Manufacturing method of Schottky diode with high reverse-blocking performance

A technology of Schottky diode and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of limiting Schottky diodes, deterioration of reverse blocking characteristics, unsaturated reverse leakage current, etc. problem, to achieve the effect of improving device efficiency, reducing reverse leakage current, and low forward voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

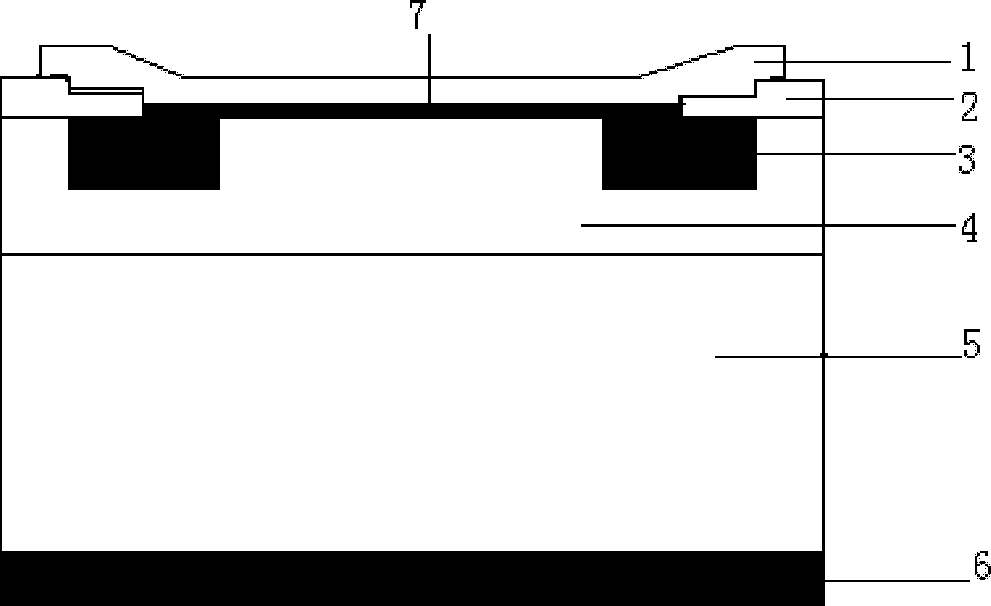

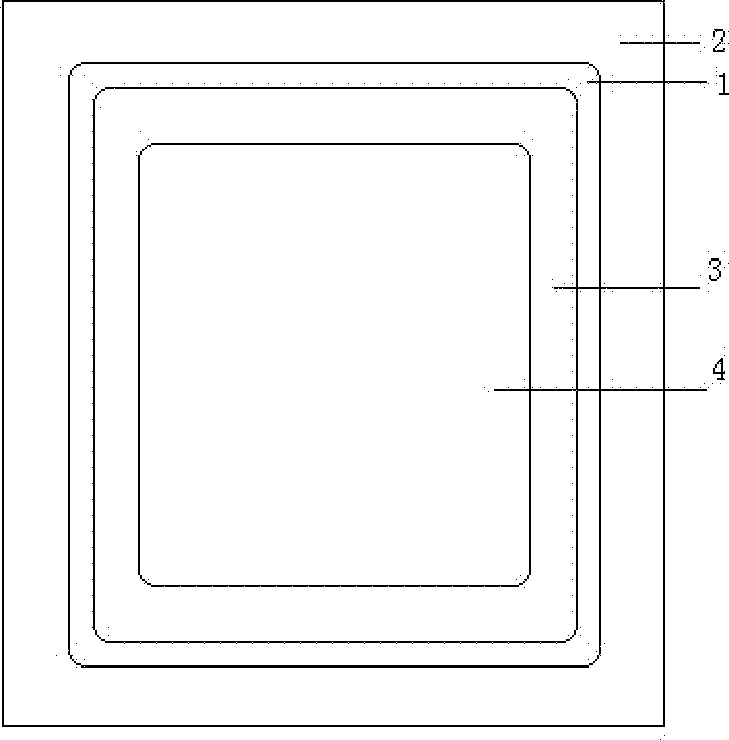

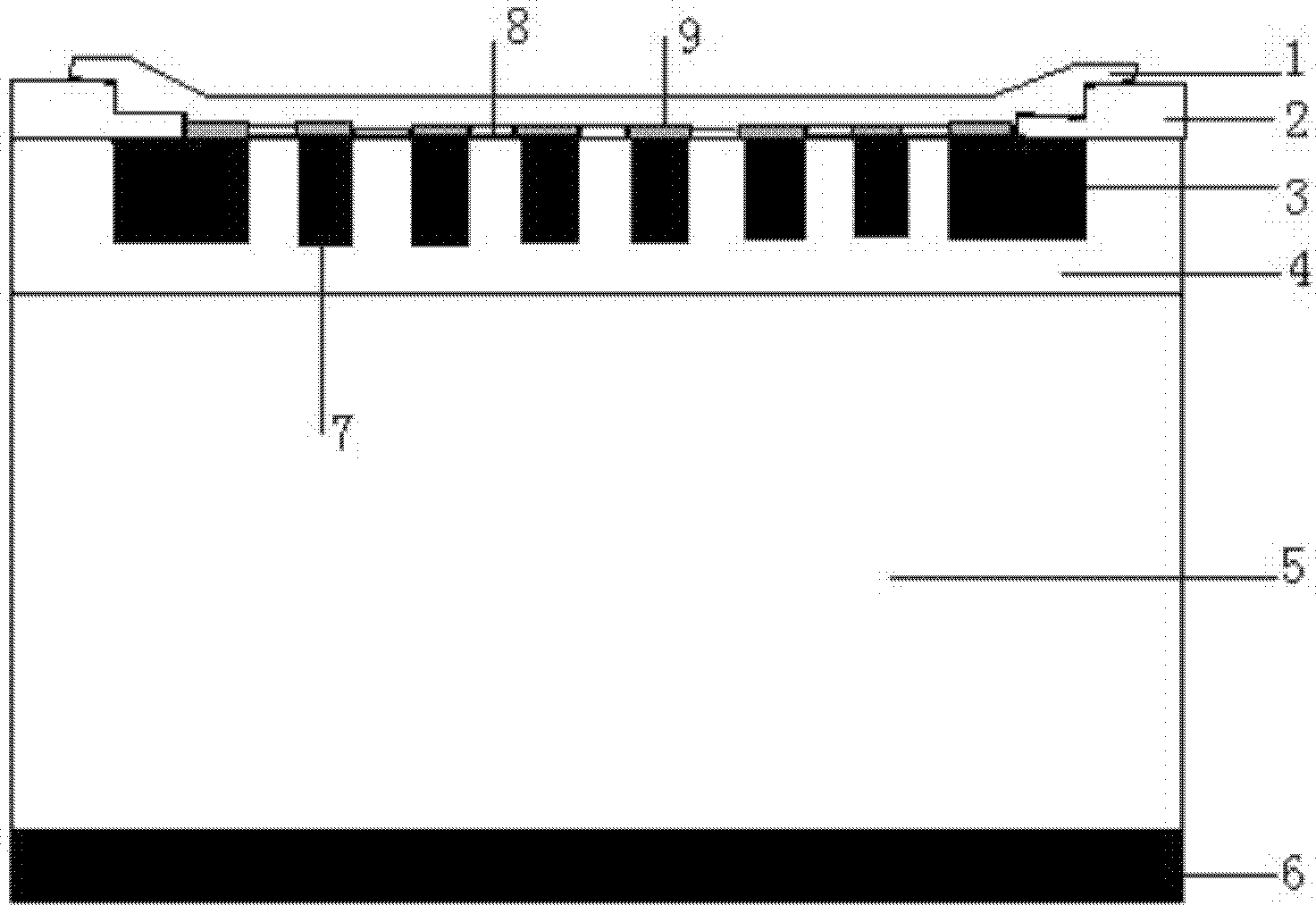

[0012] The patent application of the present invention discloses a Schottky diode with high reverse blocking performance, and its die structure is as follows: image 3 and Figure 4 As shown, its composition includes a heavily doped silicon substrate 5, epitaxially growing a lightly doped epitaxial layer 4 doped with P or AS as a drift region on the heavily doped silicon substrate 5, and implanting ions into the lightly doped epitaxial layer The P-type structure area made, and the upper and lower lead-out electric boards 1,6. The P-type structure region is composed of a P-type ring 3 and a P-type lattice 7 uniformly distributed in the epitaxial layer of the P-type ring 3, and the distance between the nearest adjacent P-type points of the P-type lattice is 5 In the range of -10um, the surface of the epitaxial layer in the P-type ring 3 has a metal layer 8 in Schottky barrier contact, the surface of the P-type structure region has an ohmic metal contact, and the outer edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com