Metal baseband-shaped distributed optical fiber sensor

A distributed optical fiber and optical fiber sensor technology, applied in instruments, scientific instruments, optical devices, etc., can solve the problems of lack of pertinence, sensor structure affecting strain temperature transfer, inconvenient sensor layout and installation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The material of the metal sheet belt 5 has a certain strength and meets certain requirements of ductility, deformability, machinability and corrosion resistance. Especially copper, copper alloy, aluminum, aluminum alloy or stainless steel sheets, etc., strips and sheets of other alloys can also be used.

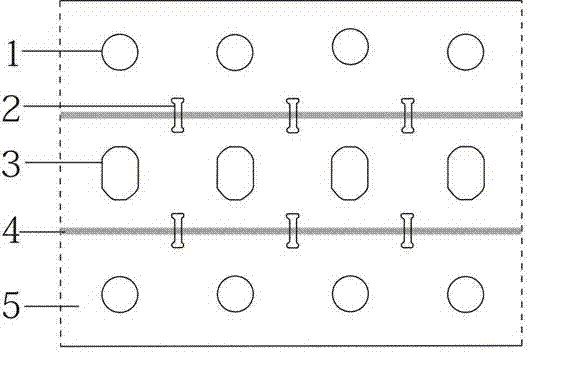

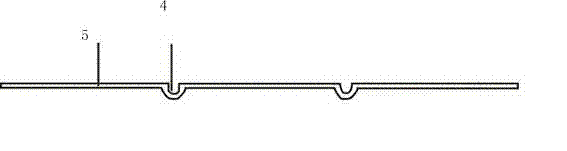

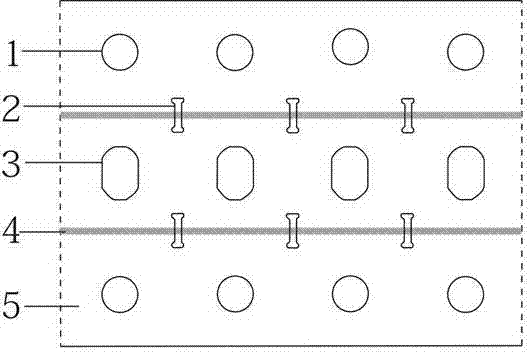

[0021] Shape characteristics of metal sheet strips: the basic shape is a sheet strip with a certain width and a small thickness. Generally, when a single groove is embedded with a single optical fiber, the thickness is 0.05-1mm, and the width is 5-25mm. When there are multiple grooves, the width increases correspondingly, and the thickness remains unchanged. One or more parallel grooves are arranged on the metal sheet belt, and the depth and width of the grooves are based on the size of the sensing optical fiber. Hollow holes and hollow stripes are arranged on the metal foil base belt. The hollow stripes are perpendicular to the groove lines. There are hollow strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Groove depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com