Vacuum pouring method for gypsum mold high-precision casting of aluminum and magnesium alloy

A technology of vacuum pouring and precision casting, which is applied in the direction of casting molding equipment, cores, casting molds, etc., to achieve the effects of short time, improved casting quality and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: It is required to adopt gypsum mold precision casting technology to cast a bracket for an aircraft, and its size is 400mm long, 250mm wide and 300mm high.

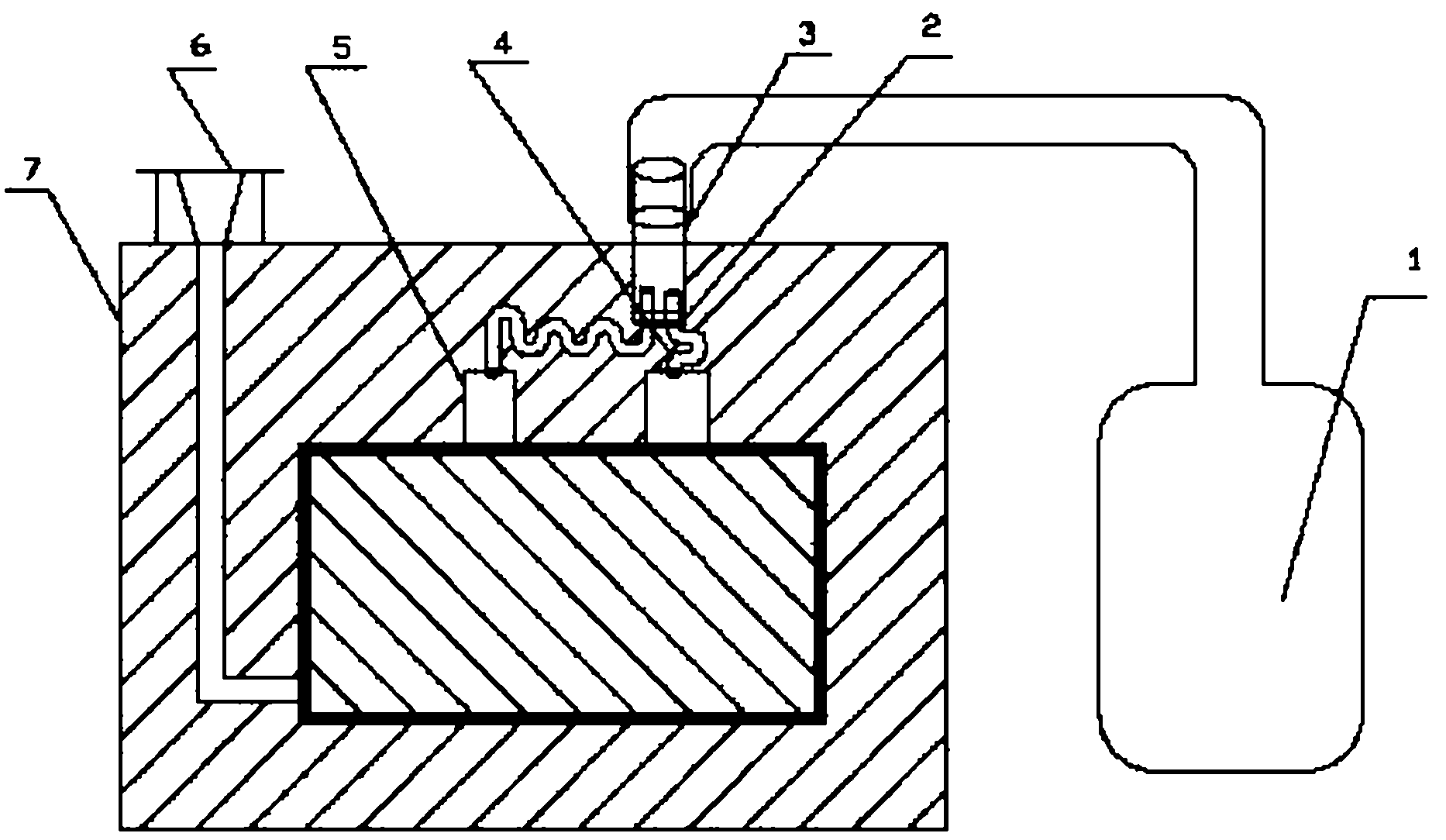

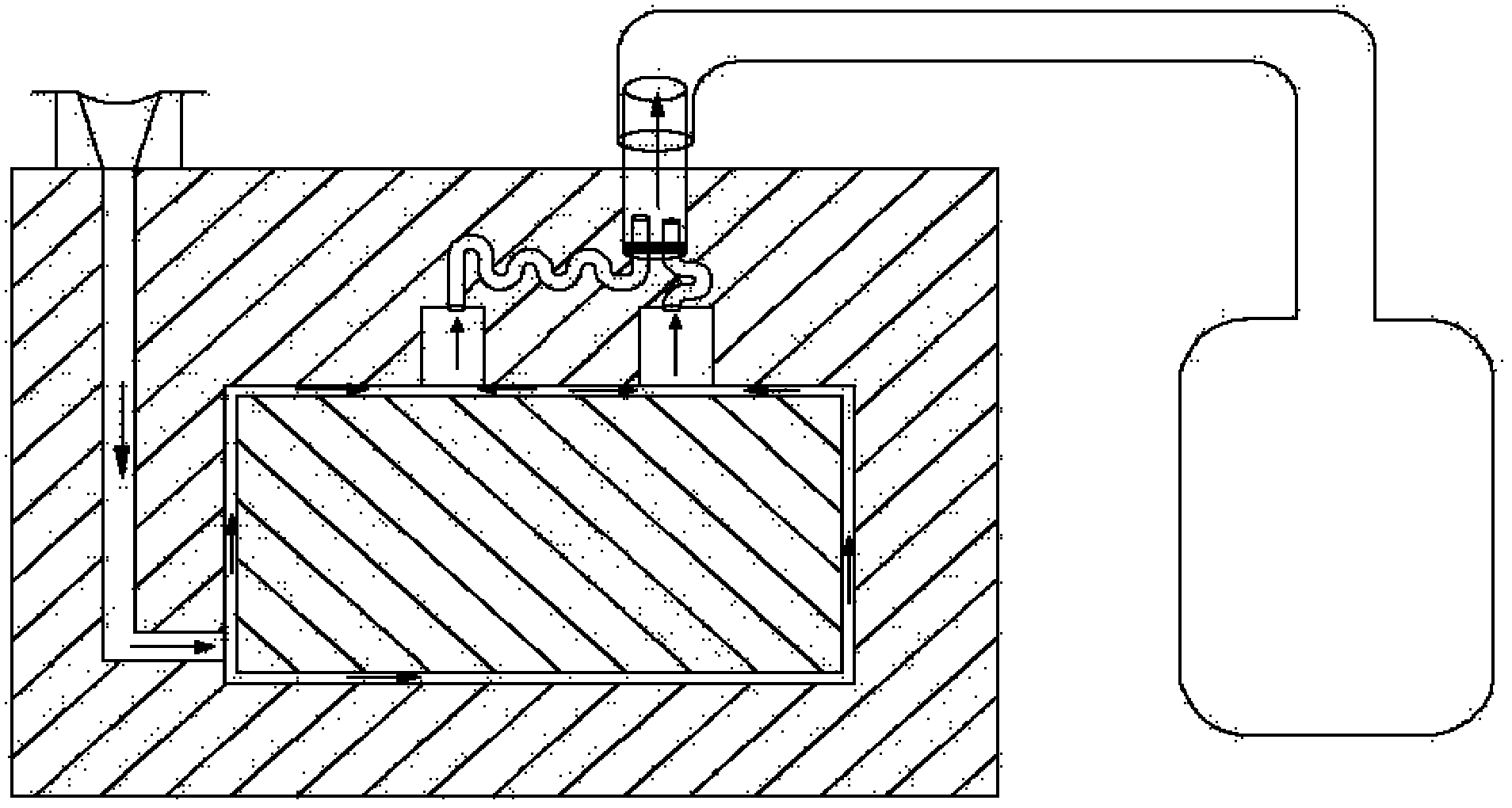

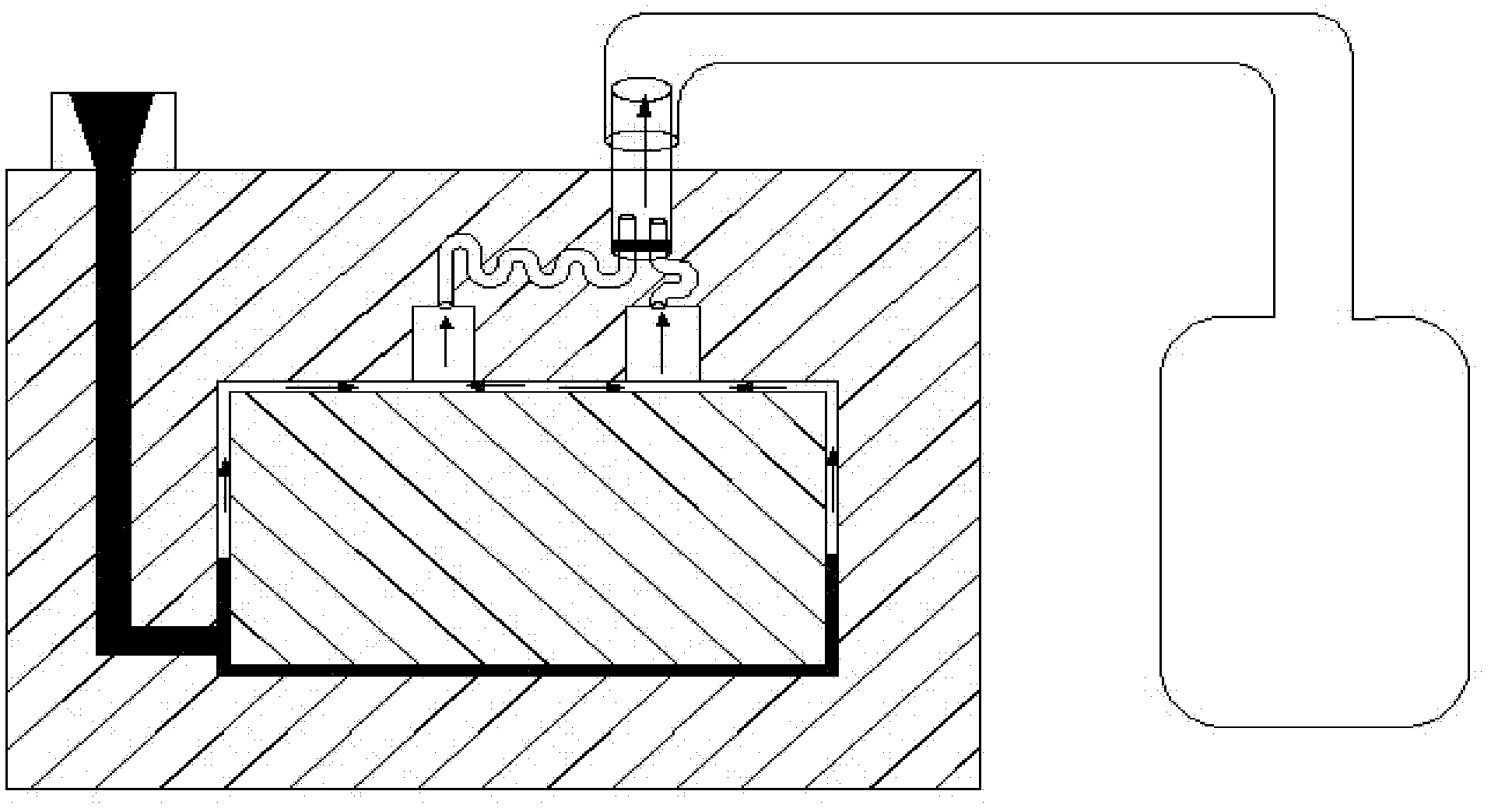

[0016] (1) prepare the slurry, and place 4 thin steel pipes 4 (diameter is 4mm) at different positions of the process boss 5 in the mold cavity, lead the outlet of the thin steel pipes 4 to the top of the gypsum mold 7, and connect to In a thick vacuum tube 3, the gap between the thin steel tube 4 and the thick vacuum tube 3 is blocked with a plastic film 2 to prevent the slurry from entering the plug hole when grouting. Manually stir the prepared gypsum mixed slurry slowly to remove air bubbles in the slurry as much as possible, pour the mixed slurry into the sand box, and apply vibration on the sand box while grouting until the grouting is completed;

[0017] (2) After the gypsum mixture is hardened, remove the sand box, and move the gypsum type 7 into the oven.

[0018] (3) Take out the dried gypsum m...

Embodiment 2

[0019] Example 2: It is required to adopt gypsum mold precision casting technology to cast an aviation cast magnesium AZ91 cylindrical part, the size of which is 1200mm in diameter, 200mm in height and 6mm in wall thickness.

[0020] (1) prepare the slurry, and place 5 thin steel pipes 4 (diameter is 8mm) at different positions of the process boss 5 in the mold cavity, lead the outlet of the thin steel pipes 4 to the top of the plaster mold 7, and connect them to a In the thick vacuum tube 3, the gap between the thin steel tube 4 and the rough vacuum tube 3 is blocked with a plastic film 2 to prevent the grout from entering the plugged tube hole. Manually stir the prepared gypsum mixed slurry slowly to remove air bubbles in the slurry as much as possible, pour the mixed slurry into the sand box, and apply vibration on the sand box while grouting until the grouting is completed;

[0021] (2) After the gypsum mixture is hardened, remove the sand box, and move the gypsum type 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com