Method for forging and pressing semi-coupler with large section and high height-diameter ratio by using 31.5 MN of oil press

A semi-coupling and large cross-section technology, which is applied in the field of metal forging, can solve problems such as compaction of difficult central parts, poor grain boundary plasticity, and difficult production, and achieve quality assurance of forgings, simple process, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

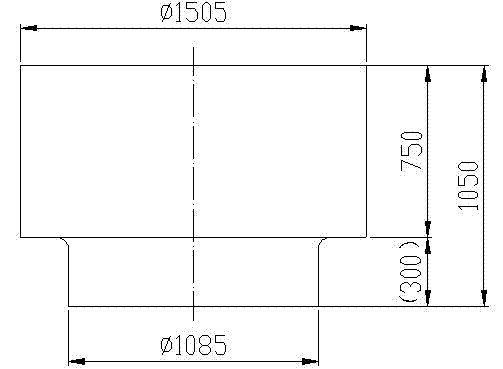

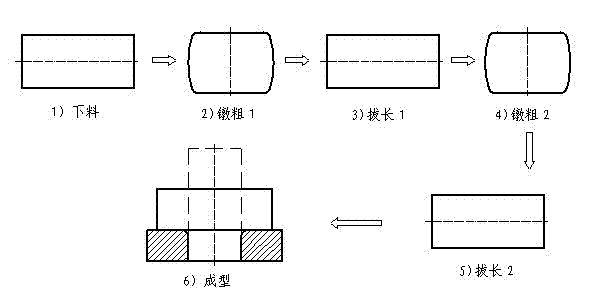

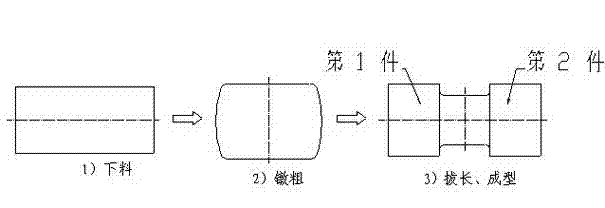

[0024] 1. Original forging process (plan 1)

[0025] 1.1. In the past, the forging method used to produce this type of product was the two-upsetting and two-drawing method, and the process route was: upsetting → drawing out → re-upsetting → re-drawing → partial upsetting forming, see figure 2 . This method not only has complex process, many firing times, high energy consumption, and high production cost, but also the actual production experience and experimental data prove that the quality of the forging cannot be guaranteed obviously by using the two-upsetting and two-drawing process.

[0026] 1.2. On the surface, this forging method is relatively large. For example, if the forging ratio of each upsetting is 2, the total forging ratio after the second upsetting is 2+2=4. However, in actual production, due to the limitation of the forging tonnage of the press, the overall upsetting cannot be in place. The upsetting is completed by the subsequent narrow anvil rotary rolling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com