Liquid phase chromatography analysis method for active ingredient content of crude product M

A technology of liquid chromatography analysis and high performance liquid chromatography, which is applied in the direction of analyzing materials, measuring devices, and material separation, and can solve problems such as unclear reaction mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

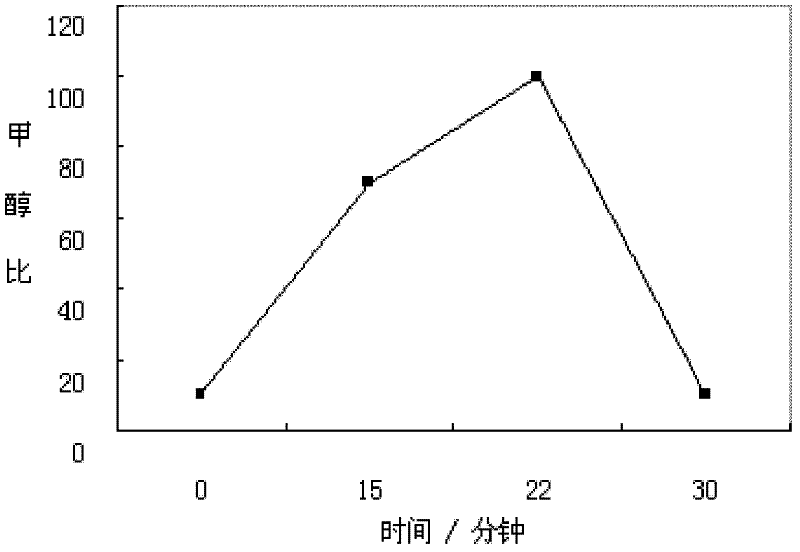

[0010] Use a high-angle weighing bottle to weigh 25 mg of MBT sample, add 10 ml of methanol solution to it, put it in an ultrasonic cleaner and vibrate for 5 minutes, take it out and transfer it to a 250 ml volumetric flask, dilute to the mark with methanol, shake well, and filter to configure 0.1 mg / mL solution; the column temperature is kept at 20°C, the liquid chromatography is a VWD detector, the column model is EXTEND-C18, the liquid chromatography uses water and methanol as the mobile phase, the flow rate is 1ml / min, and the wavelength of the VWD detector is 254nm , use a micro injector to inject 5 μl of sample into the liquid chromatography, and the gradient program is: when the injection time is 0 minutes, the proportion of water in the mobile phase is 90%, and the proportion of methanol is 10%; The proportion of water in the middle is 30%, and the proportion of methanol is 70%; in 22 minutes, the proportion of water in the mobile phase is 0%, and the proportion of meth...

example 2

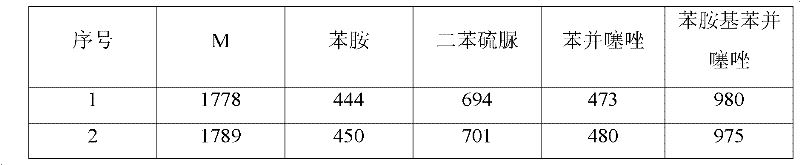

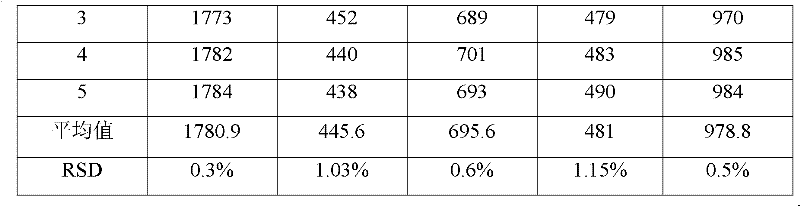

[0015] Weigh 50 mg of MBT sample with a high-angle weighing bottle, add chromatographically pure methanol solution into it, put it in an ultrasonic cleaner and vibrate for 10 minutes, take it out and transfer it to a 250ml volumetric flask, dilute to the mark with methanol, shake well, and filter to configure 0.2mg / mL solution; keep the room temperature at 23°C, use water and methanol as the mobile phase in liquid chromatography, the flow rate is 1ml / min, the wavelength of the VWD detector is 254nm, inject 5μl of sample into the liquid chromatography with a micro injector, the gradient The program is: when the injection time is 0 minutes, the proportion of water in the mobile phase is 90%, and the proportion of methanol is 10%; at 15 minutes, the proportion of water in the mobile phase is 30%, and the proportion of methanol is 70%; 22 At 30 minutes, the proportion of water in the mobile phase was 90%, and the proportion of methanol was 10%. Parallel samples were performed 5 ti...

example 3

[0017] Use a high-angle weighing bottle to weigh 125 mg of MBT sample, add 100 ml of methanol solution to it, put it in an ultrasonic cleaner and vibrate for 20 minutes, take it out and transfer it to a 250 ml volumetric flask, dilute to the mark with methanol, shake well, and filter to configure 0.5 mg / mL solution; keep the room temperature at 27°C, use water and methanol as the mobile phase in liquid chromatography, the flow rate is 1.0ml / min, and the wavelength of VWD detector is 254nm. The program is: when the injection time is 0 minutes, the proportion of water in the mobile phase is 900%, and the proportion of methanol is 10%; at 15 minutes, the proportion of water in the mobile phase is 30%, and the proportion of methanol is 70%; 22 At 30 minutes, the proportion of water in the mobile phase was 90%, and the proportion of methanol was 10%. Parallel samples were performed 5 times with good repeatability. The above effective substances are quantified, and their purity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com