Production method for frozen pre-fried glutinous rice cake capable of being heated in microwave oven

A production method, microwave freezing technology, applied in baking, baked food, food science, etc., can solve the problems that glutinous rice ball cake does not have the characteristics and flavor of fried glutinous rice ball cake, and the process is complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

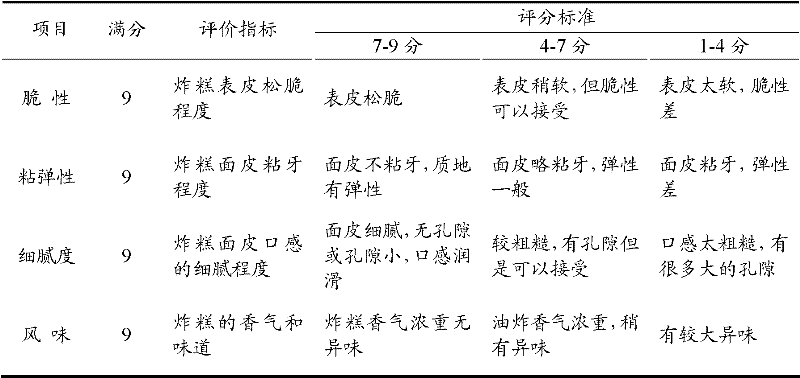

[0081] Example 1 : The effect of the ratio of glutinous rice flour and low-gluten flour on the quality of fried glutinous rice cakes

[0082] Considering that the glutinous rice starch is almost entirely amylopectin, which is highly viscous after gelatinization, if only the glutinous rice flour is used to process the product, it is easy to collapse, stick to the teeth, and difficult to process, so some low-gluten flour is added to increase its amylose Ratio, improve its quality, while reducing costs. In this example, four groups of mixed flours of glutinous rice flour and low-gluten flour were used, and the total mass of each group was 200 g. The ratio of the two flours is shown in Table 2. The specific operation steps are as follows

[0083] A) HLB=9-10 monoglyceride laurate produced by 0.75g Mitsubishi Chemical Co., Ltd. and HLB=16 sucrose laurate produced by 0.4g Mitsubishi Chemical Co., Ltd. were dissolved in 40g water to prepare a stock solution; then

[0084]B) Take ...

Embodiment 2

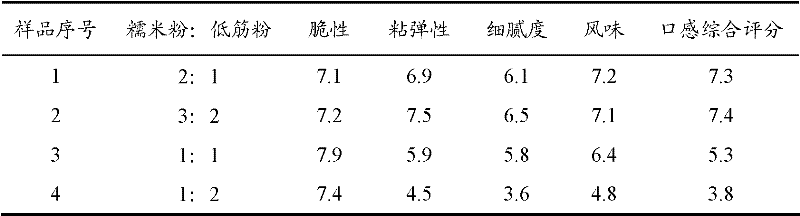

[0092] Example 2 : Effect of moisture content on the quality of fried glutinous rice cake

[0093] Carried out in the same manner as in Example 1, except that sample 2 in Example 1 was used, and the amount of water used during dough was different. The sensory evaluation of fried glutinous rice cake was carried out according to the method described in this specification, and its result is listed in Table 3.

[0094] Table 3: Effect of water content on the quality of fried glutinous rice cakes

[0095]

[0096] The results in Table 3 clearly show that (1) three groups of fried glutinous rice cake samples have obtained good results in terms of brittleness, viscoelasticity, fineness and flavor; (2) determine the water content of sample 2, that is, the amount of water added is 40% of the total weight of the dough is the optimal amount of water.

Embodiment 3

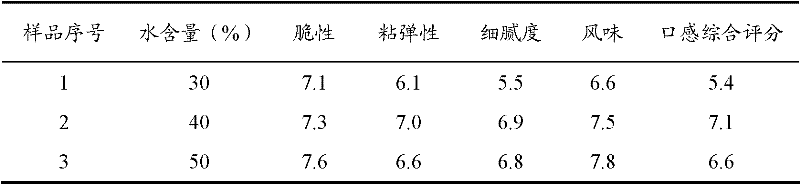

[0097] Example 3 : The effect of water temperature on the quality of fried glutinous rice cakes during kneading

[0098] Carry out in the same manner as Example 1, but use sample 2 in Example 1 to study the impact of water at different temperatures on the quality of fried glutinous rice cakes. Carry out the sensory evaluation of fried glutinous rice cake according to the method described in this description, its result is listed in Table 4.

[0099] Table 4: Effect of water temperature on the quality of fried glutinous rice cakes

[0100]

[0101] The results in Table 4 clearly show that (1) the three groups of fried glutinous rice cake samples obtained good results in terms of brittleness, viscoelasticity, fineness and flavor; (2) the water temperature of sample 3 was determined to be 100°C as the best temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com