Precharge method of lithium ion batteries

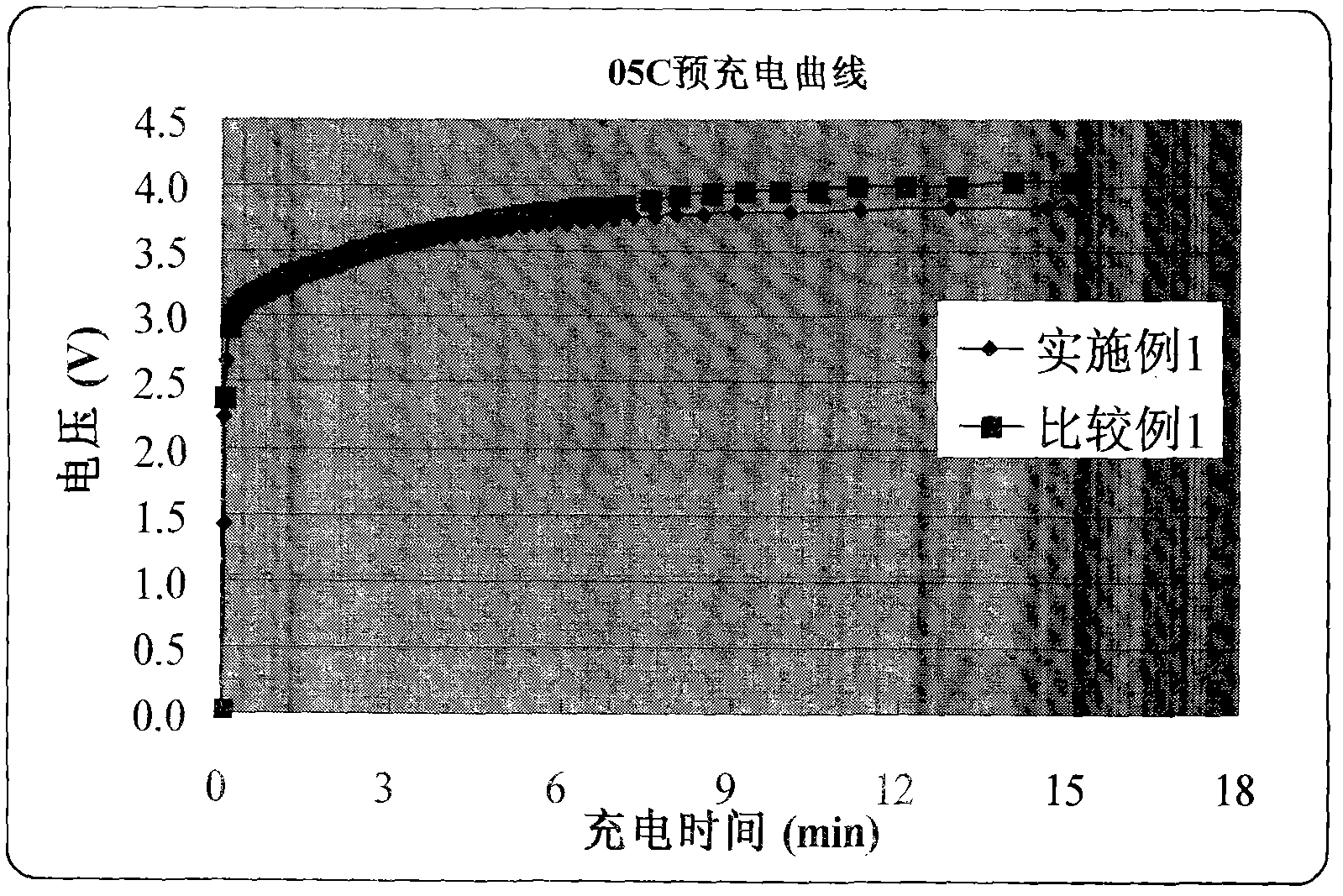

A lithium-ion battery and pre-charging technology, which is applied in the field of lithium-ion batteries, can solve the problems of poor low-temperature performance of the battery cell, unsatisfactory charging effect, and unsolved polarization problems, so as to achieve good electrical performance, eliminate the problem of uneven charging, Effect of Shortening Precharge Time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

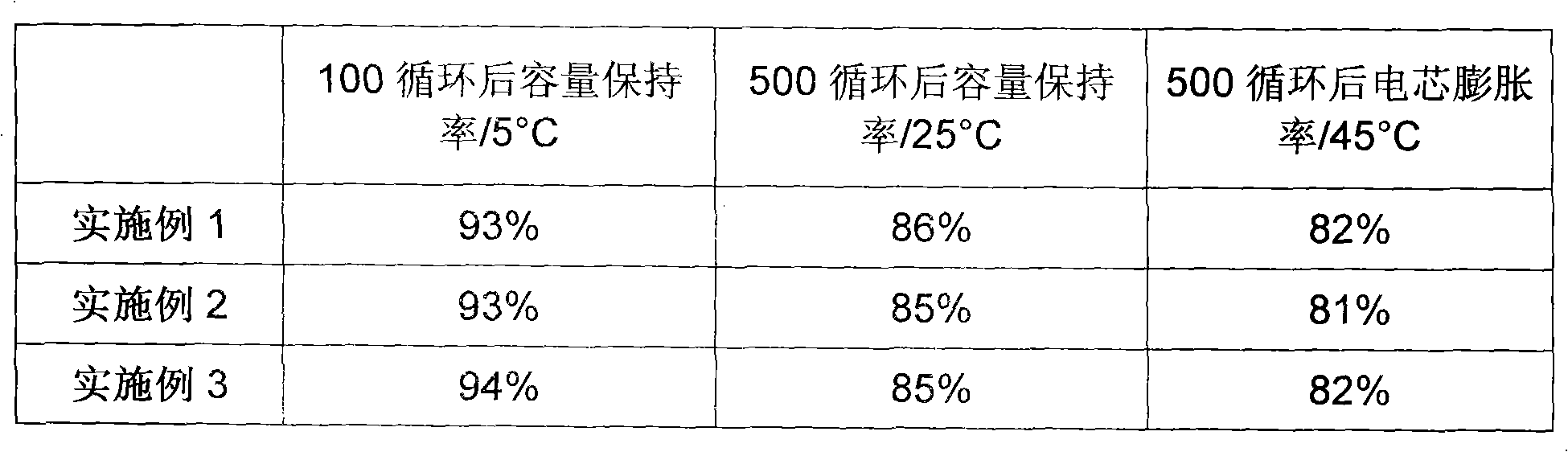

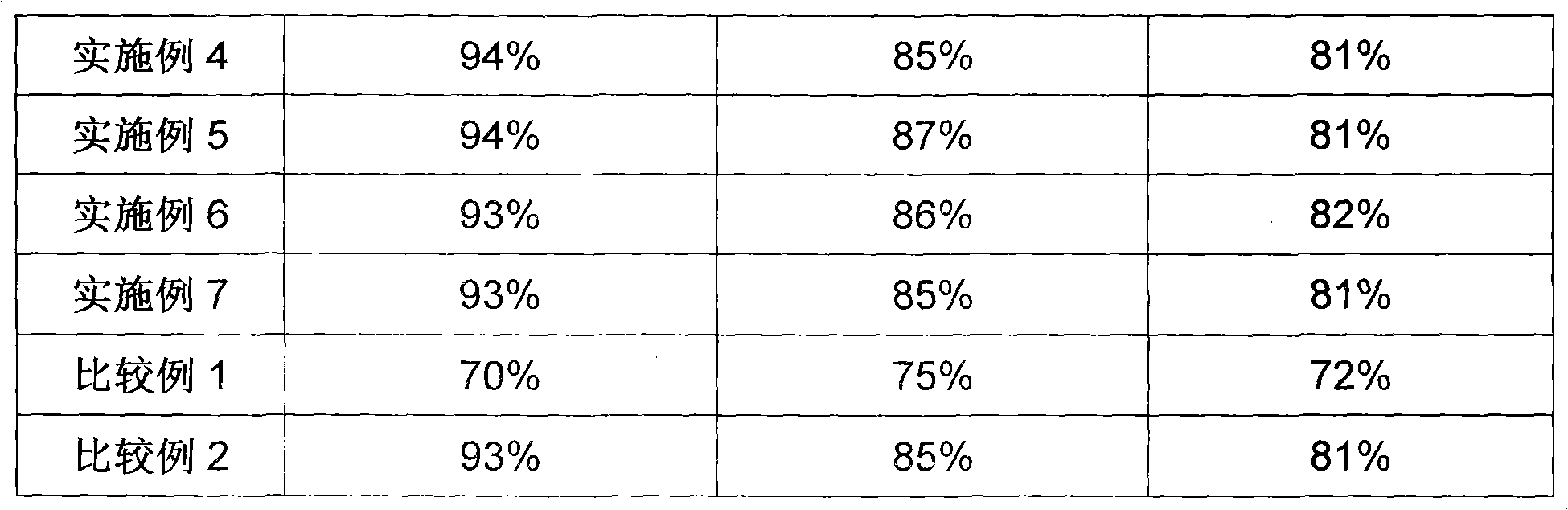

Embodiment 1

[0021] The positive and negative electrode sheets and separators made of lithium cobalt oxide as the positive electrode active material and graphite as the negative electrode active material are made into bare cells by lamination or winding, and then the cells are put into the packaging case and inserted into the Inject 1mol / L LiPF 6 / (EC+PC+DEC) electrolyte to make a battery. Wherein the volume ratio of ethylene carbonate (EC), propylene carbonate (PC) and diethyl carbonate (DEC) is 1:1:1. Put the prepared battery into two flat plates and apply a pressure of 0.8Mpa, charge it with a current of 0.5C for 15min at an ambient temperature of 45°C, the pre-charged amount is 12.5% of the total electricity of the cell, and form an SEI film on the surface of the negative electrode. Afterwards, it is vacuum-packed, and then the capacity and cycle tests are carried out. The test contents are shown in Table 1.

Embodiment 2

[0023] The positive and negative electrode sheets and separators made of lithium cobalt oxide as the positive electrode active material and graphite as the negative electrode active material are made into bare cells by lamination or winding, and then the cells are put into the packaging case and inserted into the Inject 1mol / L LiPF 6 / (EC+PC+DEC) electrolyte to make a battery. Wherein the volume ratio of ethylene carbonate (EC), propylene carbonate (PC) and diethyl carbonate (DEC) is 1:1:1. Put the prepared battery into two flat plates and apply a pressure of 1.2Mpa, charge with a current of 0.3C for 30min at an ambient temperature of 23°C, the pre-charged amount is 15% of the total electricity of the cell, and an SEI film is formed on the surface of the negative electrode. Afterwards, it is vacuum-packed, and then the capacity and cycle tests are carried out. The test contents are shown in Table 1.

Embodiment 3

[0025] The positive and negative electrode sheets and separators made of lithium manganate as the positive electrode active material and graphite as the negative electrode active material are made into bare cells by lamination or winding, and then the cells are put into the packaging case and inserted into the Inject 1mol / L LiPF 6 / (EC+PC+DEC) electrolyte to make a battery. Wherein the volume ratio of ethylene carbonate (EC), propylene carbonate (PC) and diethyl carbonate (DEC) is 1:1:1. Put the prepared battery into two flat plates and apply a pressure of 0.01Mpa, and charge it with a current of 0.05C for 120min at an ambient temperature of 10°C. Afterwards, it is vacuum-packed, and then the capacity and cycle tests are carried out. The test contents are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com