Tobacco baking equipment

A flue-cured tobacco and equipment technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of dust and exhaust gas pollution, inaccurate temperature control, and high cost of tobacco leaf curing, and achieve uniform and rapid moisture regain, uniform temperature and humidity, and weight light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

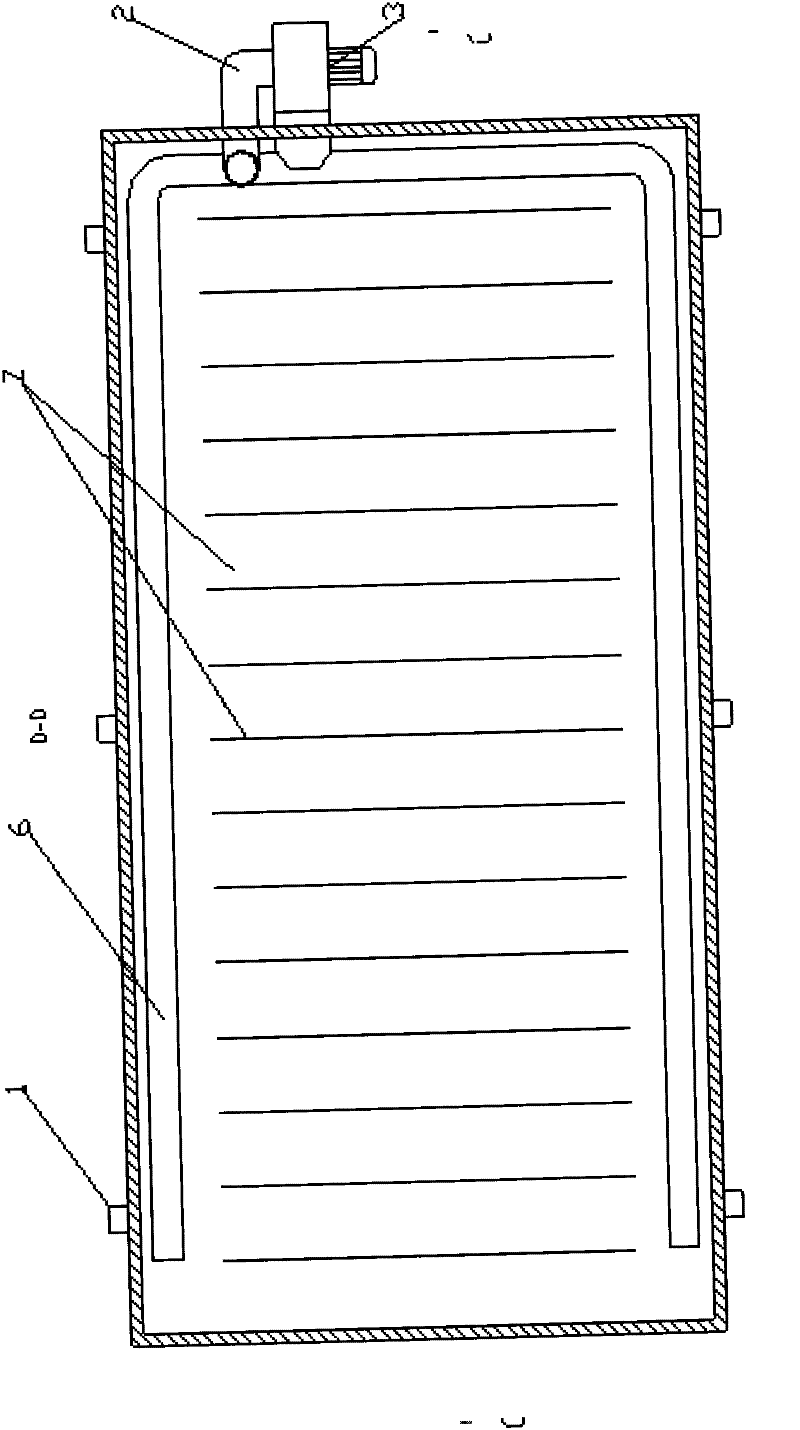

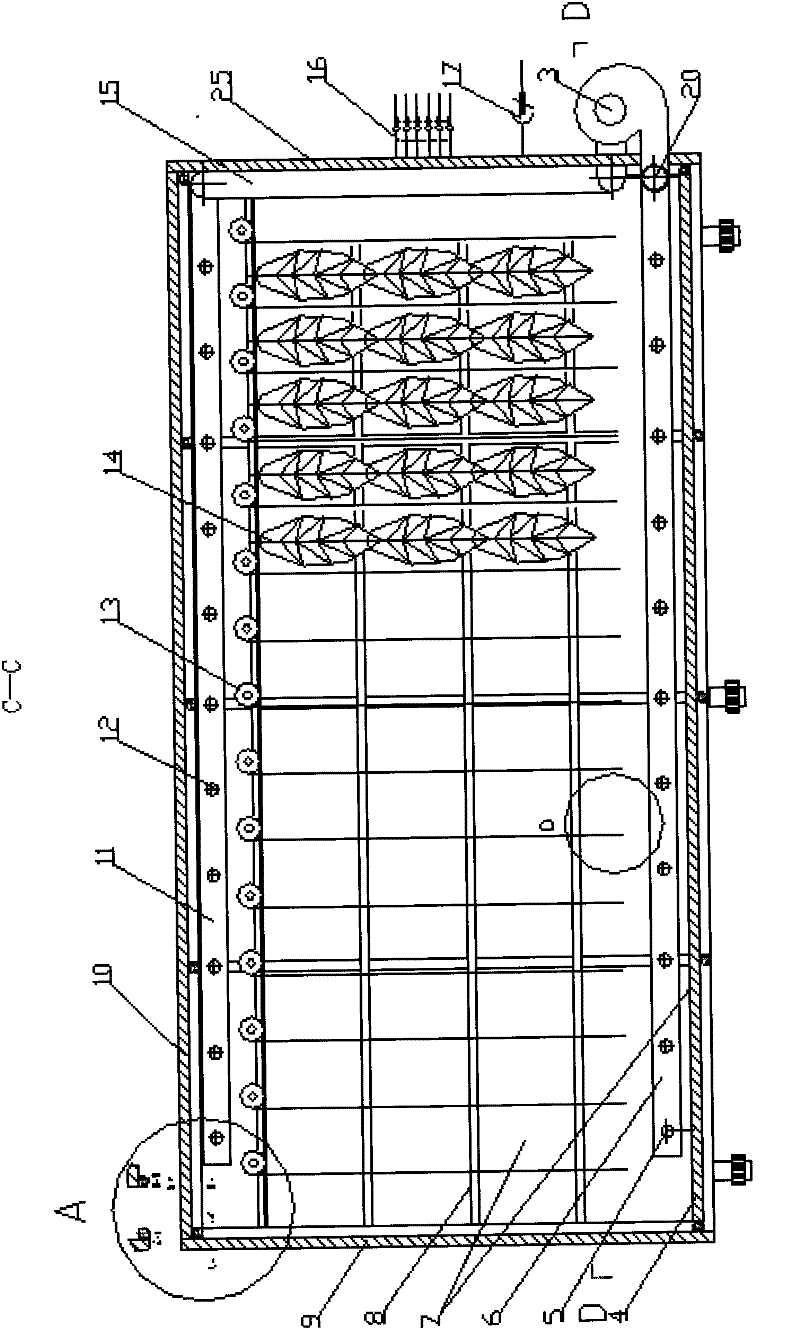

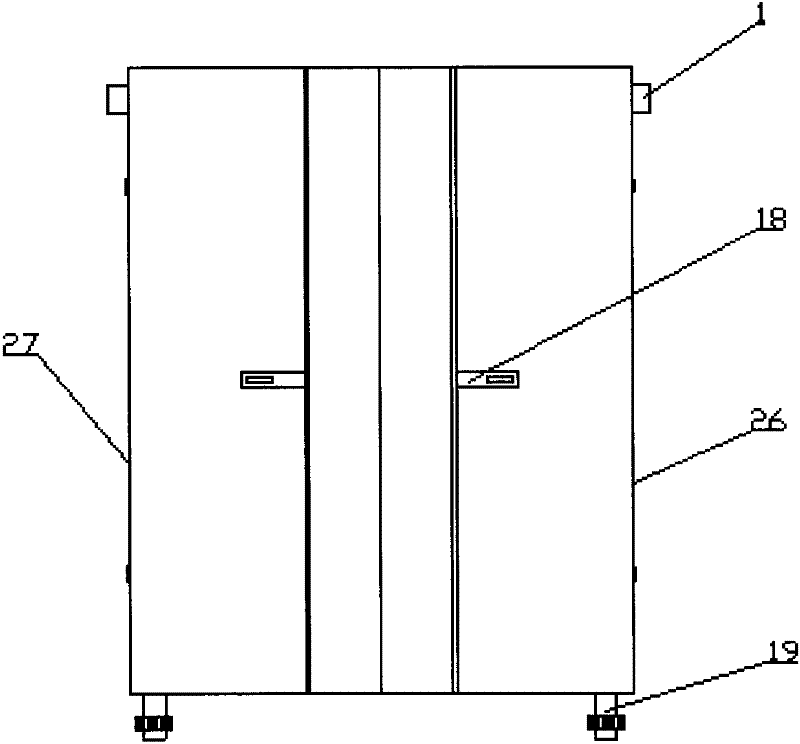

[0010] A specific embodiment of a far-infrared flue-cured tobacco device is: the far-infrared flue-cured tobacco device of the present invention is composed of side surfaces 26 and 27, a top surface 10, a bottom surface 4, an openable and closable end surface 9, and a fixed end surface 25 to form a closed rectangular hexahedron, forming a hexahedron. Each surface is an independent component, and the frame of each component adopts a structural square steel pipe 22, and the frame and the heat preservation component 23 forming a hexahedron of far-infrared tobacco flue-cured equipment are connected with fastening screws 21 to form a hexahedral heat-insulation component of far-infrared tobacco flue-cured equipment It is made of light-duty thermal insulation color steel plate. The side, top, bottom and end faces are connected with setting screws 21 to form an assembly structure. The appearance and internal space of the hexahedron are cuboids, which are similar to each other. The op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com