Flexible type radio-frequency coaxial cable of smooth aluminum tube external conductor and production method thereof

A technology of radio frequency coaxial cable and aluminum outer conductor, which is applied in the direction of waveguide, circuit, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

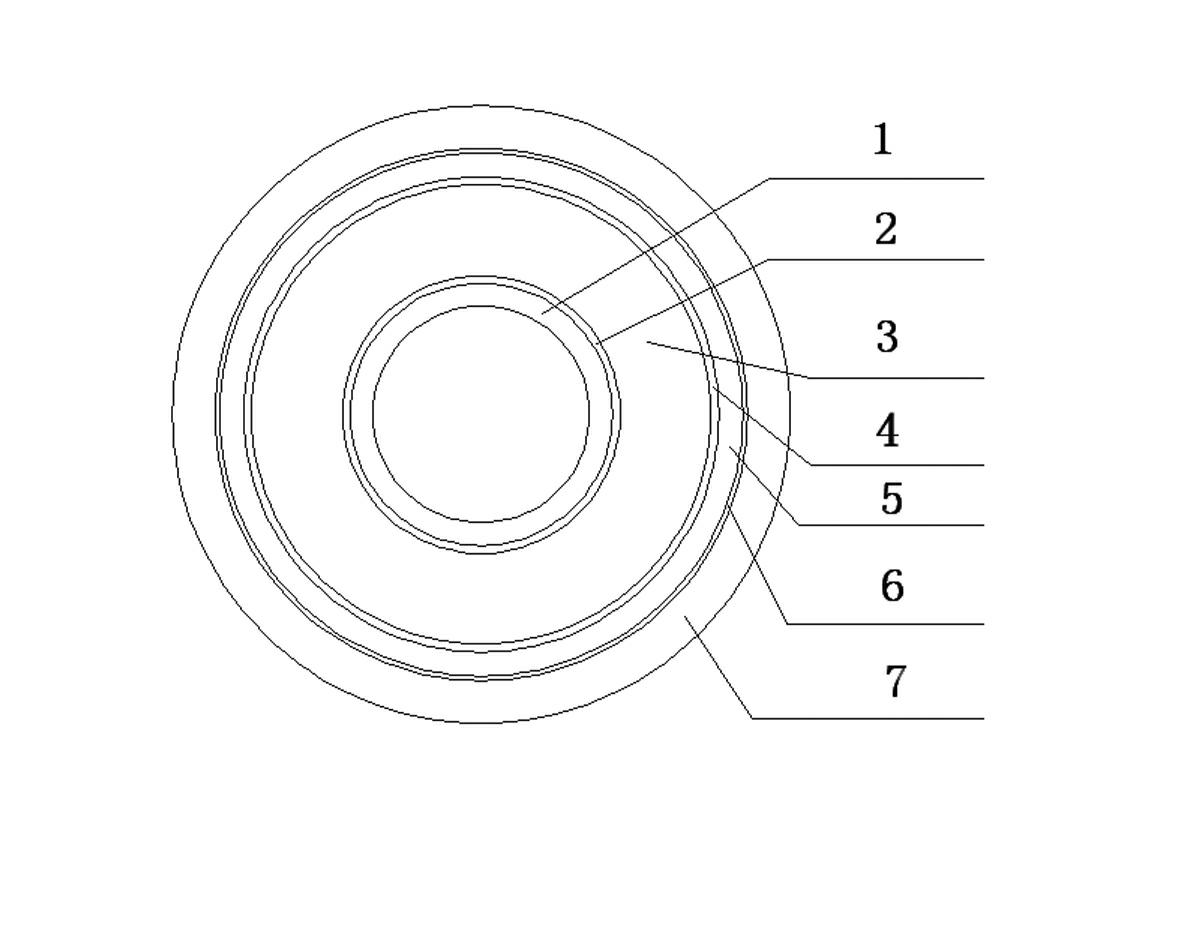

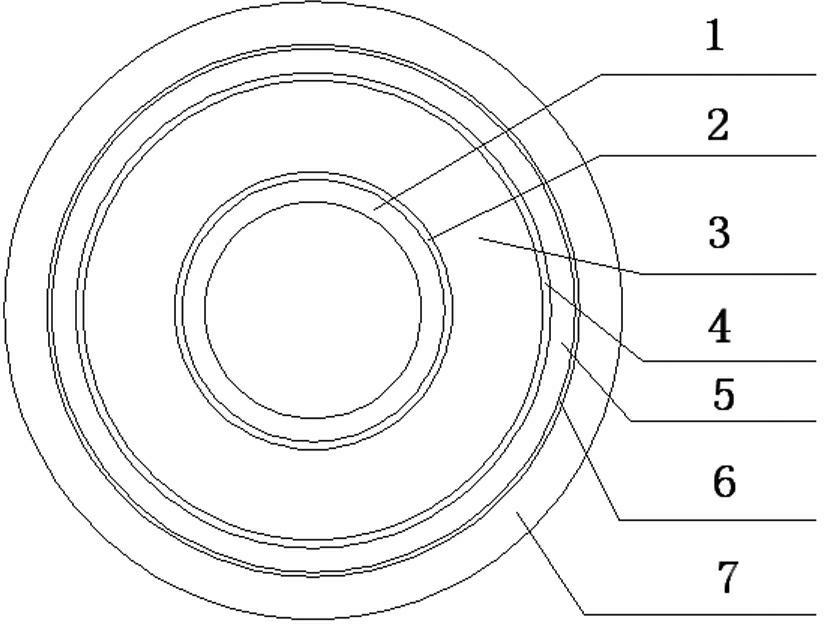

[0044] The 50-25 soft type smooth aluminum tube outer conductor radio frequency coaxial cable of the present invention, 1. includes a smooth tube inner conductor of Φ9.5 mm, an inner skin layer with a thickness of 7.95 mm, a foamed polyethylene insulating layer and an outer skin layer, and 2. a thickness of 0.35 mm mm aluminum strip longitudinal wrapping, argon + helium shielded welding, multi-pass drawing, high-frequency heating, 3. Linear low-density polyethylene sheath. The outer diameter of the outer conductor of the cable is 25.5mm, and the insulating layer is foamed with nitrogen alone, and the foaming degree is 77%.

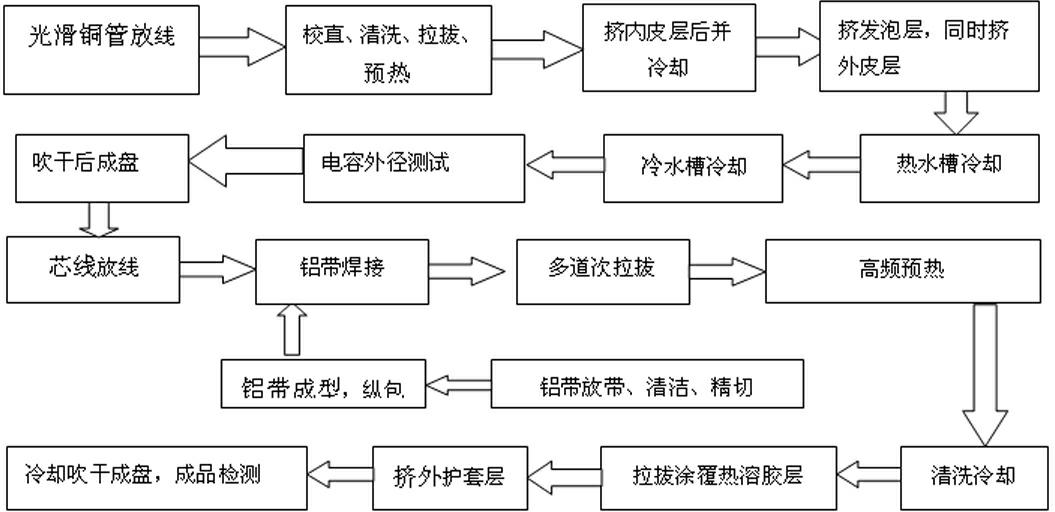

[0045] Manufacturing process flow method of the present invention refers to figure 1 , mainly divided into two parts of production.

[0046] For the production of foamed cable cores, install the inner conductors of smooth copper tubes that meet the requirements on the pay-off rack equipment. After heating, it passes through the inner skin layer of the ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com