Method for releasing electric quantity of high-voltage bus capacitor of car motor driver

A technology of motor drivers and high-voltage busbars, which is applied in the direction of control drives, electric vehicles, vehicle components, etc., to achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Combine below figure 1 and figure 2 , the present invention is further described:

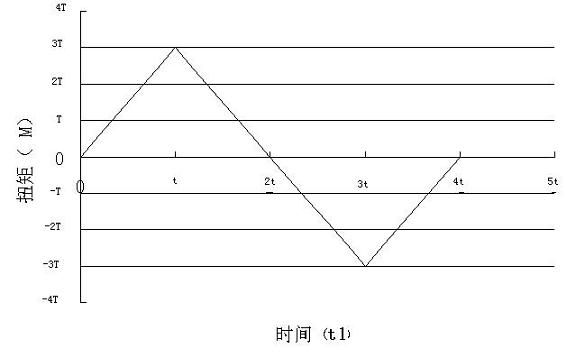

[0027] Such as figure 1 As shown, the torque time loading function is:

[0028] 1. M=3T / t*t 1 , where 0≤ t 1 1 for time;

[0029] 2. M=-3T / t*t 1 +6T, where t≤ t 1 1 for time;

[0030] 3. M=3T / t*t 1 -12T, where 3t≤t 1 1 for time.

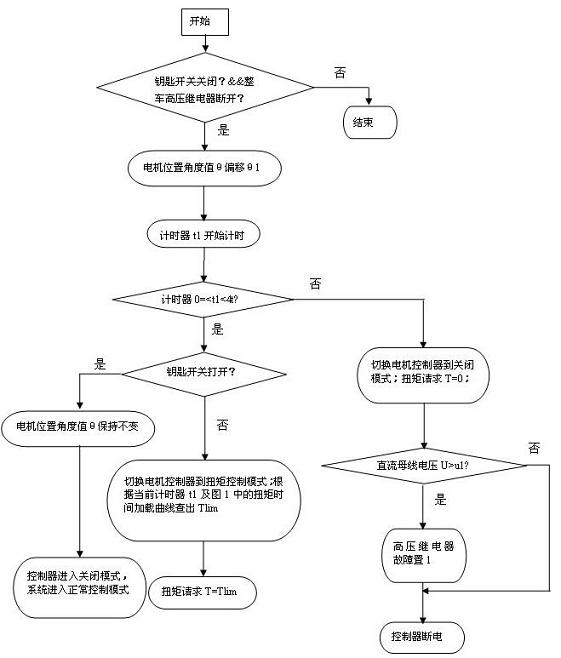

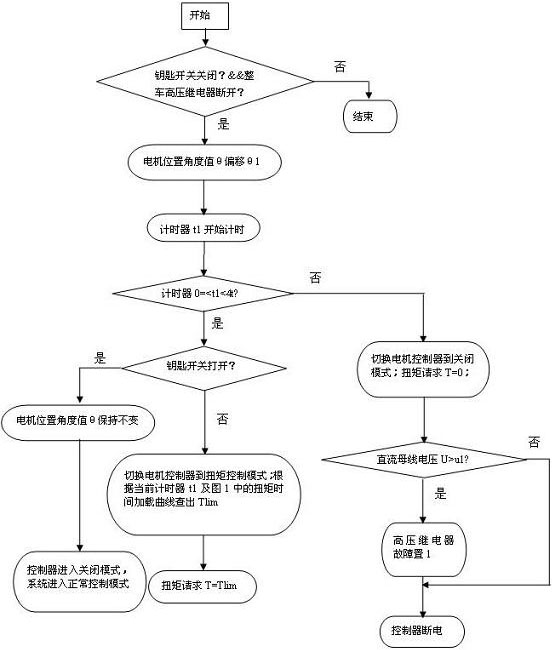

[0031] Such as figure 2 As shown, the power discharge method of the high-voltage bus capacitor of the vehicle motor driver is as follows:

[0032] When the vehicle key switch is turned off and the vehicle high-voltage relay is off, the motor controller enters the active discharge program, otherwise the motor controller works normally;

[0033] The motor position angle value θ offset by the motor position sensor sampled each time is θ 1 Time;

[0034] The motor controller enters the active discharge program, and the timer t 1 start the timer;

[0035] When timer 0 ≤ t 1 When 1 and torque time loading function to get , and make the requested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com