Energy-saving environmentally-friendly reduction converter

An energy-saving and environment-friendly converter technology, which is applied in the direction of rotary drum furnaces, furnaces, furnace types, etc., can solve the problems of long reduction time, heat waste in the cooling section, and harsh requirements for raw materials, so as to achieve high concentration of reducing gas and increase the discharge rate , The effect of improving the reduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

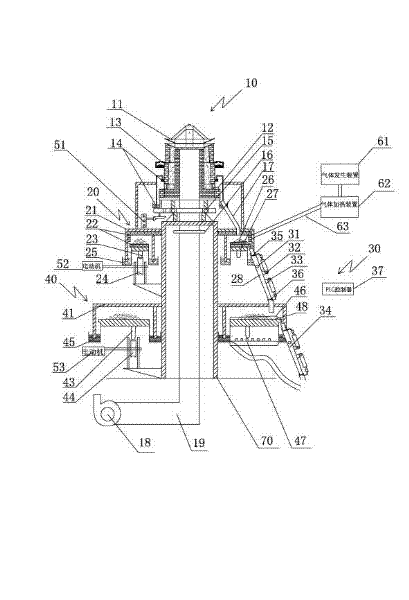

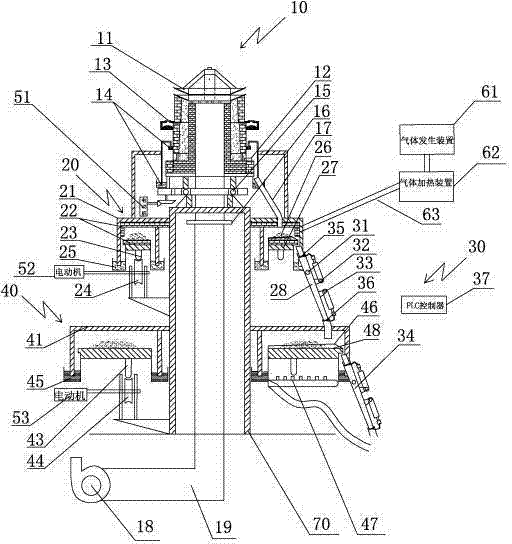

[0019] An energy-saving and environment-friendly reduction converter, which includes a furnace body (10), a reduction device (20), a cooling device (40), a gas generating device (61), a gas heating device (62) and a support (70), the furnace body (10 ) includes a fan (18) and an air duct (19), the furnace body (10), the reducing device (20) and the cooling device (40) are vertically arranged up and down on the same axis; the furnace body (10) is installed on the rotary table (15 ), the motor I (51) drives the rotary table (15) to rotate, and a sealing ring (16) is provided on the air channel (19) below the rotary table (15); the reduction device (20) is: a reduction disk ( 27) is provided with an iron cover I (21), and the iron cover I (21) is fixedly connected with the support (70). The edge of the reduction disk (27) is provided with a sand seal II (25), and the sand seal II (25) is connected with The restoration disk (27) is fixedly connected, and the ball I (23) is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com