Method for manufacturing cured product of thermosetting resin composition and cured product obtained thereby

A technology of resin composition and cured products, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device components, electrical components, etc., to achieve excellent heat resistance and curing properties, and excellent long-term heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

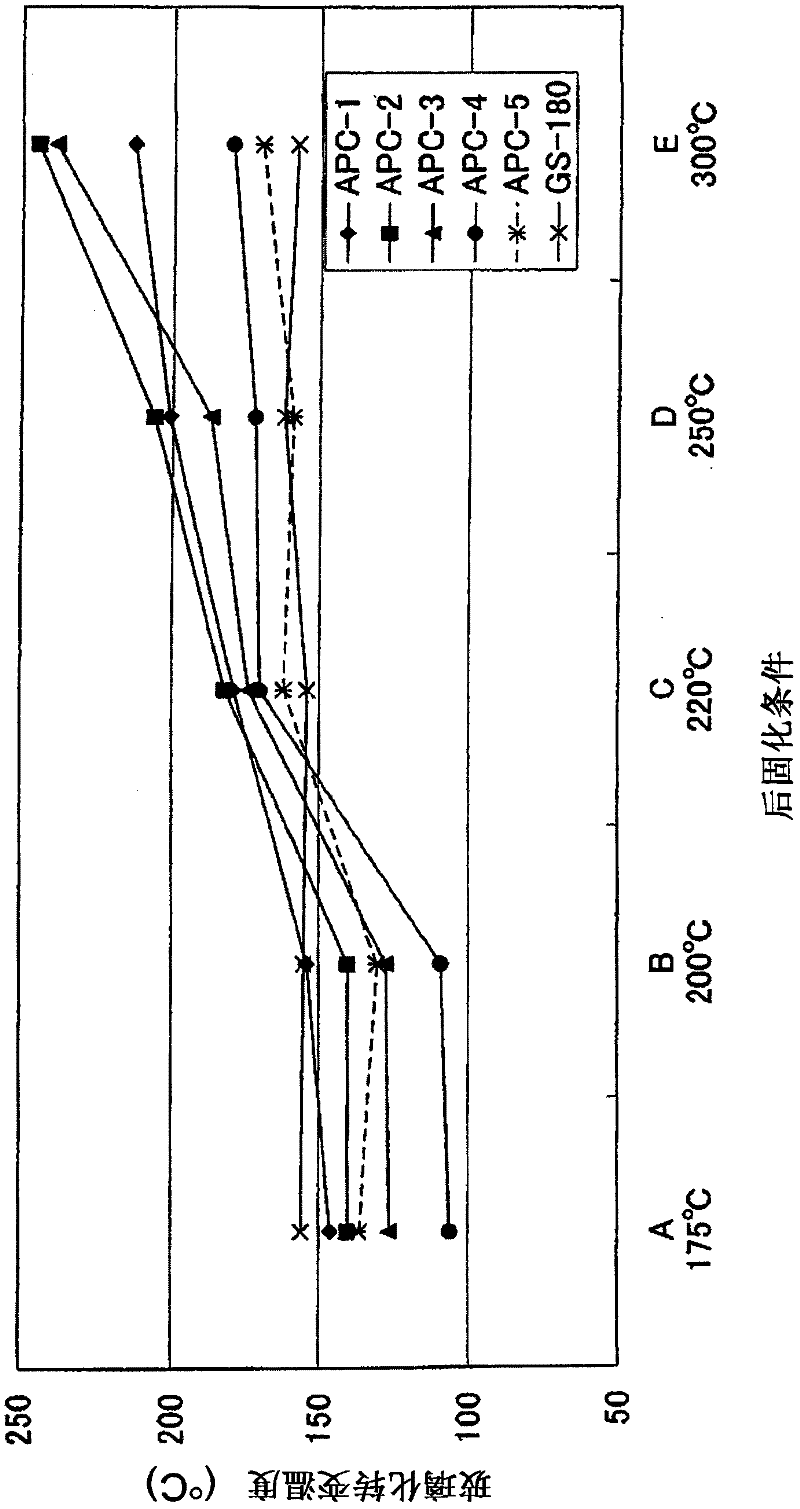

[0060] Examples and comparative examples of the present invention will be described below. However, the present invention should not be construed as being limited to these Examples. Incidentally, "parts" and "%" in the examples are defined as "parts by weight" and "% by weight", respectively, unless otherwise specified.

[0061] First, before preparing a thermosetting resin composition, an allylated phenolic resin was synthesized (Synthesis Examples A-1 to A-5).

Synthetic example A-1

[0063]p-phenolic resin (GS-180, manufactured by Gunei Chemical Industry Co., Ltd., phenol equivalent: 105 g / eq.) (105 parts), 181.5 parts of allyl bromide (produced by Tokyo Chemical Tokyo Chemical Industry Co., Ltd.), 207.3 parts of potassium carbonate (manufactured by Wako Pure Chemical Industries, Ltd.), and 500 parts of acetone (manufactured by Wako Pure Chemical Industries, Ltd. Co., Ltd.) were mixed, and refluxed for 24 hours under heating in a nitrogen stream. After cooling to room temperature (25° C.), filtration and concentration were performed, and 400 parts of ethyl acetate (manufactured by Wako Pure Chemical Industries, Ltd.) was added to the residue, followed by 200 parts of a 5% hydrochloric acid solution diluted with distilled water ( manufactured by Wako Pure Chemical Industries, Ltd.) and washed once with 200 parts of distilled water. Thereafter, the organic layer was extracted and dried with magnesium sulfate (manufactured by Wako Pure Chemical Industries, L...

Synthetic example A-2

[0065] p-phenolic resin (GS-180, manufactured by Qunei Chemical Industry Co., Ltd., phenol equivalent: 105 g / eq.) (105 parts), 90.7 parts of allyl bromide (manufactured by Tokyo Chemical Industry Co., Ltd.), 138.2 parts of potassium carbonate (manufactured by Wako Pure Chemical Industries, Ltd.) and 500 parts of acetone (manufactured by Wako Pure Chemical Industries, Ltd.) were mixed, and refluxed under heating in a nitrogen stream for 24 hours. After cooling to room temperature (25° C.), filtration and concentration were performed, and 400 parts of ethyl acetate (manufactured by Wako Pure Chemical Industries, Ltd.) was added to the residue, followed by 200 parts of a 5% hydrochloric acid solution diluted with distilled water ( manufactured by Wako Pure Chemical Industries, Ltd.) and washed once with 200 parts of distilled water. Thereafter, the organic layer was extracted and dried with magnesium sulfate (manufactured by Wako Pure Chemical Industries, Ltd.), followed by filtr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com