Solar battery assembly of copper-indium-gallium-selenium thin film and preparation method of light absorption layer thereof

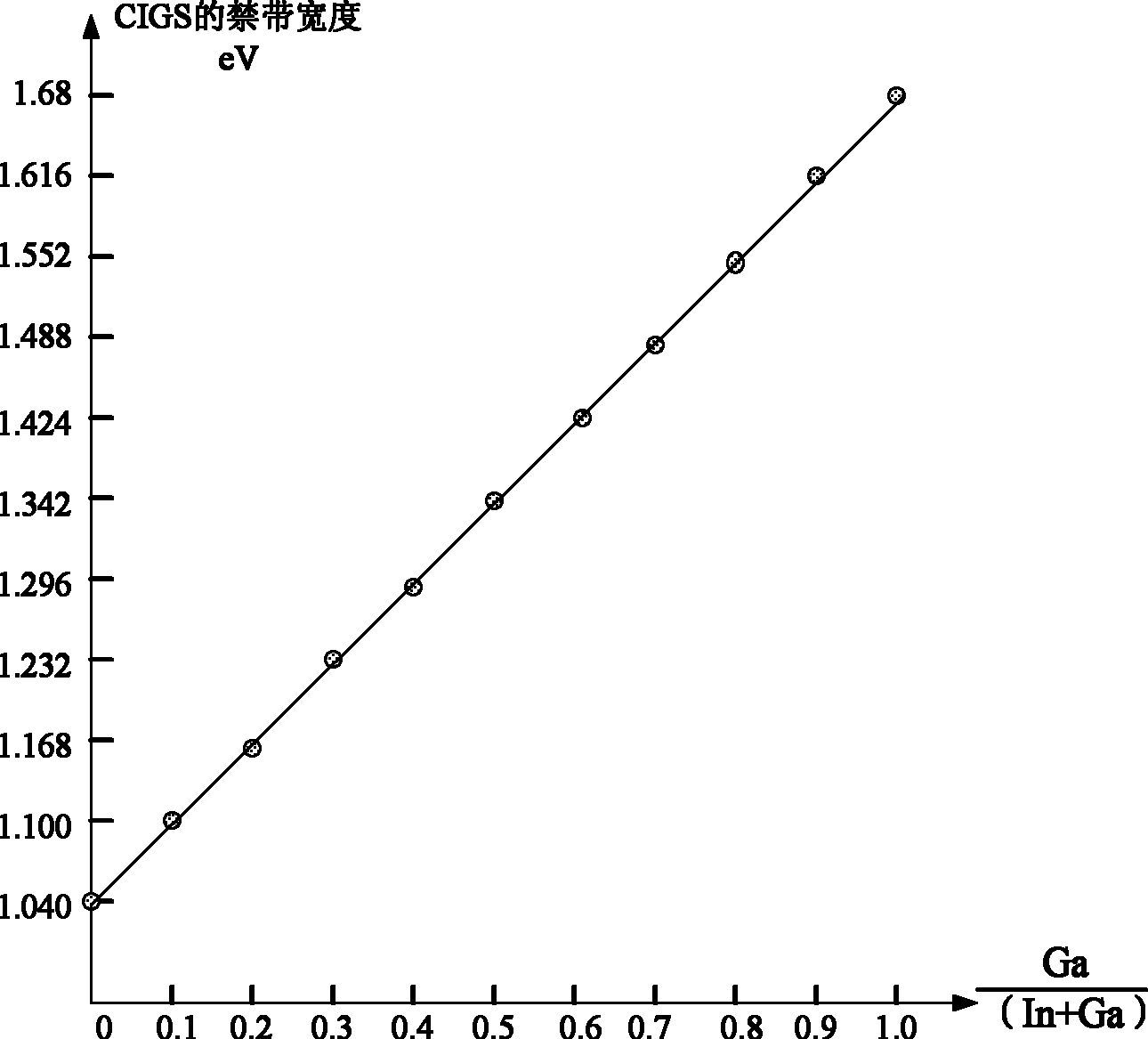

A solar cell and light absorbing layer technology, applied in the field of solar cells, can solve the problems affecting the electrical properties of copper indium gallium selenium thin film solar cells, the inability to accurately realize the energy band structure, and the lack of precise control of the ratio, etc., to achieve excellent electrical properties, The effect of stable quality and high light absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

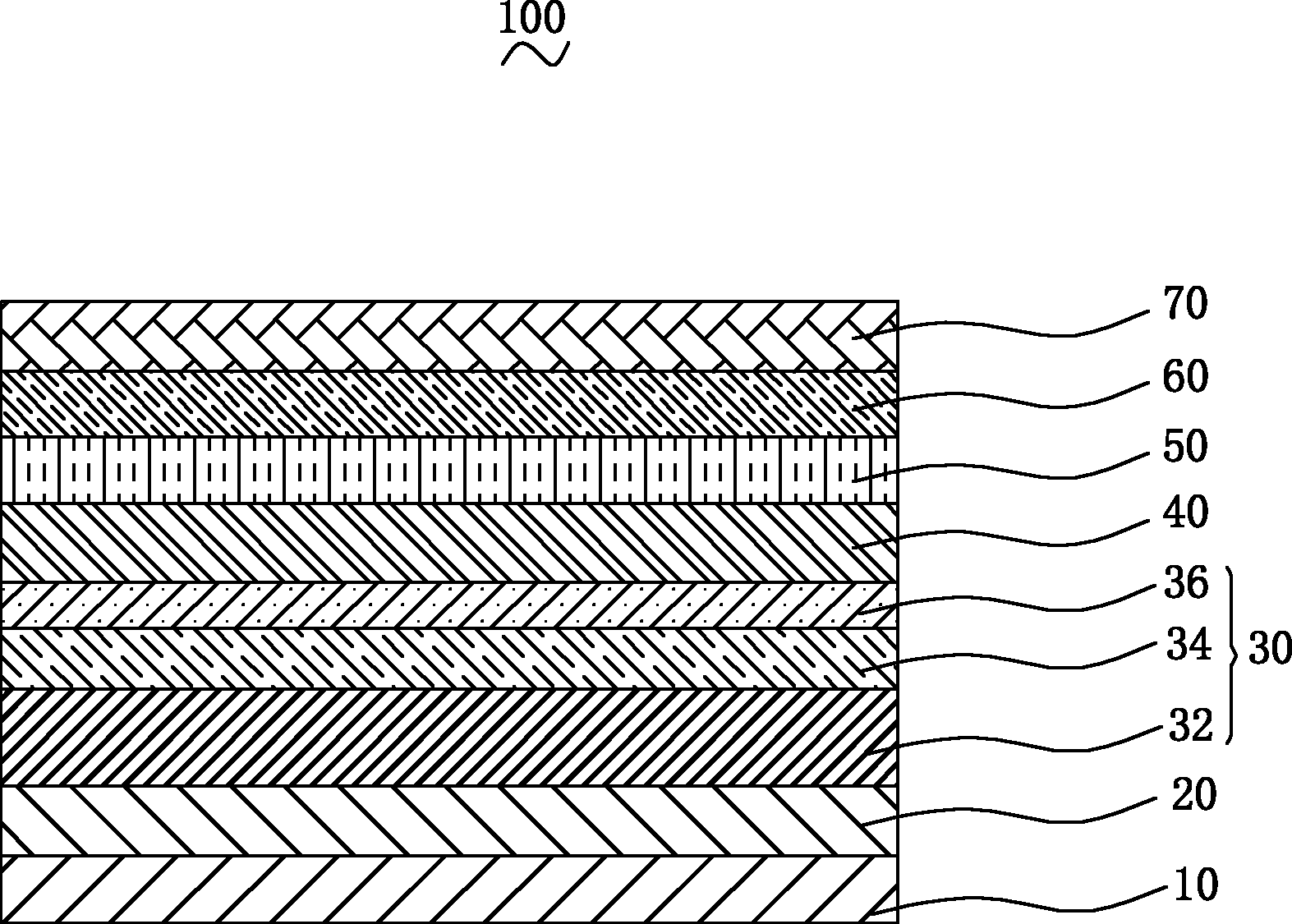

[0095] (1) Preparation of light absorbing layer 30

[0096] The temperature of the substrate 10 is maintained at 450° C., and then the four substances of CIGS are evaporated simultaneously at different temperatures. During the evaporation process, the evaporation temperature of selenium is always kept at 200°C, and the evaporation temperature of copper is always kept at 1300°C. During the evaporation process, the ratio of the evaporation amount of copper to the sum of the evaporation amounts of indium and gallium was 0.8.

[0097] The evaporation process consists of three stages:

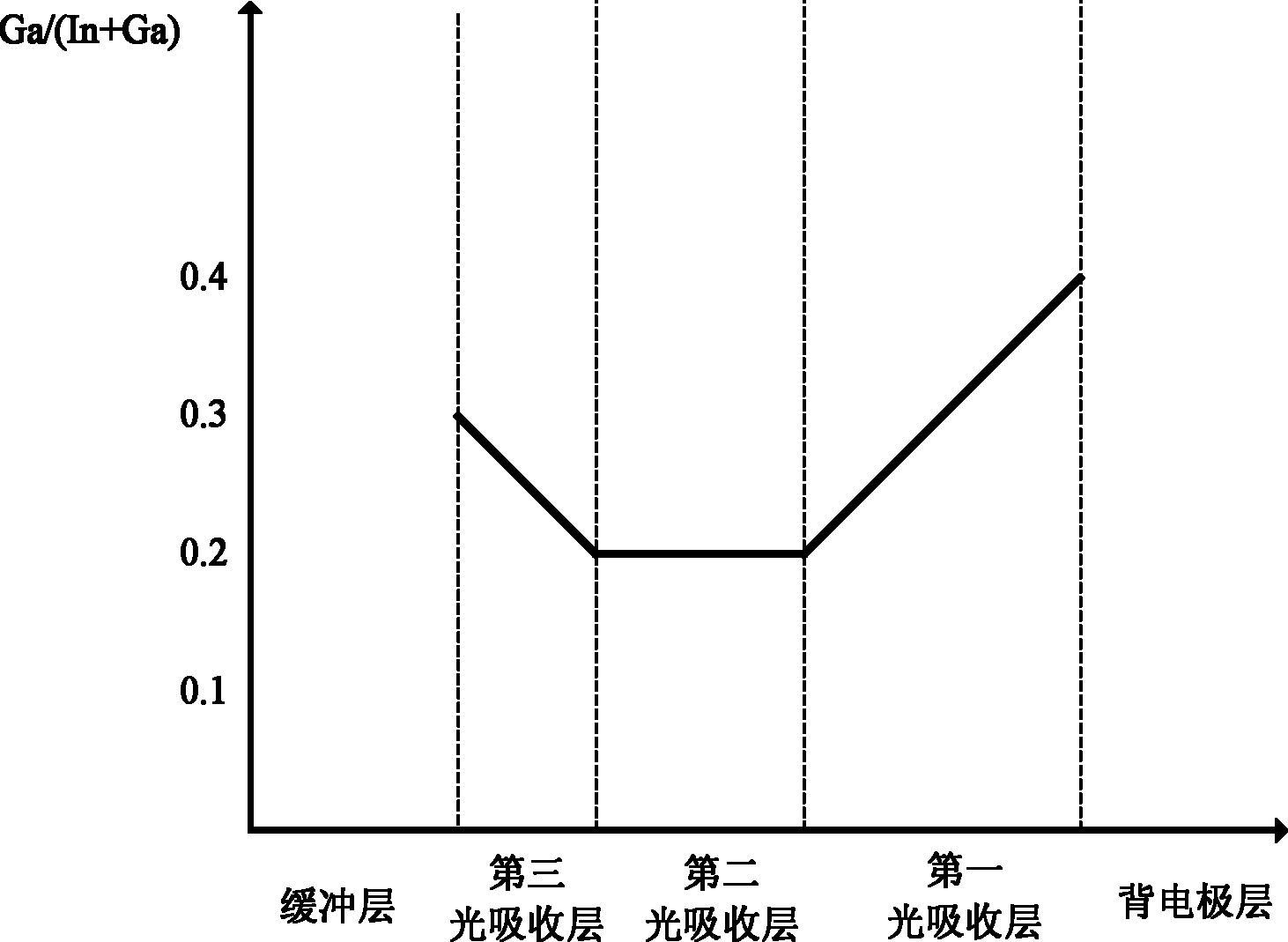

[0098] The first stage: within 10 minutes, the evaporation temperature of indium is gradually and uniformly increased by 20°C from 800°C, and the evaporation temperature of gallium is gradually and uniformly decreased by 20°C from 900°C to form the first light absorbing layer 32 . The thickness of the first light absorbing layer 32 is 1000 nanometers.

[0099] Second stage: after the first stage...

Embodiment 2

[0105] (1) Preparation of light absorbing layer 30

[0106]The temperature of the substrate 10 is maintained at 600° C., and then the four substances of CIGS are evaporated simultaneously at different temperatures. During the evaporation process, the evaporation temperature of selenium is always kept at 300°C, and the evaporation temperature of copper is always kept at 1500°C. During the evaporation process, the ratio of the evaporated amount of copper to the sum of the evaporated amounts of indium and gallium was 0.95.

[0107] The evaporation process consists of three stages:

[0108] The first stage: within 8 minutes, the evaporation temperature of indium is gradually and uniformly increased by 30°C from 1000°C, and the evaporation temperature of gallium is gradually and uniformly decreased by 30°C from 1100°C to form the first light absorbing layer 32 . The thickness of the first light absorbing layer 32 is 1500 nm.

[0109] Second stage: after the first stage, keep th...

Embodiment 3

[0115] (1) Preparation of light absorbing layer 30

[0116] The temperature of the substrate 10 is maintained at 450° C., and then the four substances of CIGS are evaporated simultaneously at different temperatures. During the evaporation process, the evaporation temperature of selenium is kept at 200°C, the evaporation temperature of copper is kept at 1300°C, and the evaporation temperature of indium is kept at 800°C. During the evaporation process, the ratio of the evaporation amount of copper to the sum of the evaporation amounts of indium and gallium was 0.8.

[0117] The evaporation process consists of three stages:

[0118] First stage: within 10 minutes, the evaporation temperature of gallium is gradually and uniformly lowered from 800° C. to 30° C. to form the first light absorbing layer 32 . The thickness of the first light absorbing layer 32 is 1000 nanometers.

[0119] The second stage: after the first stage, keep the evaporation temperature of gallium at 770° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com