Method for preparing pore gradient metal or alloy material by microwave sintering

A technology of microwave sintering and alloy materials, which is applied in the field of preparing pore gradient metal or alloy materials, can solve the problems that have not been reported, and achieve the effects of easy process, cost reduction and enhanced microwave absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] ① Mill the W powder with a purity greater than 99.5% and an average particle size of 1.98 μm at a ball-to-material ratio of 1:1 and a rotational speed of 150 rpm for 6 hours in a stainless steel ball mill cylinder, take it out and press it into a compact;

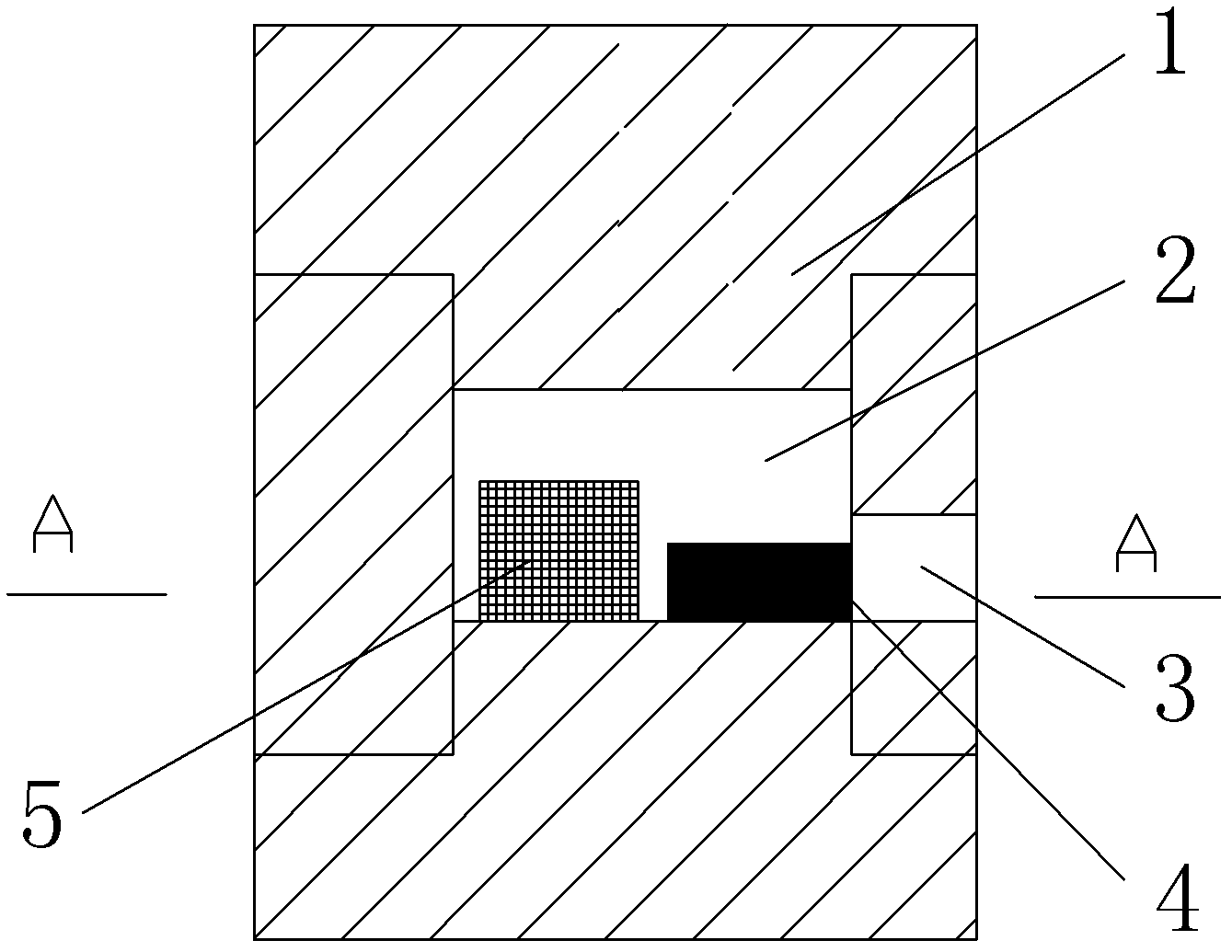

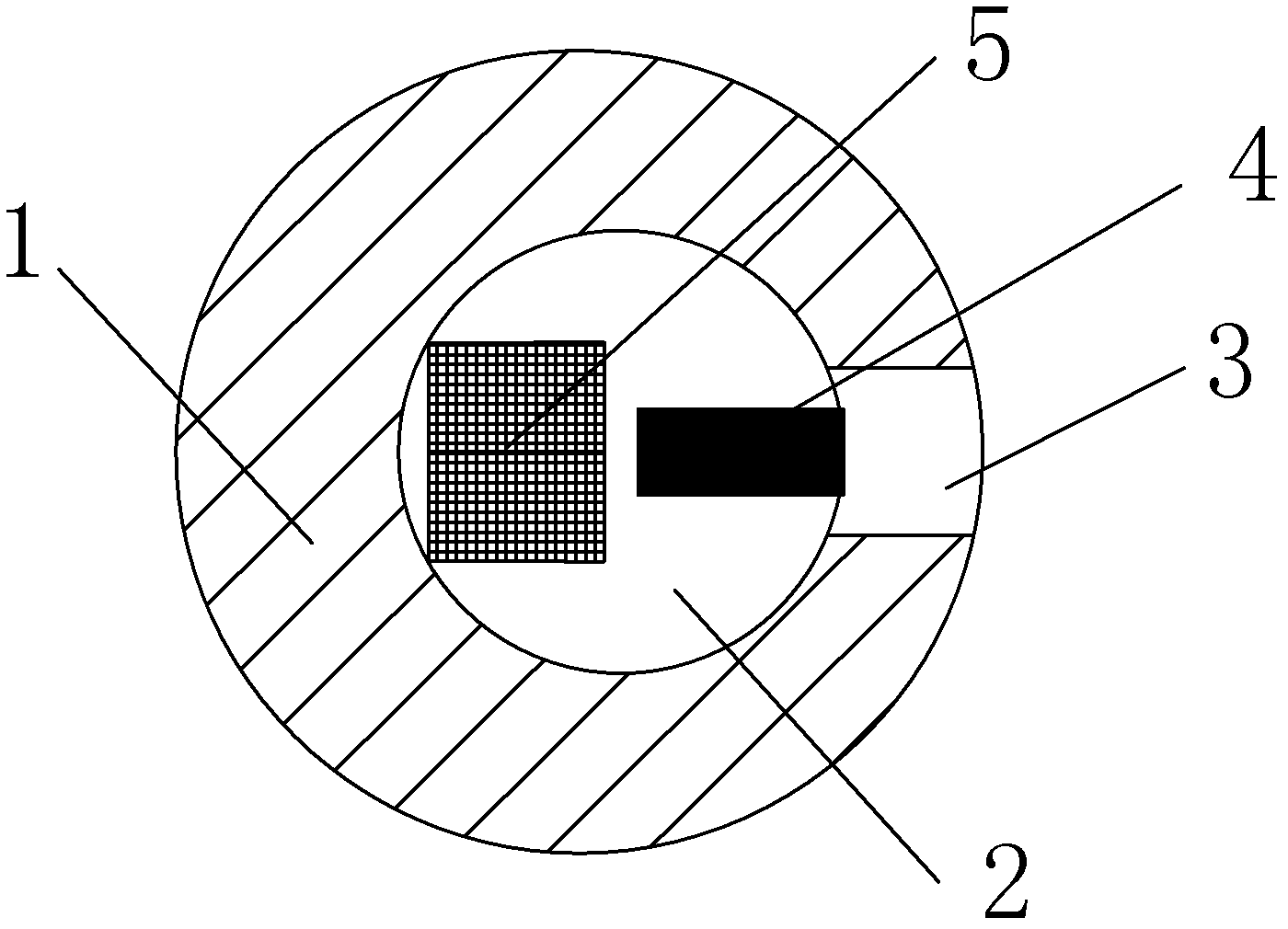

[0033] ②Alumina fiber is used as the insulation body, and SiC is added as the auxiliary heating material in the insulation body. The insulation structure is shown in the figure, and the amount of SiC as the auxiliary heating material is 300g.

[0034] ③The compact is placed in the sintering cavity and placed in a microwave high-temperature furnace;

[0035] ④Use a vacuum pump to exhaust the air in the microwave oven cavity, and then inject N 2 Atmosphere protection; adjust the output power of the microwave high-temperature furnace, heat up to 1000°C at a heating rate of 5°C / min, then adjust the microwave input power to make the heating rate reach 25°C / min, and the temperature reaches 1450°C, turn off the microwave so...

Embodiment 2

[0038] ① Mix W powder with a purity greater than 99.5% and an average particle size of 1.98 μm, Cu powder with a purity greater than 99.5% and an average particle size of 9 μm, and Ni powder with a purity greater than 99.5% and an average particle size of 2.3 μm, according to the mass percentage of 95W-4Cu-1Ni, With a ball-to-material ratio of 1:1 and a rotational speed of 150rpm, ball mill in a stainless steel ball mill cylinder for 6 hours, take it out and press it into a compact;

[0039] ②Alumina fiber is used as the insulation body, and SiC is added as the auxiliary heating material in the insulation body. The insulation structure is shown in the figure, and the amount of SiC as the auxiliary heating material is 300g.

[0040] ③The compact is placed in the sintering cavity and placed in a microwave high-temperature furnace;

[0041] ④Use a vacuum pump to exhaust the air in the microwave oven cavity, and then inject N 2 Atmosphere protection; adjust the output power of th...

Embodiment 3

[0044] ① Mix W powder with a purity greater than 99.5% and an average particle size of 1.98 μm, Ni powder with a purity greater than 99.5% and an average particle size of 2.3 μm, and Fe powder with a purity greater than 99.5% and an average particle size of 2.3 μm, according to the mass percentage of 90W-7Ni-3Fe , with a ball-to-material ratio of 1:1 and a rotating speed of 150rpm, mixed in a stainless steel ball mill for 6 hours, and pressed into a compact after being taken out;

[0045]②Alumina fiber is used as the insulation body, and SiC is added as the auxiliary heating material in the insulation body. The insulation structure is shown in the figure, and the amount of SiC as the auxiliary heating material is 300g.

[0046] ③The compact is placed in the sintering cavity and placed in a microwave high-temperature furnace;

[0047] ④Use a vacuum pump to exhaust the air in the microwave oven cavity, and then inject H 2 Atmosphere protection; adjust the output power of the mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com