Coacervation technology for polymer product production

A process and product technology, applied in the field of styrene-butadiene-styrene block copolymer (SBS) water analysis coagulation process, which can solve the problem of direct discharge of organic matter, high solvent consumption, and easy fluctuation of the liquid level of the coagulation tank, etc. problem, achieve the effect of reducing water content and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

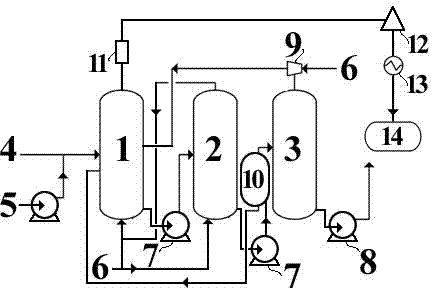

[0031] A coagulation process for the production of a polymerization product of the present invention, its technological process is referred to figure 1 . Among them, the thickener manufacturer is Tianjin Binhai New Area Shengshi Dongran Technology Development Co., Ltd., and the model is DR-III. Among them, the process conditions of each kettle are: the top pressure of the coagulation kettle is 1# kettle pressure is 10 Kpa-30 Kpa, the 2# kettle pressure is 70Kpa-90Kpa, the 3# kettle pressure is 3Kpa-7Kpa; the temperature of the coagulation kettle bottom is 1# The temperature of the kettle is 89±2℃, the temperature of the 2# kettle is 105±2℃, and the temperature of the 3# kettle is 97-100℃.

[0032] A coagulation process for the production of a polymerization product of the present invention, its remarkable effects include:

[0033] 1. The biggest advantage of the present invention is that it can greatly reduce the solvent content in SBS glue, and the energy saving effect is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com