Phenylacetic emulsion-vinyl acetate/acrylic emulsion heat preservation coating

A vinegar-acrylic emulsion and thermal insulation coating technology, applied in the direction of coating and the like, can solve the problems of failing to achieve the double-layer effect of thermal insulation decoration, affecting the decorative effect, restricting the promotion and application, etc., and achieving the effect of good thermal insulation and thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

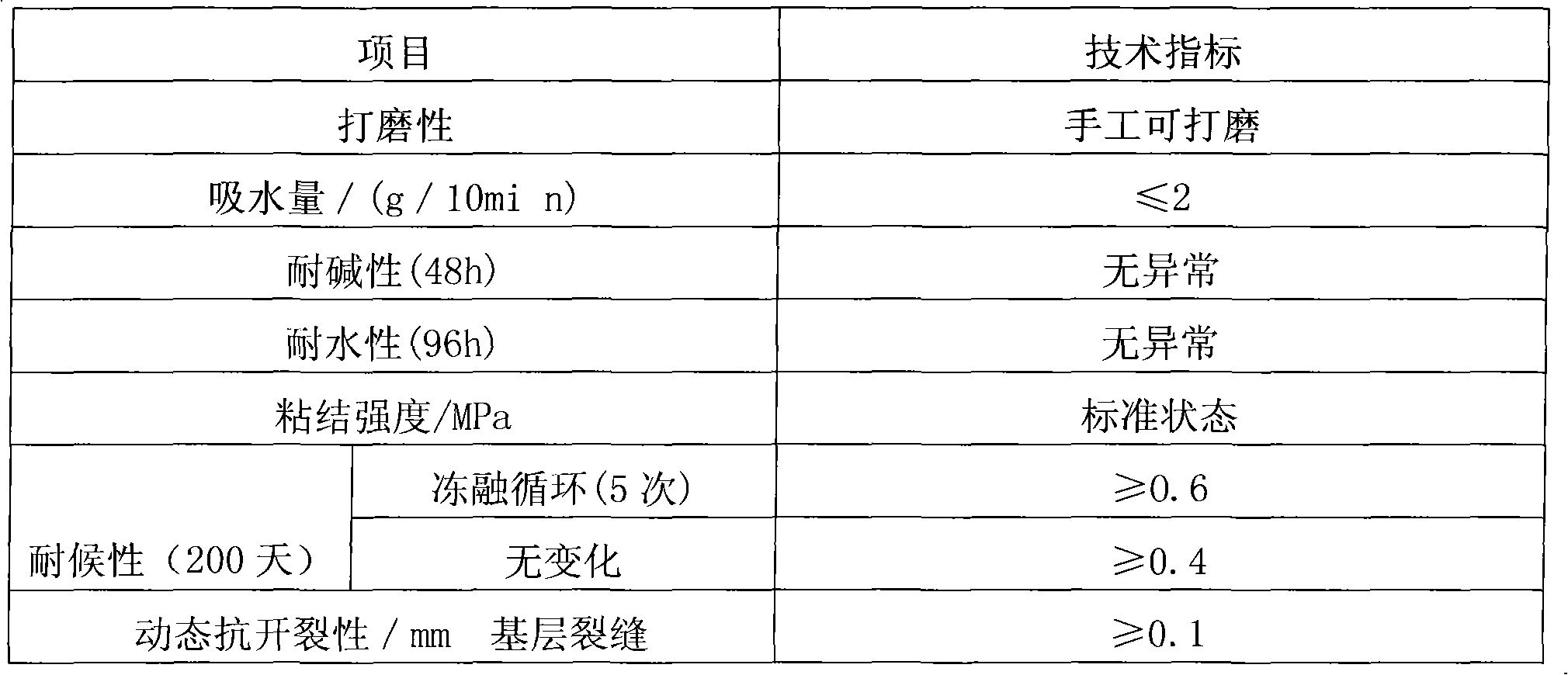

[0010] A styrene-ethyl emulsion-vinegar-acrylic emulsion thermal insulation coating is uniformly prepared by high-speed dispersion and stirring of the following raw materials according to the weight ratio: 60 parts of styrene-ethyl emulsion, 70 parts of vinegar-acrylic emulsion, 40 parts of closed-cell perlite, and 26 parts of water glass , 12 parts of diatomaceous earth, 10 parts of bamboo short fiber, 12 parts of silver nitrate, 5 parts of triethanolamine, 10 parts of potassium silicate, 10 parts of amyl acetate, 6 parts of binder, 55 parts of water, 5 parts of preservative, 15 parts of kaolin, 7 parts of thickener, 6 parts of coalescent. The main technical performance of the product prepared by the present invention is as follows table 1

[0011] Table 1, main technical performance of the present invention

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com