Graphene filling isotropic high-performance conducting adhesive and preparation method thereof

An isotropic, graphene-based technology, applied in the direction of conductive adhesives, adhesives, epoxy glue, etc., can solve the problems of low conductivity and low bonding strength, and achieve high conductivity, low cost and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

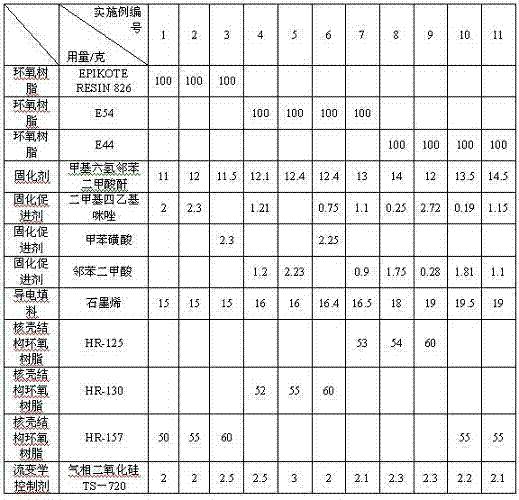

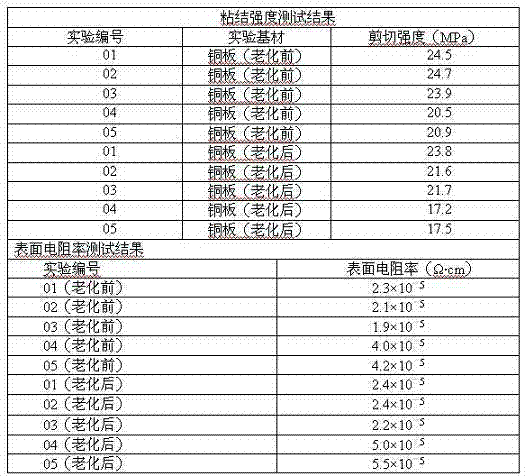

Embodiment 1~11

[0039] According to the ingredients and dosage listed in Table 2, weigh the matrix epoxy resin and the core-shell structure toughened epoxy resin and mix them. The mixing method is mechanical stirring at a stirring rate of 1000 rpm for 10 minutes. Then add the weighed surface-treated graphene and fumed silica to the mixture in a stirring state. After the addition, continue to stir for 10 minutes. After mixing evenly, add a curing agent and a curing accelerator to the mixture, and mechanically stir. After 5 minutes, the mixture was transferred to a high-speed shear mixer for mixing, and the mixing rate was 2000 rpm, and the time was 30s. Repeat the mixing process in the high-speed shear mixer for 3 times to obtain a uniform jelly. Conductive plastic.

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com