cool down to 60°C-70°C. ℃; add 712 parts of isopentenol polyoxyethylene ether (the average added mole number of ethylene oxide is 54), stir and melt, then add 4.7 parts of benzoyl peroxide and stir to dissolve; then add 4.7 parts of sodium persulfate, 7.7 1 part of octyl thioglycolate and 42.5 parts of acrylic acid to make a mixed solution, and use a constant current pump to drip it within 3.5 hours to 4 hours; after dropping, continue to keep warm for 2 h...

Embodiment 2

[0031] Add 105.0 parts of ditrimethylolpropane to a reaction kettle equipped with a thermometer, a stirring blade, a constant flow pump, a condenser and a water separator, and raise the temperature to 70°C under stirring until the bottom material is completely melted; 122.3 parts of horse Add the acid anhydride slowly in 3 to 4 times, with an interval of 10 minutes between each time. After the addition, add 1.2 parts of p-toluenesulfonic acid at one time, then raise the temperature to 105 ° C ~ 110 ° C, keep the reaction for 3 hours to 4 hours, and cool down to 60 ℃~70℃; add 652 parts of isopentenol polyoxyethylene ether (the average added mole number of ethylene oxide is 36), stir and melt, then add 4.9 parts of azobisisoheptanonitrile and stir to dissolve; then add 4.9 parts of Ammonium sulfate, 9.8 parts of butanethiol and 85.5 parts of methacrylic acid are formulated into a mixed solution, and are dripped with a constant current pump within 2.5 hours to 3 hours; after the d...

Embodiment 3

[0033]Add 162.8 parts of ditrimethylolpropane to the reaction kettle equipped with thermometer, stirring paddle, constant flow pump, condenser and water separator, and heat up to 70°C under stirring until the bottom material is completely melted; 220.8 parts of horse Add acid anhydride slowly in 3 to 4 times, with an interval of 10 minutes each time. After the addition, add 2.7 parts of sulfamic acid at one time, then raise the temperature to 95°C to 100°C, keep the temperature for 2.5 hours to 3 hours, and then cool down to 60°C ~70°C; add 495 parts of isopentenol polyoxyethylene ether (the average added mole number of ethylene oxide is 27), stir and melt, then add 6.6 parts of benzoyl peroxide and stir to dissolve; then add 2.9 parts of sodium persulfate , 7.8 parts of octyl 3-mercaptopropionate and 87.5 parts of methacrylic acid to make a mixed solution, and drop it with a constant flow pump within 3 hours; after dropping, continue to keep warm for 3.5 hours to 4 hours, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com