High-bending-resistance circuit board for automobile and preparation method of high-bending-resistance circuit board

A circuit board and bending-resistant technology, which is applied in printed circuit manufacturing, circuit substrate materials, printed circuits, etc., can solve the problems of short service life of flexible circuit boards, short service life, and aging of circuit layers, so as to save design area and improve Service life, effect of changing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

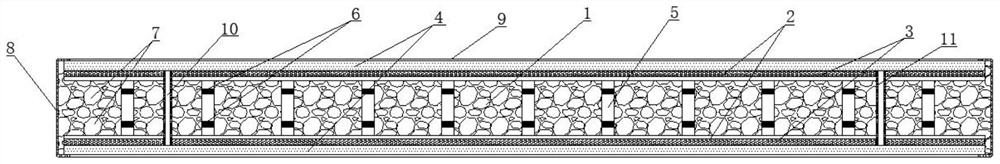

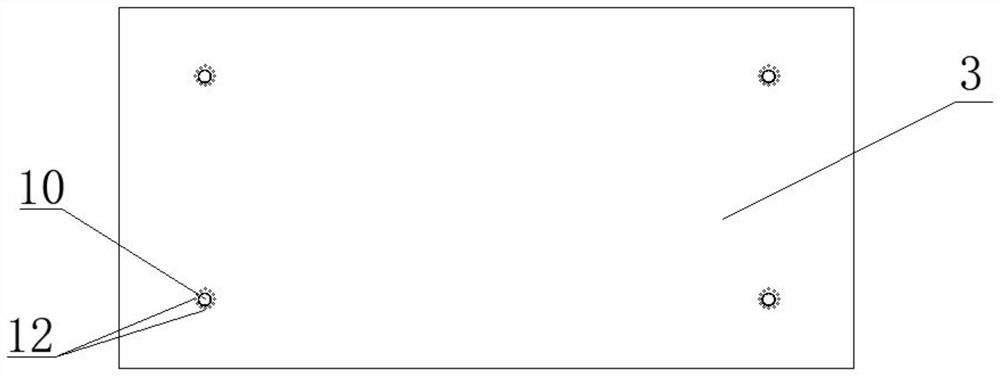

[0032] Such as Figure 1-2 As shown, a circuit board with high bending resistance for automobiles, the circuit board includes a rigid bending-resistant plate 1 arranged in the middle, and a flexible prepreg 2 is attached to the upper and lower outer surfaces of the rigid bending-resistant plate 1, and the flexible prepreg 2 The upper and lower outer surfaces of the honeycomb heat dissipation sheet 3 are attached; the upper and lower outer surfaces of the honeycomb heat dissipation sheet 3 are provided with a flexible copper wire plate 4, and the outer surface of the flexible copper wire plate 4 is provided with a protective film layer 9, and the rigid bending resistant plate 1 Divided into several square bending resistant plates, buffer grooves 5 are arranged between the square bending resistant plates, and elastic connecting ribs 6 are arranged inside the buffer grooves 5.

[0033] Further, the rigid anti-bending plate 1 is provided with air bubble cavities 7 of different siz...

Embodiment 2

[0051] Rigid anti-bending plate 1 is composed of resin glue and organic fiber. The resin glue includes 25% polyimide, 15% polytetrafluoroethylene, 10% MDI modified bromine-free resin, 20% carbon fiber modified high elastic polyethylene, Modified graphene oxide 5%, acetone 20% and 4-methylimidazole 5%.

[0052] Organic fibers include 10% polyester fiber, 10% nylon fiber, 5% polyvinyl formal fiber, 10% polyparaphenylene terephthalamide fiber, 30% polyurethane elastic fiber, 10% polyamide fiber and Carbon fiber modified high elastic polyethylene fiber 25%.

[0053] The elastic connecting rib 6 is made of resin glue and mixed fibers, the resin glue of the elastic connecting rib 6 is the same as that of the rigid anti-bending plate 1, and the mixed fiber includes 15% of 3J9 (2Cr19Ni9Mo) alloy fiber, 30% of braided carbon fiber and modified carbon fiber High elastic polyethylene fiber 55%.

[0054] A method for preparing a high bending resistance circuit board for automobiles, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com