Display system with capacitive touch panel and manufacturing method thereof

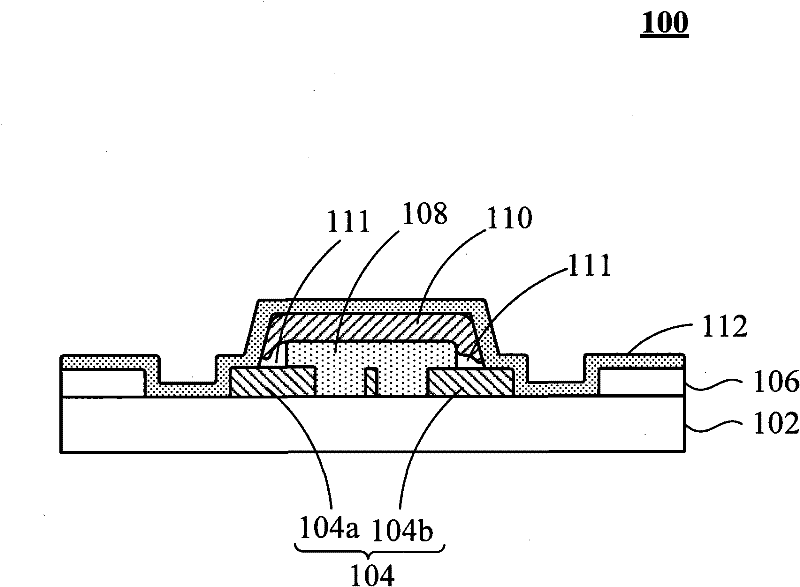

A technology of capacitive touch and display system, which is applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the process steps of capacitive touch panel 100 and the limitation of material selection, and the inability to transmit signals To the problems of metal wires and uneven thickness of the stack layer 110, it can improve the process yield, solve the poor electrical contact, and improve the step coverage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention are described in detail by the accompanying drawings and the following descriptions. In different drawings, the same component symbols represent the same or similar components.

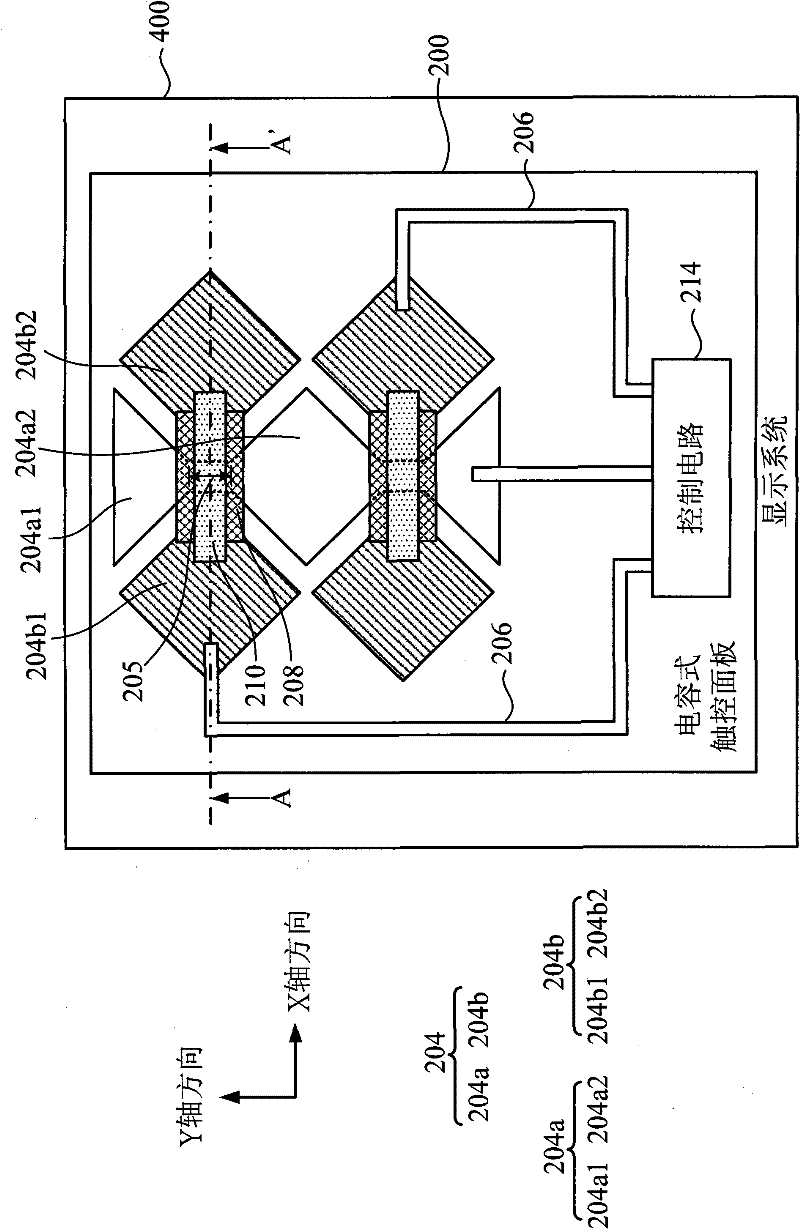

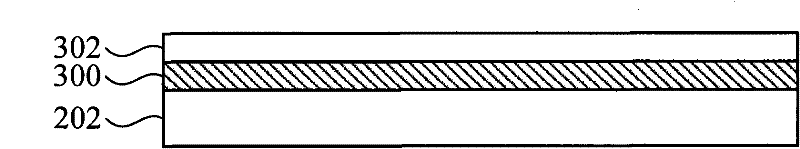

[0025] refer to figure 2 , which shows a top view of the display system 400 with the capacitive touch panel 200 according to the first embodiment of the present invention. A capacitive touch panel (capacitive touch panel) 200 mainly includes a substrate 202, electrode lines 204, a plurality of signal lines 206, a dielectric layer (dielectric layer) 208, an electrode bridge structure 210, and a passivation layer (passivation layer) 212 (marked At Figure 3F ). The electrode circuit 204 is connected to the control circuit 214 through the wire formed by the signal line 206 , and the control circuit 214 is used for processing the sensing signal from the electrode circuit 204 .

[0026] The electrode circuit 204 is formed on the substrate 202, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com