High-performance sintered neodymium-iron-boron (Nd-Fe-B) rare-earth permanent magnet material and manufacturing method thereof

A technology of rare earth permanent magnets and manufacturing methods, which is applied in the fields of magnetic materials, inductance/transformer/magnet manufacturing, and the magnetism of inorganic materials, and can solve problems such as failure to meet the requirements of the main phase of the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

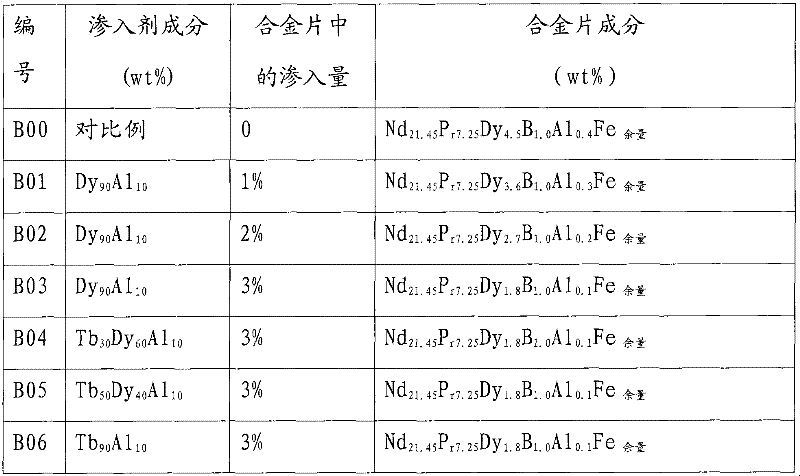

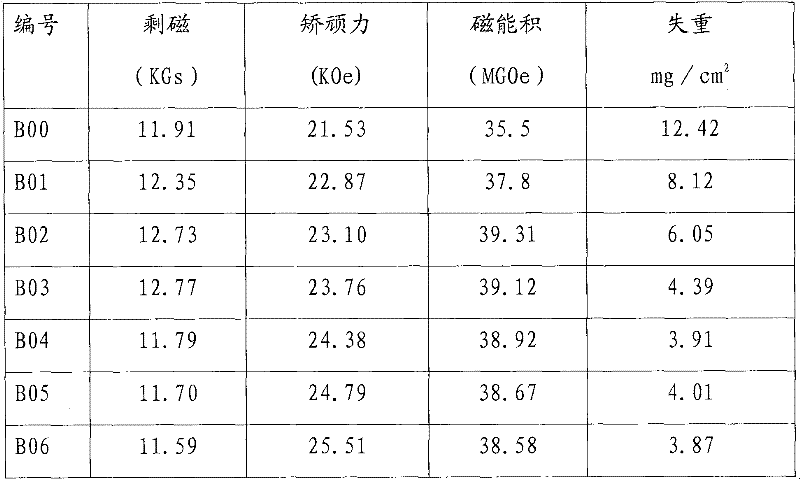

[0028] Ra-Al metal infiltrant, that is, without Co, Cu, Ga, Zr. Compared with the prior art (comparative example), with the increase of the metal infiltrant, the magnetic properties of the magnet increase, especially the coercive force increases significantly; in the metal infiltrant, when Dy is replaced by Tb, the coercive force increases even more obvious. Table 1 shows the composition of the metal infiltrant, the content of the metal infiltrant in the corresponding alloy sheet and the composition of the corresponding alloy sheet. Table 2 is the magnetic properties and corrosion resistance corresponding to the numbers in Table 1. Wherein the number B00 is a comparative example of the prior art.

[0029] Table 1:

[0030]

[0031] Note: wt% means weight percentage

[0032] Table 2

[0033]

Embodiment 2

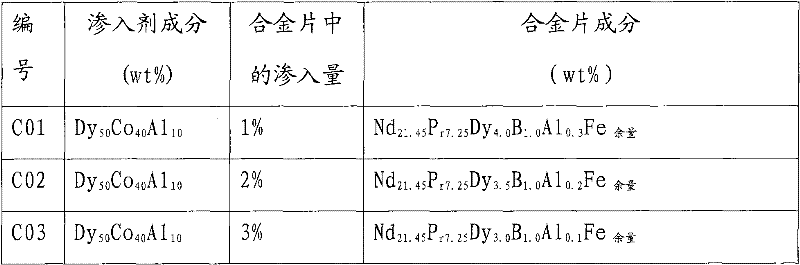

[0035] When X in the Ra-Al-X metal infiltrant is Co, the magnetic performance of the magnet increases with the increase of the metal infiltrant, but the weight loss decreases significantly. The composition of the metal infiltrant and the alloy sheet, and the infiltration amount parameters of the metal infiltrant in the alloy sheet are listed in Table 3; the corresponding properties are listed in Table 4.

[0036] table 3:

[0037]

[0038] Note: wt% means weight percentage

[0039] Table 4

[0040]

Embodiment 3

[0042] When X in the Ra-Al-X metal infiltrant is Co or Cu, it can be seen from Table 5 and Table 6 that with the increase of the metal infiltrant, the magnetic properties of the magnet are improved, but the weight loss is significantly reduced.

[0043] table 5:

[0044]

[0045]

[0046] Note: wt% means weight percentage

[0047] Table 6

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com