Lithium-nickel-cobalt-manganese oxide composite material particle and preparation method thereof as well as battery

A composite material, lithium-nickel-cobalt-manganese technology, applied in the direction of battery electrodes, secondary batteries, non-aqueous electrolyte storage battery electrodes, etc. Covering and other issues, to achieve the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The positive electrode active material particles are lithium cobaltate particles. The aluminum phosphate-lithium cobalt oxide composite material particles include lithium cobalt oxide particles and an aluminum phosphate layer coated on the surface of the lithium cobalt oxide particles.

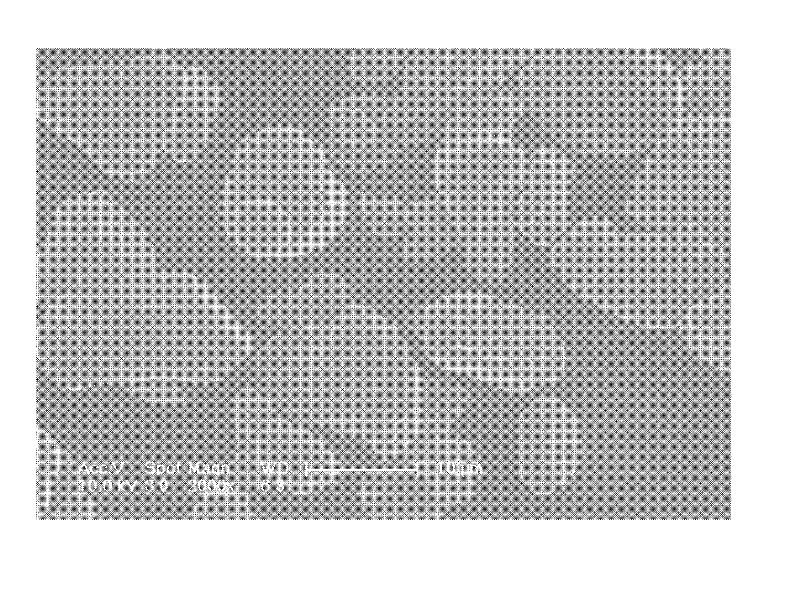

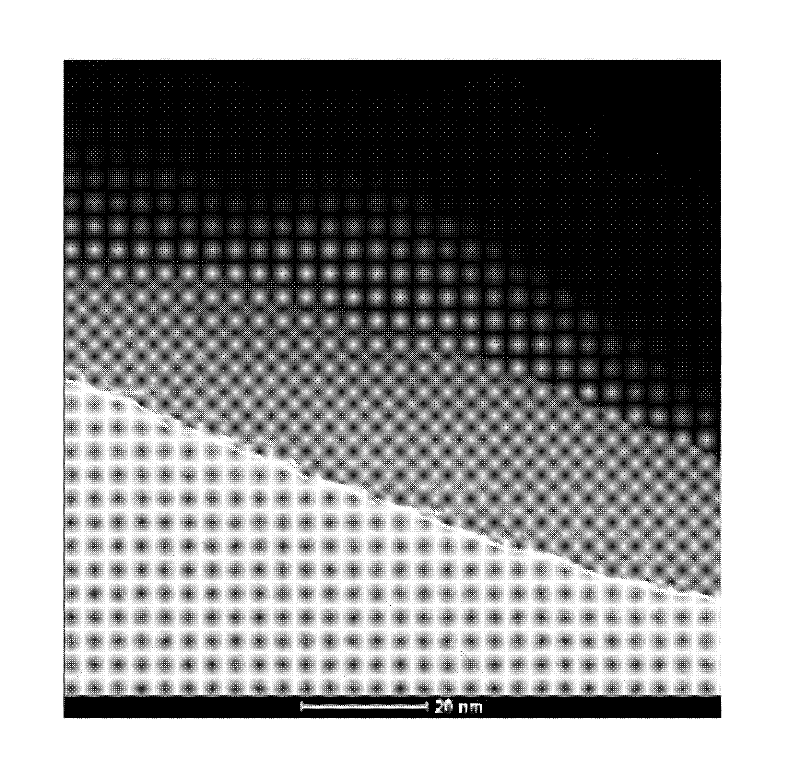

[0049] In the preparation of the aluminum phosphate-lithium cobaltate composite material particles, the aluminum nitrate solution is a solution of aluminum nitrate in ethanol. The aluminum nitrate solution has a volume of 30 milliliters and a molar concentration of 0.16 mol / liter. The added amount of the lithium cobaltate particles is 100g. The phosphate solution is (NH 4 ) 2 HPO 4 aqueous solution. The aluminum phosphate-lithium cobaltate composite particle samples were prepared under the conditions that the heat treatment temperature was 400° C. to 600° C., and the aluminum phosphate layer accounted for 1% by mass of the total mass. see figure 2 and image 3 , in the obtained...

Embodiment 2

[0051] The positive electrode active material particles are lithium nickel cobalt manganese oxide particles, and the chemical formula is LiN 1 / 3 co 1 / 3 mn 1 / 3 o 2 . The aluminum phosphate-lithium nickel cobalt manganese oxide composite particle comprises lithium nickel cobalt manganese oxide particle and an aluminum phosphate layer coated on the surface of the lithium nickel cobalt manganese oxide particle.

[0052] The preparation method of the aluminum phosphate-lithium nickel cobalt manganese oxide composite material particles is the same as the preparation method of the aluminum phosphate-lithium cobalt oxide composite material particles in the above-mentioned Example 1, and the heat treatment temperature is 600°C. The aluminum phosphate-lithium nickel cobalt manganese oxide composite particle is used as the positive electrode active material, mixed with a certain proportion of conductive agent and binder and evenly coated on the surface of the positive electrode curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com