Control input and output circuit for alternating current servo control system for electric fork truck

An input and output circuit, AC servo technology, applied in sequence/logic controller program control, electric vehicle, electrical program control and other directions, can solve the problem that the control accuracy, safety, reliability and anti-interference ability cannot fully meet the requirements, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

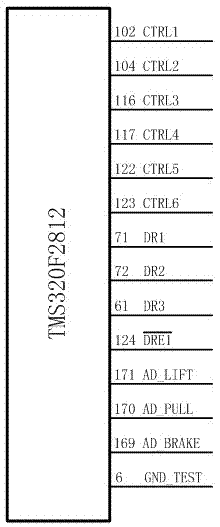

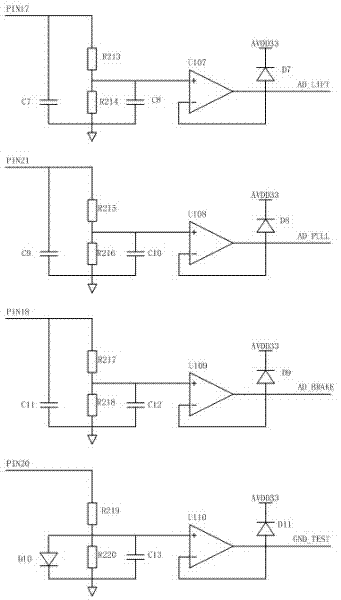

[0030] A control input and output circuit of an AC servo control system for an electric forklift includes a TMS320F2812 digital processing chip, a switch control signal input circuit, an analog control signal input circuit, and a switch control signal output circuit.

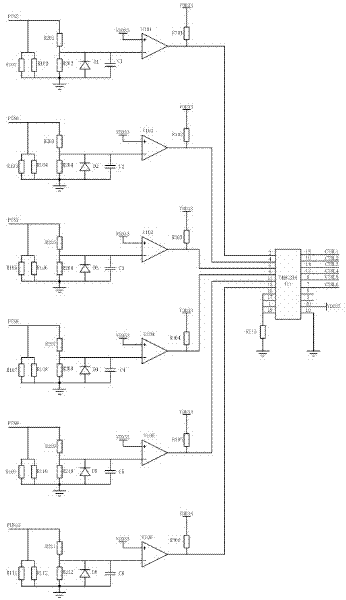

[0031] Such as figure 2 As shown, the switch control signal input circuit includes thirteen pull-down resistors, twelve voltage divider resistors, six pull-up resistors, six clamp diodes, six filter capacitors, six operational amplifiers, and a driver chip 74HC244.

[0032] One end of the first pull-down resistor R101 is connected with one end of the second pull-down resistor R102 and one end of the first voltage dividing resistor R201 as the input end of the seat switch signal; the other end of the first voltage dividing resistor R201 is connected with the second voltage dividing resistor One end of R202, the cathode of the first clamping diode D1, one end of the first filter capacitor C1, and the inverting in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com