Manufacturing method of N-type radio frequency lateral double-diffused metal-oxide semiconductor (LDMOS)

A manufacturing method, N-type technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems affecting device breakdown characteristics, breakdown voltage drop, etc., to improve breakdown characteristics, increase process costs, Adjustable and adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

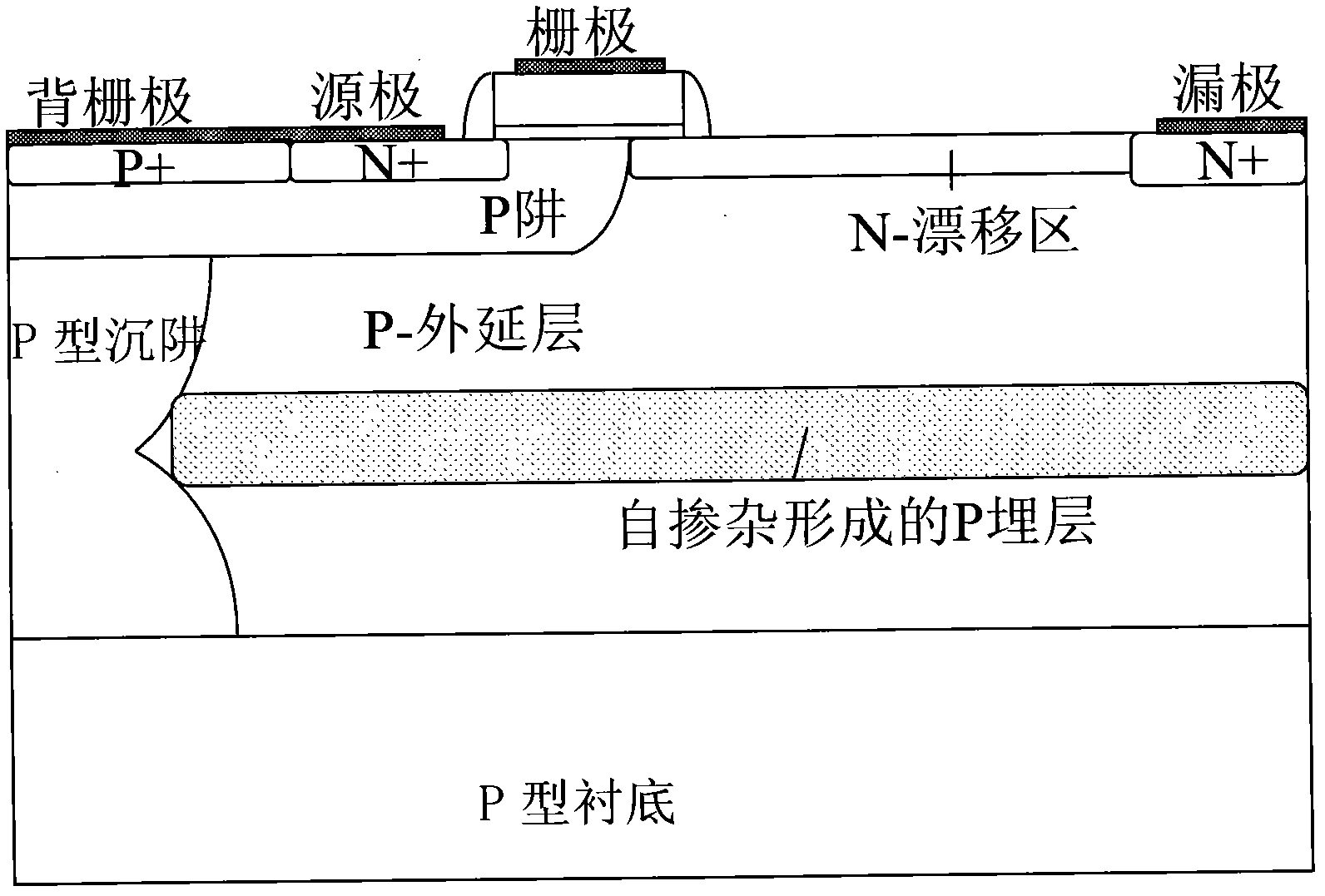

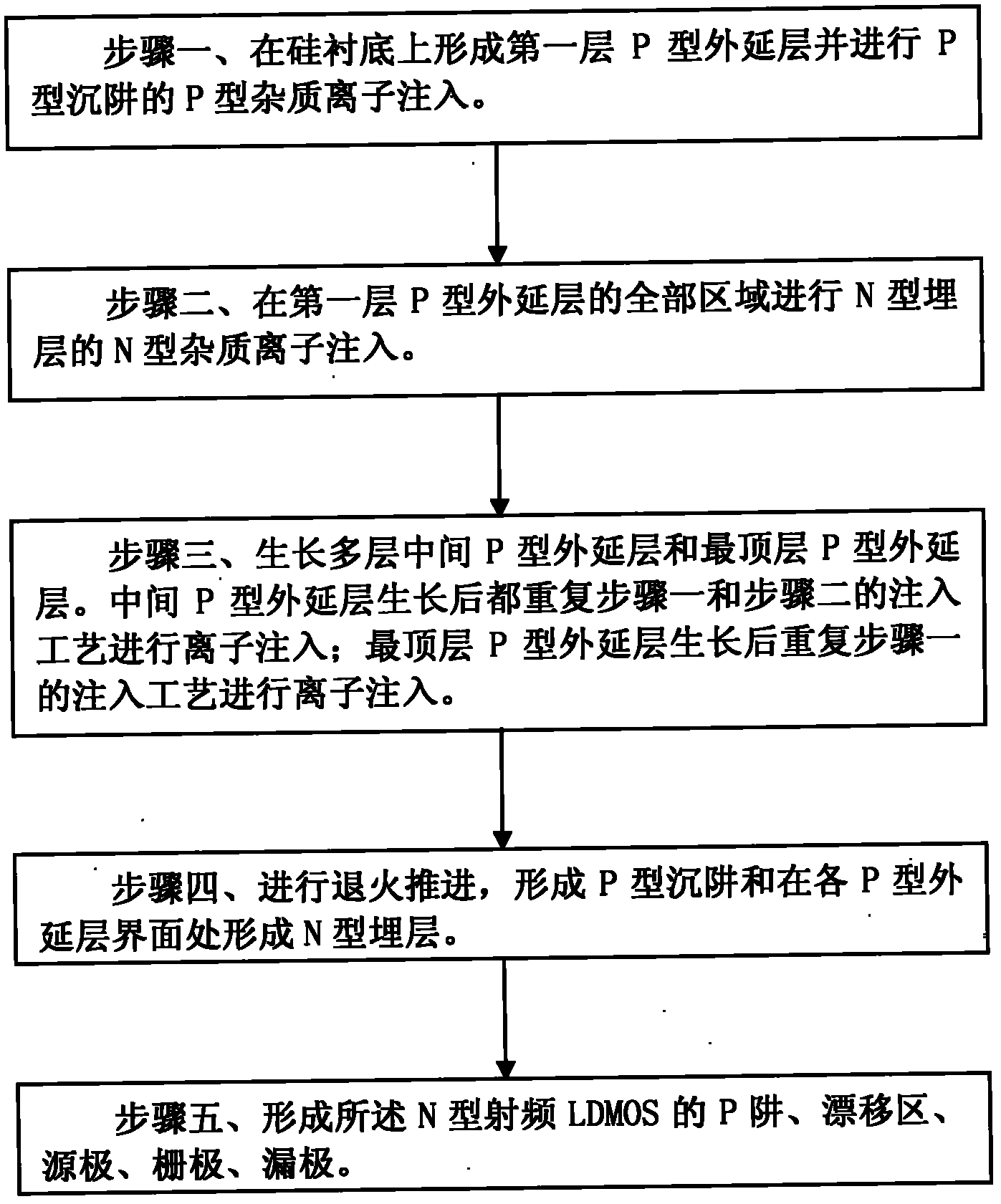

[0017] Such as figure 2 Shown, is the flow chart of the manufacturing method of radio frequency LDMOS of the present invention; As Figure 3 ~ Figure 7 As shown, it is a device schematic diagram of each step in the manufacturing method of a radio frequency LDMOS according to the embodiment of the present invention. The manufacturing method of the radio frequency LDMOS of the embodiment of the present invention comprises the following steps:

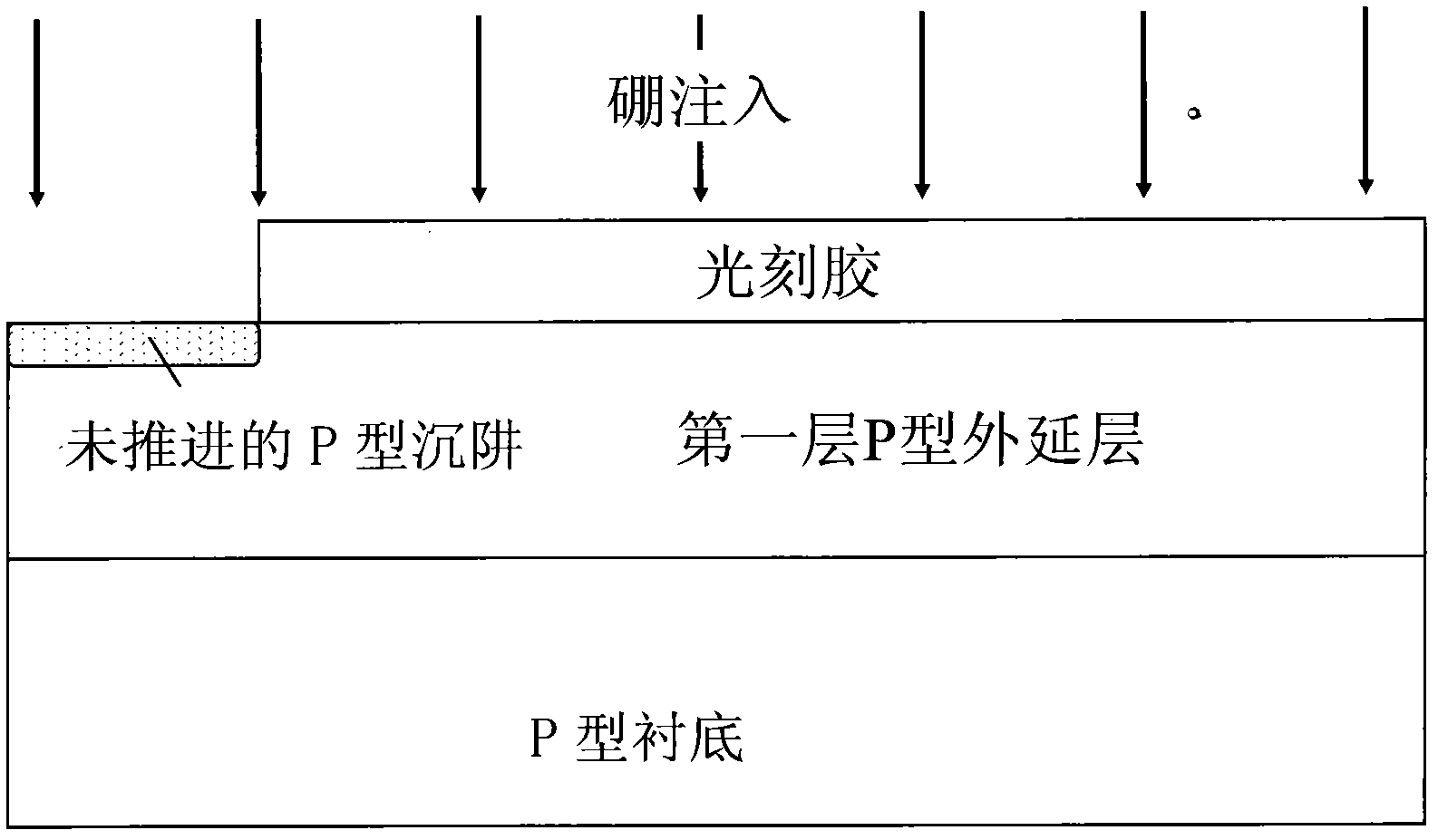

[0018] Step 1, such as image 3 As shown, the first layer of P-type epitaxial layer is formed on a heavily doped P-type silicon substrate, and the P-type sinking well is formed in the region of the first layer of P-type epitaxial layer. Type impurity ion implantation forms a non-propelled P-type sink well. The doping impurity of the first P-type epitaxial layer is boron, and the impurity body concentration is 1.0E14cm -3 ~1.0E15cm -3 . The region of the P-type sink well is defined by photoresist. The process conditions of the P-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com