Turntable inclined scratching type photoelectric automatic particle counter

A particle counting instrument and oblique scraping technology, which is applied in the field of automatic metering, packaging and control of pellets, can solve the problems of large AC resonance noise, no interval, and difficulty in increasing the counting speed of the electromagnet torsional vibrator, and achieve the goal of pellet counting. Low damage rate, accurate and reliable number of grains, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

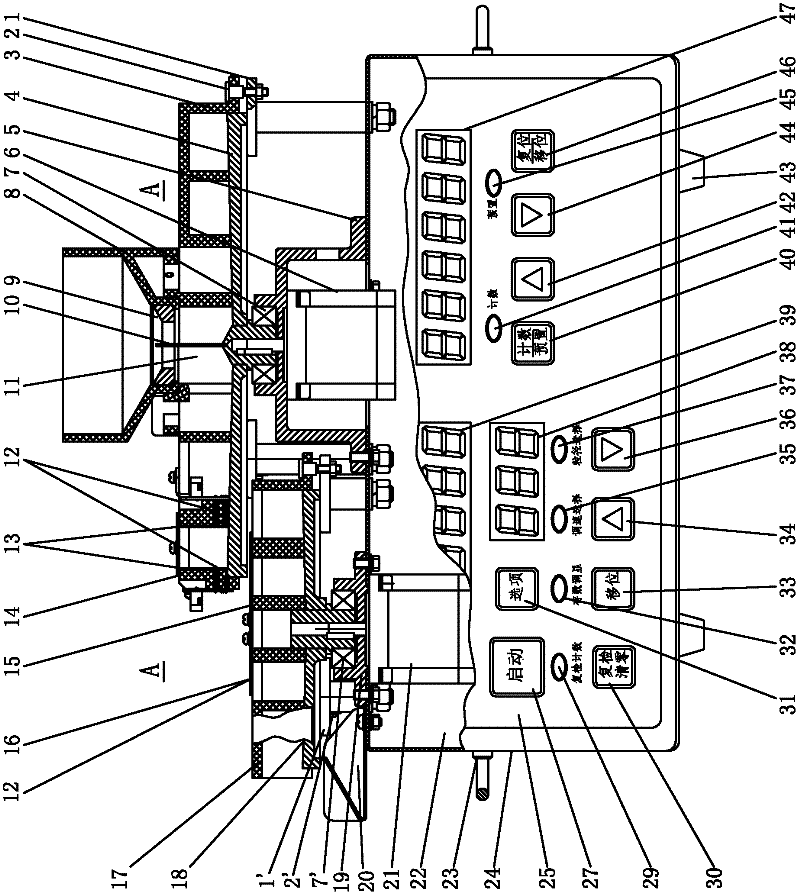

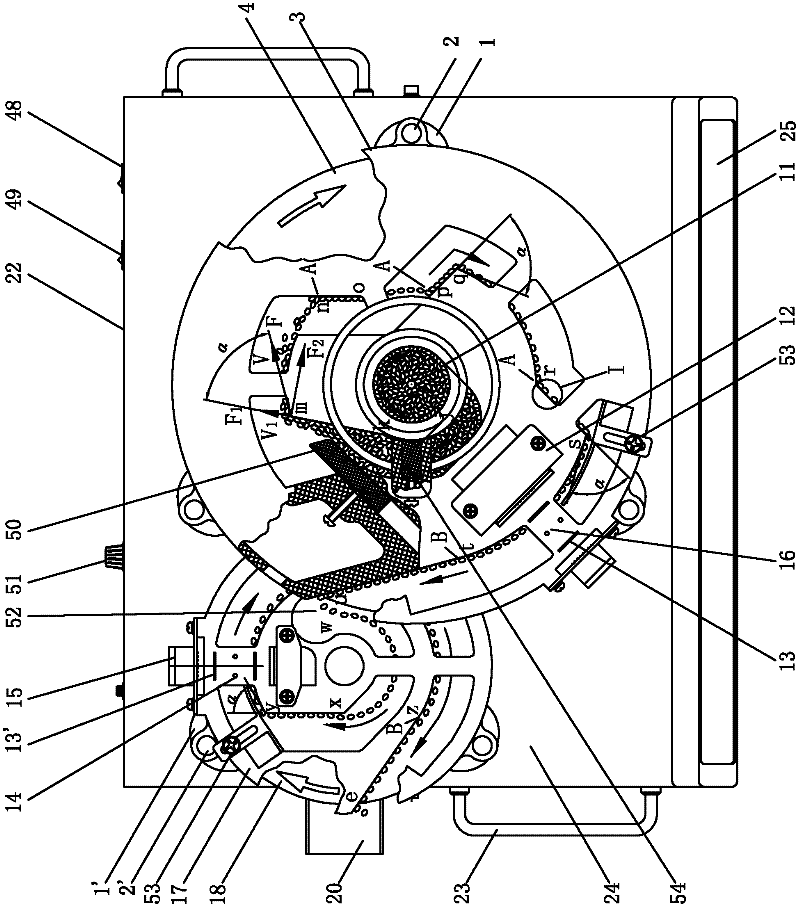

[0049] Such as Figure 1-3 As shown, the present invention is composed of multiple systems, including: a preset counting system, a re-inspection counting system, an electronic control system, and the like.

[0050] Turntable oblique scraping photoelectric automatic particle counting instrument, the particle counting instrument includes:

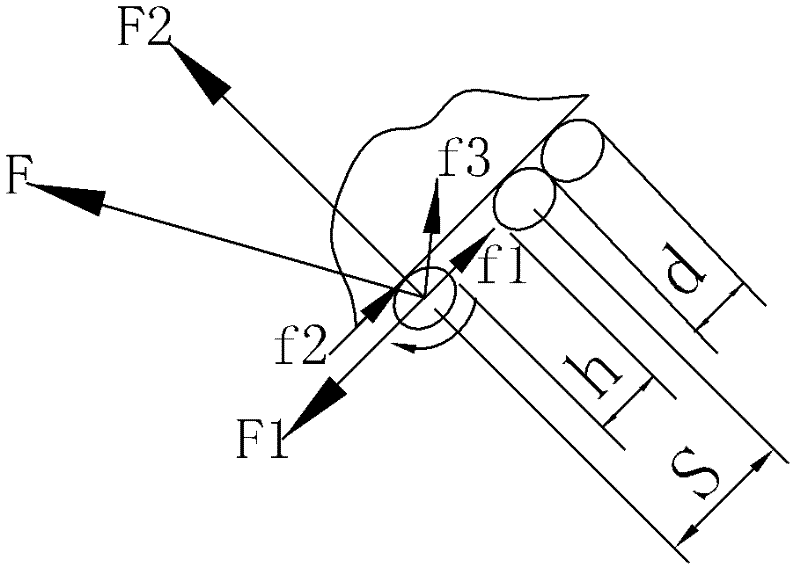

[0051] A. The preset counting system includes a rotary table feeding device, a flow adjustment device, a photoelectric counting sensor device, and a positioning floating device for the feeding tank. The description and working process of each device are as follows:

[0052] 1. Turntable grain supply device, including conical feed cylinder 8, grain supply trough plate 3 set at the bottom of the conical feed cylinder, grain supply turntable 4 set under the grain supply trough plate 3, grain supply motor bearing seat 5 , turntable bearing 7, for grain stepper motor 6. A turntable bearing 7 is installed on the upper part of the grain supply mot...

Embodiment 2

[0104] On the basis of Embodiment 1 of the present invention, an electronic balance is configured again, and this instrument just can become a thousand-grain weight meter or a hundred-grain weight meter. The balance is arranged at the lower end of the grain discharge slide 20, and the grain-loading box is placed on the balance, and the balance is used to weigh the weight of the grains. Example: The preset number is set to 1000, and the number of rapeseed seeds after the actual re-inspection and counting is exactly 1002, which is 3.87 (g) after weighing. From the calculation formula: weight (g) / number of re-inspected grains×1000=thousand grain weight (g / 1000 grains), it can be known that the thousand grain weight of the rapeseed=3.87g / 1002×1000=3.86g / 1000 grains.

Embodiment 3

[0106] The instrument of Embodiment 1 of the present invention is placed on an automatic assembly line to form an automatic packaging device. A control line is drawn out from the numerical control circuit of the instrument to be connected with the automatic assembly line control circuit. Every time a round of preset counting starts, the assembly line is instructed to move, and the sub-packaging container (or other sub-packaging bags, etc.) is moved to the particle discharge slide 20 times and then stops to receive the falling particles. At the beginning of the next round of preset counting, the instruction assembly line will move again, and the next sub-packaging container will be moved to 20 times of the discharge slide to realize automatic sub-packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com